Automatic polishing and picking device for bamboo toothpicks

An automatic polishing and toothpick technology, which is used in grinding/polishing equipment, surface-polished machine tools, and the manufacture of wooden sticks. efficiency, meeting the needs of mass production of products, excellent practicability and creative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

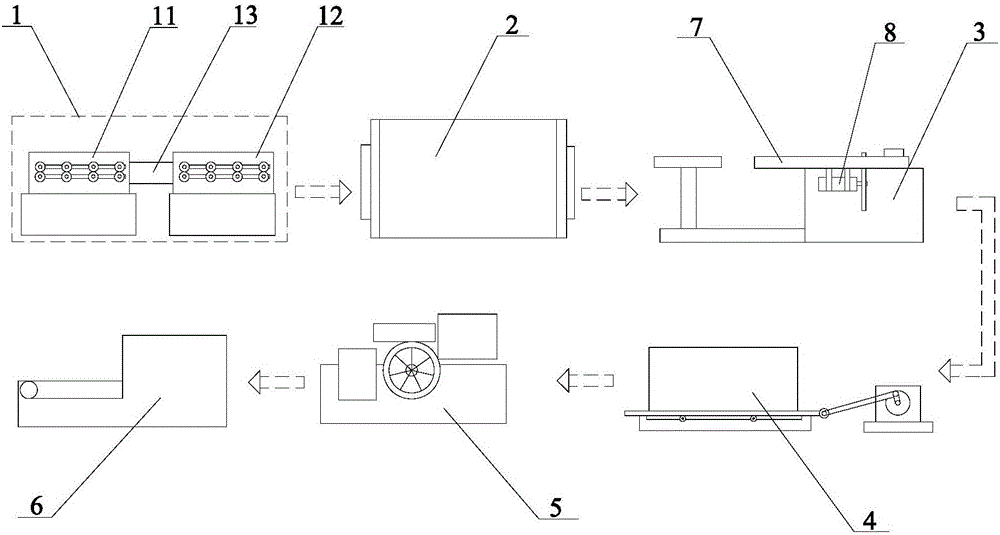

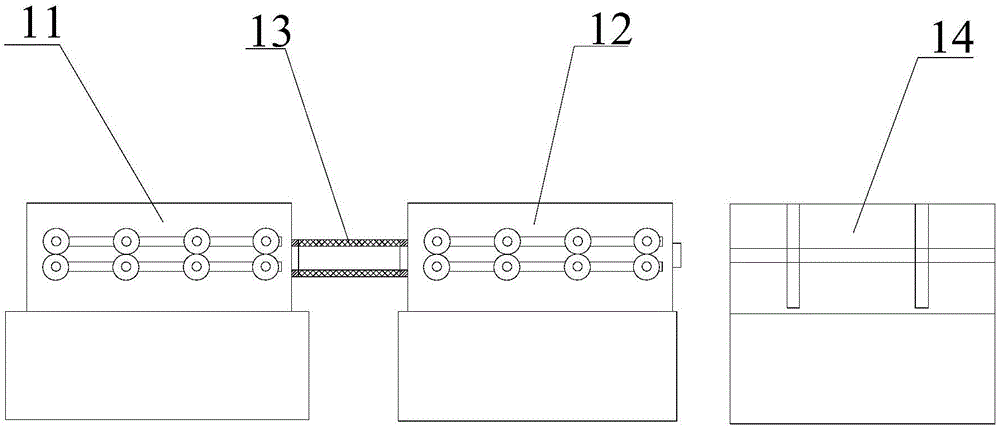

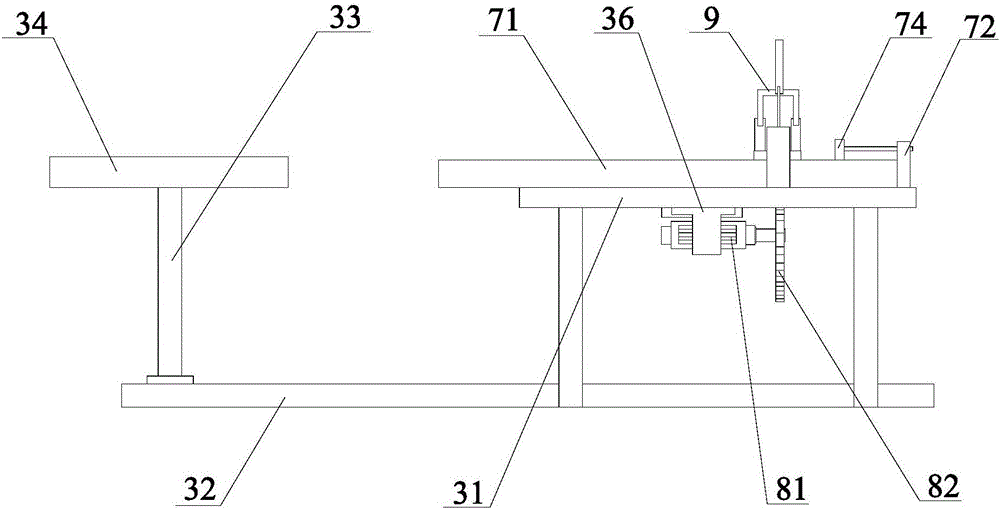

[0015] Such as figure 1 As shown, a bamboo toothpick processing system, according to the processing flow, sequentially includes a conjoined wire drawing machine 1, a drying and carbonization chamber 2, a material cutting device 3, an automatic polishing and sorting device 4, a toothpick grinding device 5 and a packaging machine 6 ; Wherein, the conjoined spinning machine 1 is used to process bamboo chips into bamboo filaments of a certain specification, the dry carbonization chamber 2 is used for drying and carbonizing bamboo filaments, and the cutting device 3 is used for drying and carbonizing bamboo filaments. The final bamboo shreds are cut into fixed-length toothpicks, and the automatic polishing and sorting device 4 is used to polish the toothpicks, and the defective products are automatically picked out simultaneously, and the toothpick grinding device 5 is used to polish the toothpicks. The end of the rod is ground and processed to obtain a toothpick of a certain speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com