Automated medicine box packaging line

A packaging line and medicine box technology, which is applied in the field of automated medicine box packaging line, can solve the problems of low detection accuracy, increased workload, and low degree of automation, and achieve the effects of improving transmission efficiency, reducing labor intensity, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

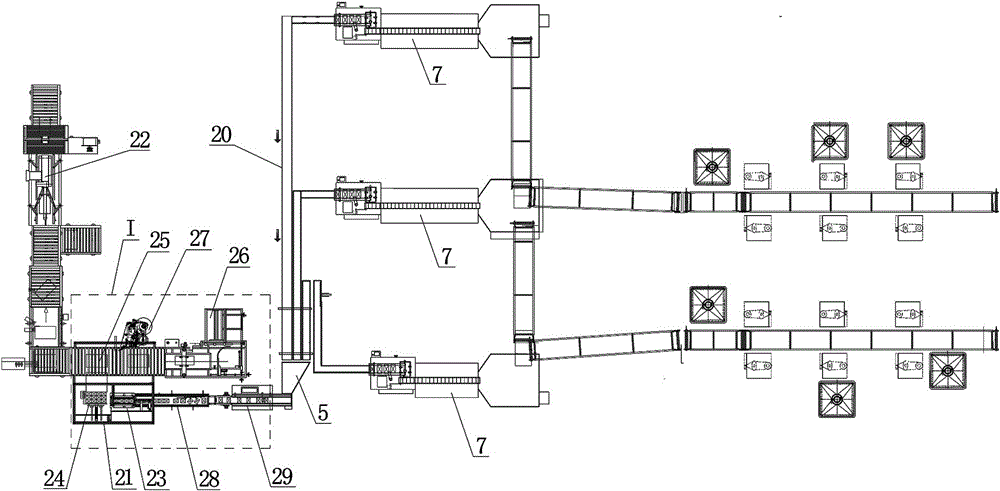

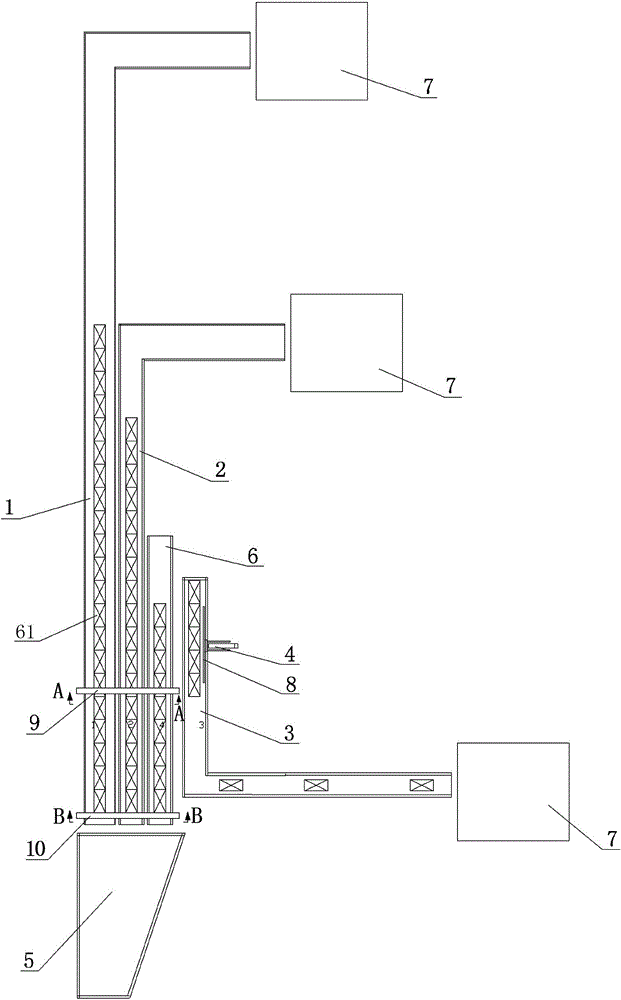

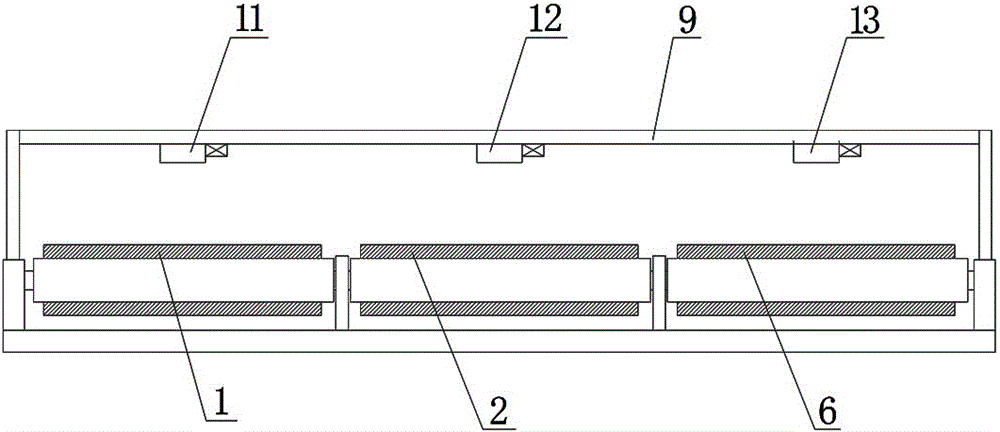

[0027] Such as figure 1 and Figure 9 As shown, a kind of automatic medicine box packaging line, it comprises diversion and channel system 20, intermediate conveyer belt 5, packaging machine 21 and sealing machine 22, described packaging machine 21 is composed of stacking box device 23, stacking device 24, Conveyor roller table 25, case unpacking machine 26 and labeling machine 27 are composed, the output end of case unpacking machine 26 is docked with one end of conveying roller table 25, and the other end of conveying roller table 25 is docked with the inlet end of case sealing machine 22, labeling The machine 27 is arranged on the side of the conveying roller table 25, and a medicine box straightening device 28 and a medicine box shape detection device 29 are sequentially arranged between the box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com