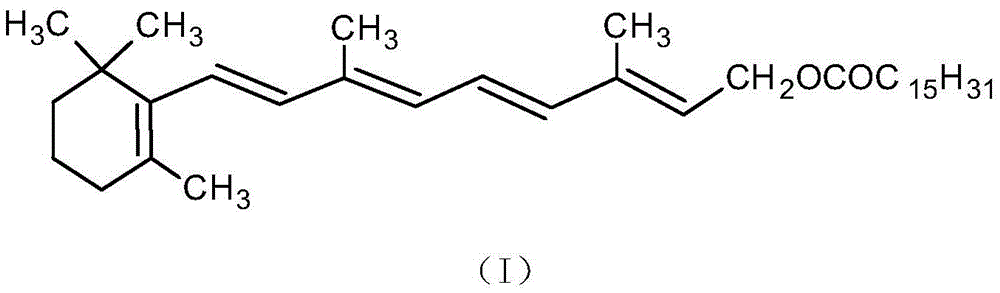

Synthesis method of vitamin A palmitate

A technology of palmitate and synthesis method, applied in directions such as fermentation, can solve problems such as low yield and high instability of vitamin A alcohol, and achieve the effect of avoiding influence and reducing the difficulty of separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

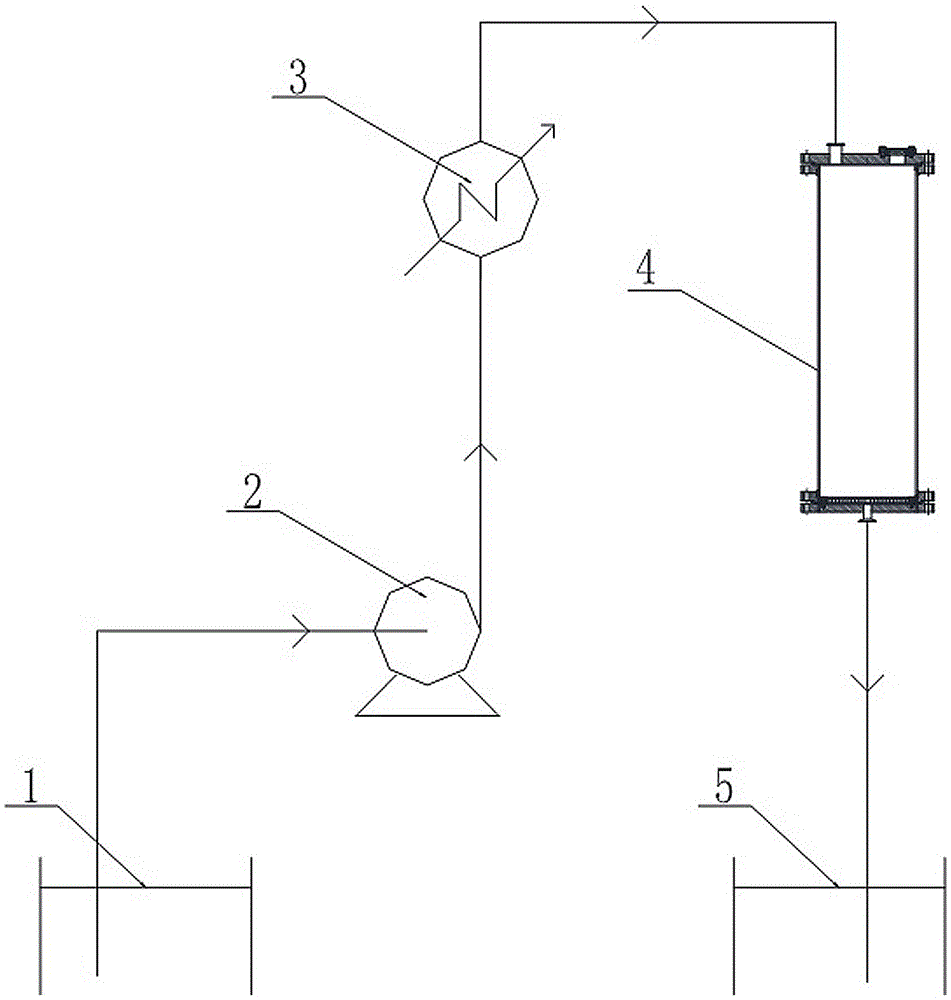

[0037] Cooperate figure 1 As shown, vitamin A acetate (20g) and palmitic acid (52g) are dissolved in n-hexane (480g), put into the raw material tank 1, set the flow rate at 10ml / min, and deliver the above solution to the pre- In the heater 3, it is preheated to 40°C through the preheater 3, and then sent to the reaction column 4 for reaction, and the reaction process controls the reaction temperature to remain at 40°C; the reaction column is filled with Novozyne435 (120g) and Amberlyst A21 (60g), Mix both well. The reaction solution was cooled to crystallization, and the filtrate was concentrated to obtain a light yellow oil, which was then sent to the product tank 5. The resulting oil was analyzed according to the method of United States Pharmacopoeia USP28. The results showed that the content of vitamin A palmitate was 95.63%. The conversion rate was 96.93%.

Embodiment 2

[0039] Same fit figure 1 As shown, dissolve vitamin A acetate (1g) and palmitic acid (2.6g) in n-hexane (24g), add Novozyne435 (0.25g) and Amberlyst A21 (0.5g), place in a shaker, adjust the speed at 250rpm, The reaction temperature was maintained at 40°C; the reaction was 6h. The reaction solution was filtered and cooled to crystallization, and the filtrate was concentrated to obtain a pale yellow oil. The resulting oil was analyzed according to the method of United States Pharmacopoeia USP28. The results showed that the content of vitamin A palmitate was 88.63%. The conversion rate was 90.93%.

Embodiment 3

[0041] With embodiment 1, palmitic acid quality is changed into 56g. The resulting oil was analyzed according to the method of United States Pharmacopoeia USP28. The results showed that the content of vitamin A palmitate was 97.71%. The conversion rate is 97.95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com