Additive Manufacturing System for Rapid Deposition on Workpiece Surfaces by Vacuum Plasma

A workpiece surface and plasma technology is applied in the additive manufacturing system to rapidly form high-performance thick coatings, which can solve the problems of poor coating effect, low coating deposition efficiency and thin coating thickness on complex workpieces. To achieve the effect of reducing the probability of delamination, increasing the binding force and increasing the adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

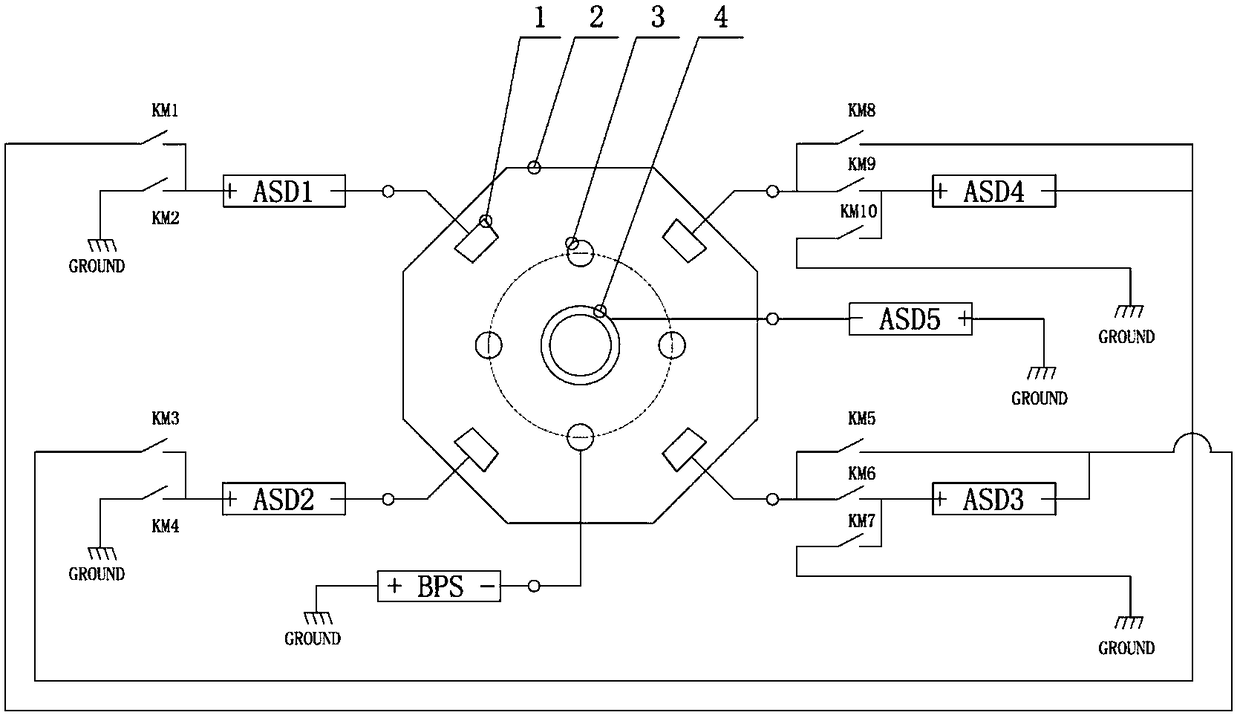

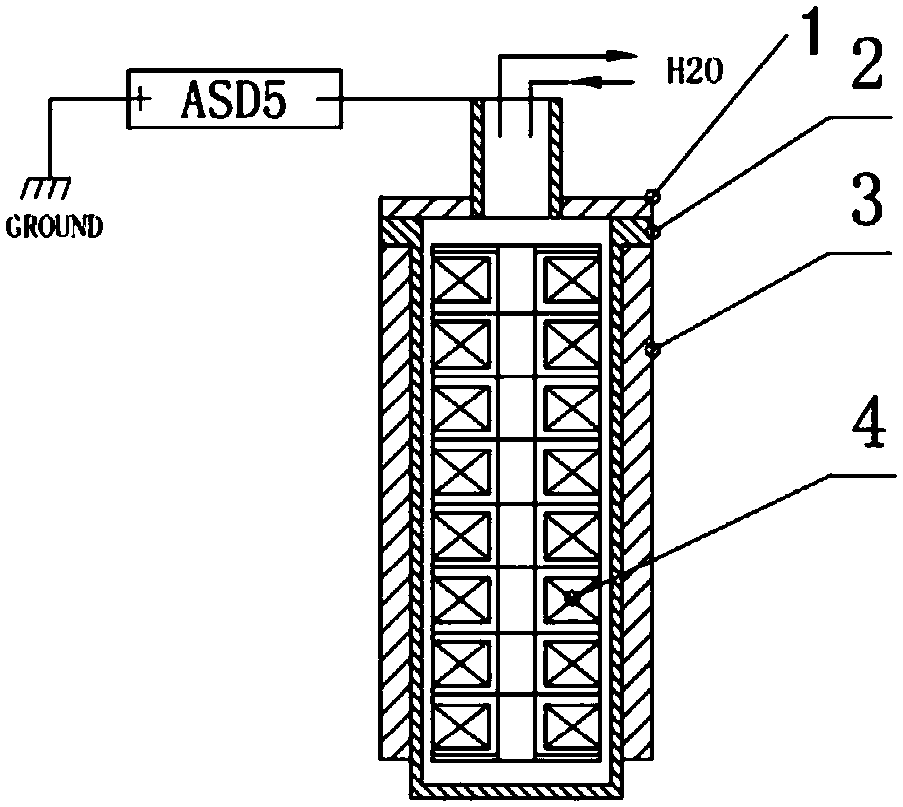

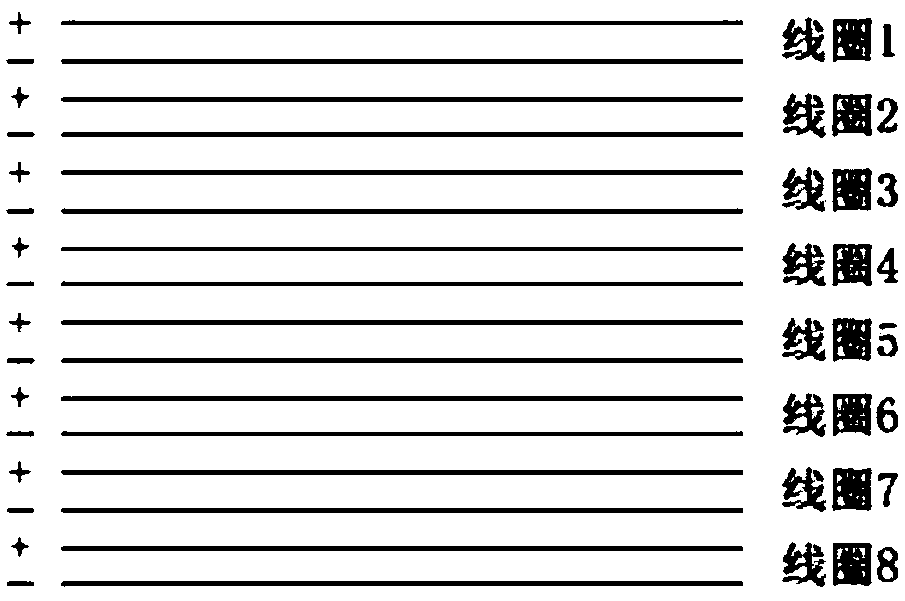

[0038] refer to Figure 1 to Figure 5 , the present embodiment includes a vacuum obtaining and measuring device 1 and a vacuum chamber 10, the vacuum obtaining and measuring device 1 communicates with the vacuum chamber 10 through a vacuum pipeline 2, and a plurality of side wall cathode target pairs are installed on the side wall of the vacuum chamber 10, A columnar cathode target 4 and a rotary support mechanism 3 are installed in the center of the vacuum chamber 10. The columnar cathode target 4 has a high-power and high-current structure. The columnar cathode target 4 is connected to a high-power arc power supply to output a large current. The columnar cathode target The power input terminal of 4 is connected to the output terminal of the PLC control system, and the positive and negative input switches are repeatedly performed through the PLC control system to change the direction of the electromagnetic field acting on the target surface of the columnar cathode target 4, so...

specific Embodiment 2

[0072] The characteristics of this embodiment 2 are: the vacuum chamber 10 is an equilateral octagon with eight rectangular surfaces, one of which is connected to the vacuum obtaining system and its measuring device 1 through the vacuum pipeline 2, and the other seven rectangular surfaces have rectangular openings 1. It is used to connect the rectangular flange. A cathode target 23 is installed on each of the six rectangular flanges. The cathode target 23 is externally connected with a cathode arc power input device 24 and a cooling water inlet and outlet device 25. The cathode target 23 An electromagnetic field 22 is provided around the , forming three pairs of sidewall cathode targets. All the other are with specific embodiment 1.

specific Embodiment 3

[0073] refer to Figure 6 to Figure 8 , the feature of the specific embodiment 4 of the present invention is that the structure of the vacuum chamber 10 can be circular, and four to eight windows are formed on the circumference, one of which is connected to the vacuum obtaining system and its measuring device 1 through the vacuum pipeline 2, and the other three to The seven windows are arc-shaped rectangular openings (rectangular projection), used to connect flanges, and cathode targets 23 are installed on the flanges of four or six windows, and the cathode targets 23 are externally connected to the cathode arc power input. The device 24 and the cooling water inlet and outlet device 25 are provided with an electromagnetic field 22 around the cathode target 23 to form two or three pairs of side wall cathode targets. All the other are with specific embodiment 1 or specific embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com