Horizontally-opposed cylindrical cam engine

A cylindrical cam, horizontally opposed technology, applied in the direction of machines/engines, cams, mechanical equipment, etc., can solve the problems of sudden changes in speed, large volume, etc., and achieve the effects of extended life, reduced volume, and good power output stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

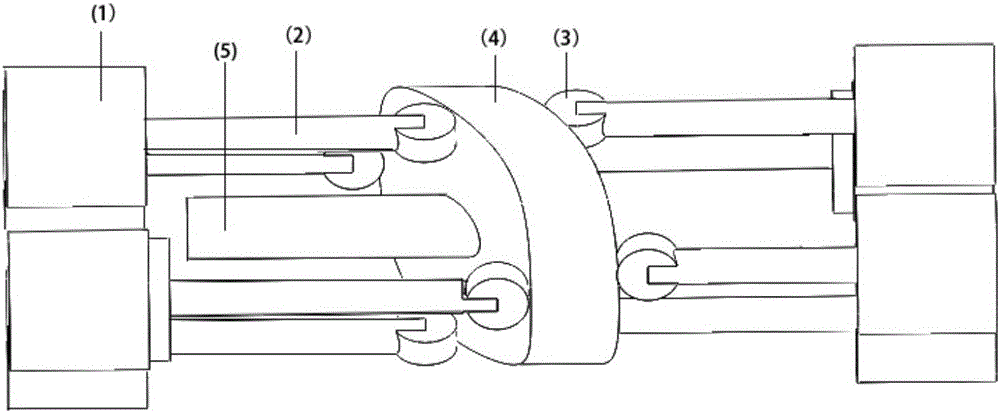

[0021] A horizontally opposed cylindrical cam 4 engine, comprising a horizontally placed cylindrical cam 4, the contour lines of the left and right end surfaces of the cylindrical cam 4 are laterally undulating curves, and a power shaft 5 is fixed in the center of the cylindrical cam 4; the left and right sides of the cylindrical cam 4 Four pistons 1 with push rods 2 are respectively arranged on each end face, and the bottom end of said piston 1 push rod 2 is provided with a roller 3, and the roller 3 moves along the contour line of the cylindrical cam 4 end face, and the piston 1 push rod The linear reciprocating motion of 2 is converted into the rotary motion of cylindrical cam 4. The four pistons 1 on one side of the cylindrical cam 4 are symmetrically arranged around the center of the cylindrical cam 4, and the rollers 3 each have a quarter phase difference on the contour line of the end face of the cylindrical cam 4. The pistons 1 on both sides of the cylindrical cam 4 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com