A pressure sensor circuit and its debugging method

A technology of pressure sensor and voltage amplifying circuit, which is applied in the field of pressure sensor circuit and its debugging, which can solve the problems of output signal reduction, bridge output signal circuit noise sensitivity, instability, etc., achieves low static consumption current and meets debugging requirements , the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

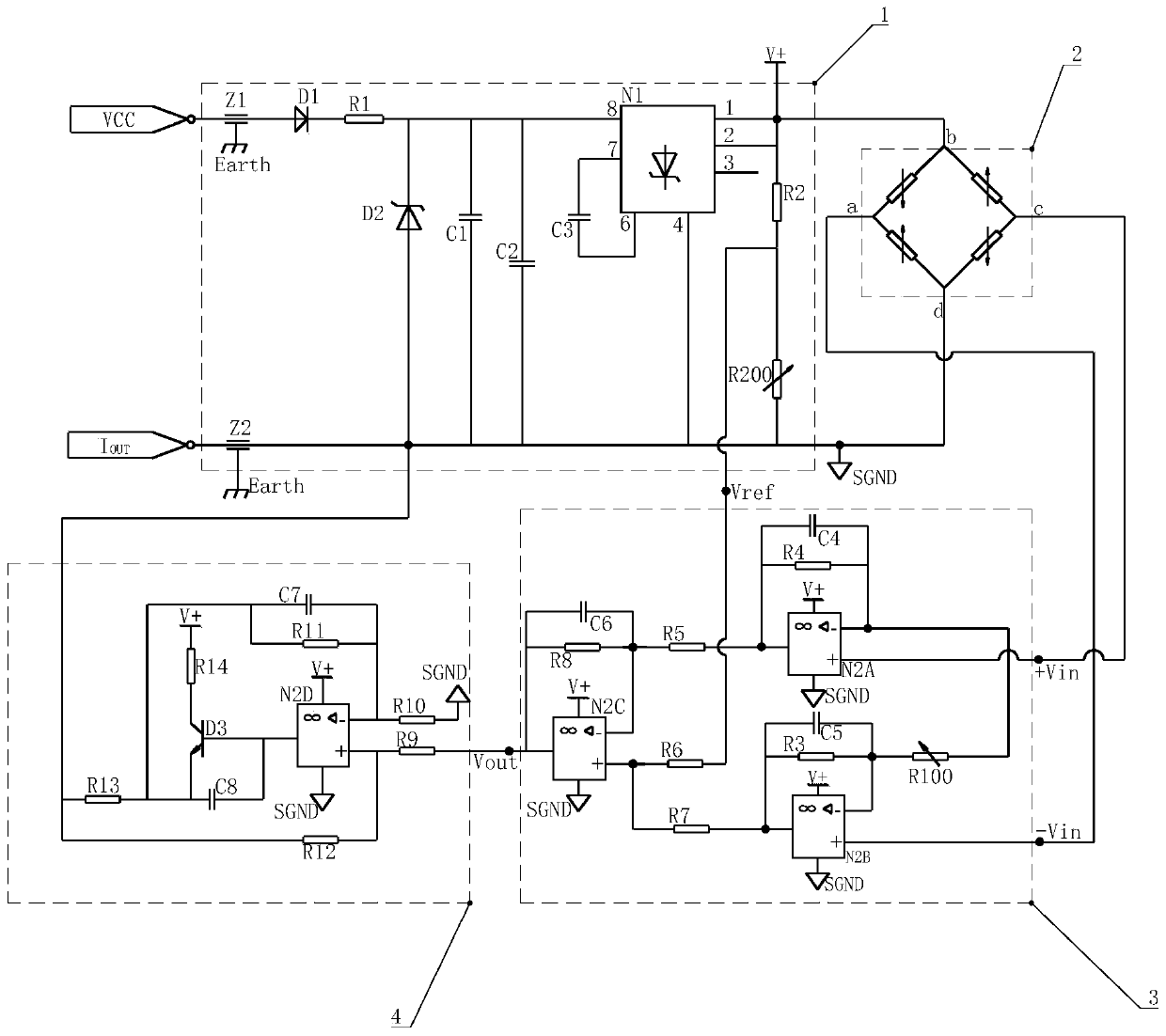

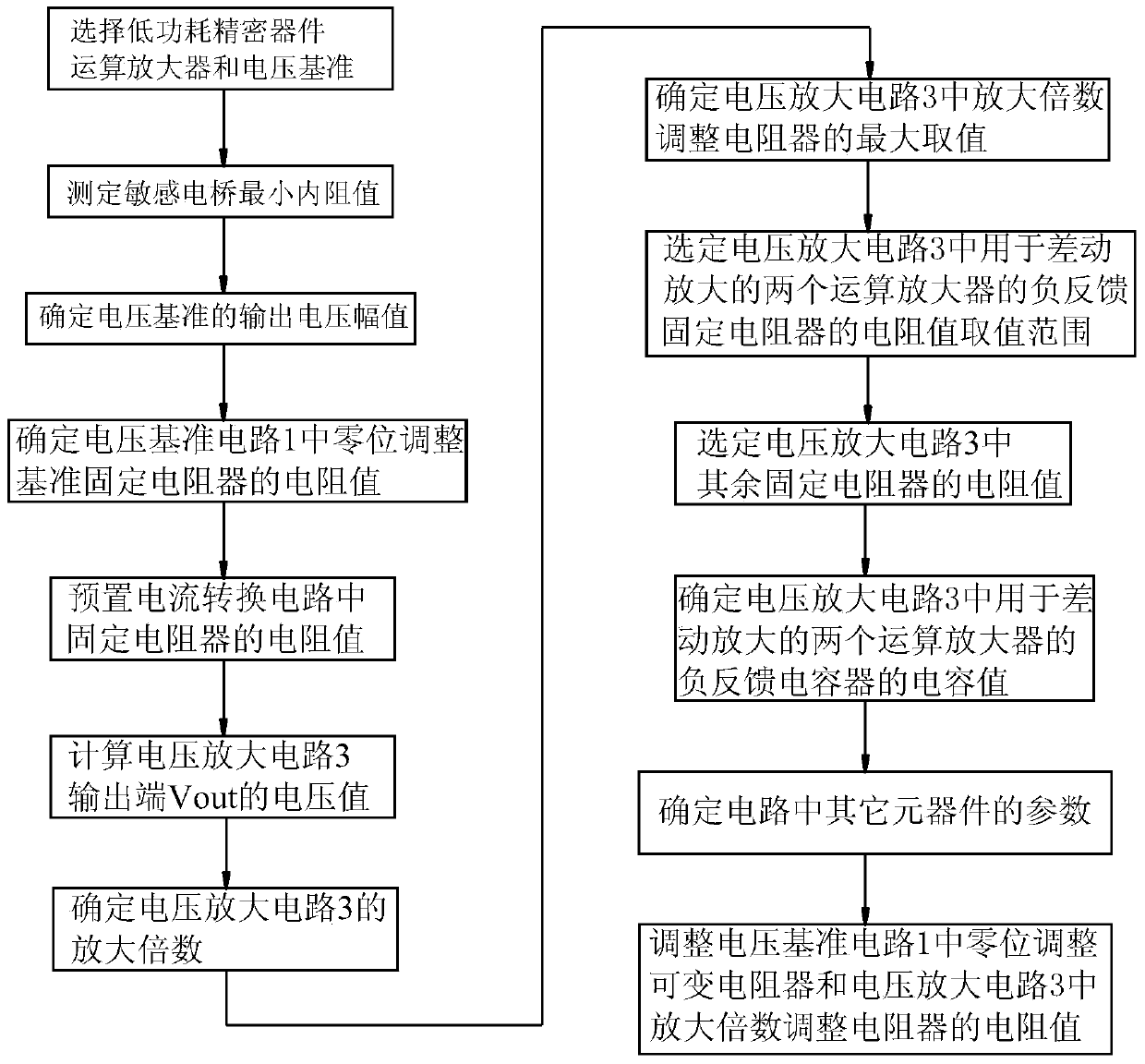

[0059] Such as figure 2 As shown, the sensitive bridge 2 is a sputtered thin-film pressure sensitive bridge with an output sensitivity of 1.5mV, the minimum bridge resistance of the sensitive bridge is 3.2kΩ, and the minimum zero output voltage is 0.1mV. The implementation steps are as follows:

[0060] Step 1. Select a low-power precision device op amp and voltage reference:

[0061] according to figure 1 The circuit selects the main low-power precision devices as operational amplifiers and voltage references.

[0062] The selection condition of operational amplifier is: low static consumption current: the maximum static consumption current summation of described operational amplifier N2A, N2B, N2C and N2D four operational amplifiers is I 1 , then there should be I 1 ≤1.5mA; allow normal operation under single power supply, low voltage input conditions; output voltage amplitude as close as possible to the working power supply voltage, especially for rail-to-rail operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com