Method for detecting heavy metals in wastewater

A detection method and heavy metal technology, which is applied in the field of analytical chemistry, can solve the problems of low detection results and difficulty in accurately detecting heavy metals, and achieve the effects of improving sensitivity, detection accuracy, and integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

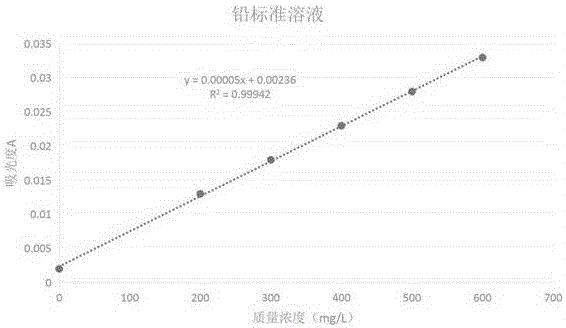

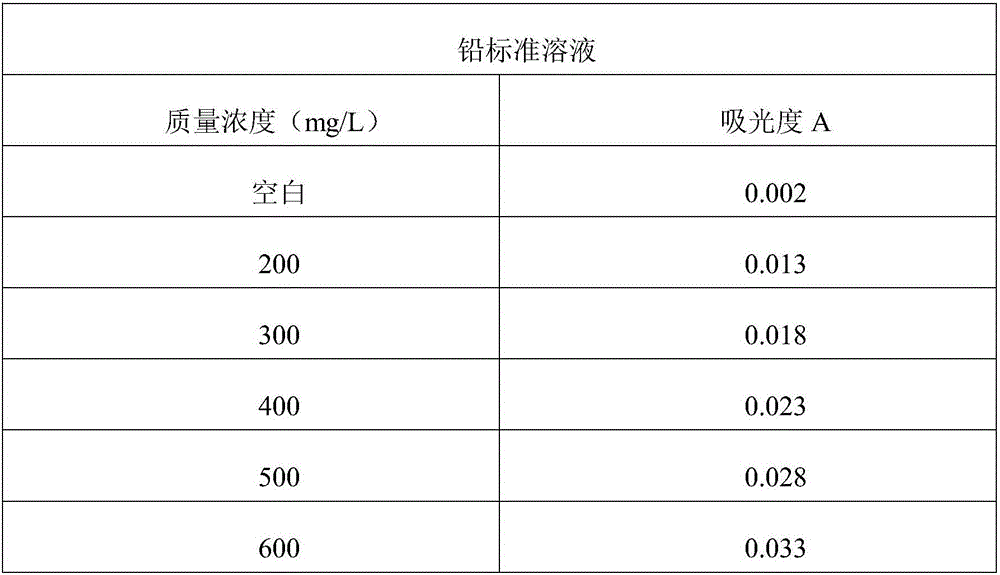

Embodiment 1

[0031] Example 1, randomly select a bottle of collection liquid, set up three groups of parallel experiments to carry out the following steps:

[0032] Step S1, take 100ml of collection liquid and use a laboratory vacuum filtration device to carry out vacuum filtration through a 4.5 micron filter membrane and use a 100ml test tube to receive 70-80ml of filtrate, and use a pipette to remove part of the filtrate from the test tube to obtain the remaining 50ml for testing liquid;

[0033] Step S2, pour the solution to be tested obtained in step S1 into a polytetrafluoroethylene tube, and add 25ml of secondary deionized water to rinse the test tube and add it into the polytetrafluoroethylene tube;

[0034] Step S3, use a 2ml pipette to transfer 2ml of concentrated nitric acid with a concentration of 16mol / L into the polytetrafluoroethylene tube, take another 2ml pipette to transfer 1.5ml hydrogen peroxide into the polytetrafluoroethylene tube, and use a glass dropper to transfer t...

Embodiment 2

[0040] Example 2, select a bottle of collection solution with low mass concentration, and set up three groups of parallel experiments to perform the following steps:

[0041] Step S1, take 100ml of collection liquid and use a laboratory vacuum filtration device to carry out vacuum filtration through a 4.5 micron filter membrane and use a 100ml test tube to receive 70-80ml of filtrate, and use a pipette to remove part of the filtrate from the test tube to obtain the remaining 50ml for testing liquid;

[0042] Step S2, pour the solution to be tested obtained in step S1 into a polytetrafluoroethylene tube, and add 25ml of secondary deionized water to rinse the test tube and add it into the polytetrafluoroethylene tube;

[0043] Step S3, use a 2ml pipette to transfer 2ml of concentrated nitric acid with a concentration of 16mol / L into the polytetrafluoroethylene tube, take another 2ml pipette to transfer 1.5ml hydrogen peroxide into the polytetrafluoroethylene tube, and use a glas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com