Processing technology for embedded type glass-fiber-woven flame-retardant cotton-covered wire

A wire processing and flame retardant fabric technology, applied in circuits, insulated cables, electrical components, etc., can solve the problems of large smoke production, long burning distance, increased water permeability, etc. The effect of reducing the fire area and suppressing the combustion reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] An embedded glass fiber braided flame-retardant cloth electric wire processing technology proposed by the present invention comprises the following steps:

[0022] A), the insulation layer is extruded outside the conductor;

[0023] B), braiding the glass fiber layer outside the edge layer;

[0024] C), extruding low-smoke, halogen-free and flame-retardant polyolefin on the glass fiber layer to form a glass fiber embedded layer;

[0025] D), the outer periphery of the glass fiber embedded layer is extruded with an assembly layer along the axial direction of the conductor;

[0026] E), cutting along the circumference of the glass fiber layer at multiple places in the assembly layer to form multiple flow guides;

[0027] F), coating the temperature-sensitive color-changing paint on the diversion part.

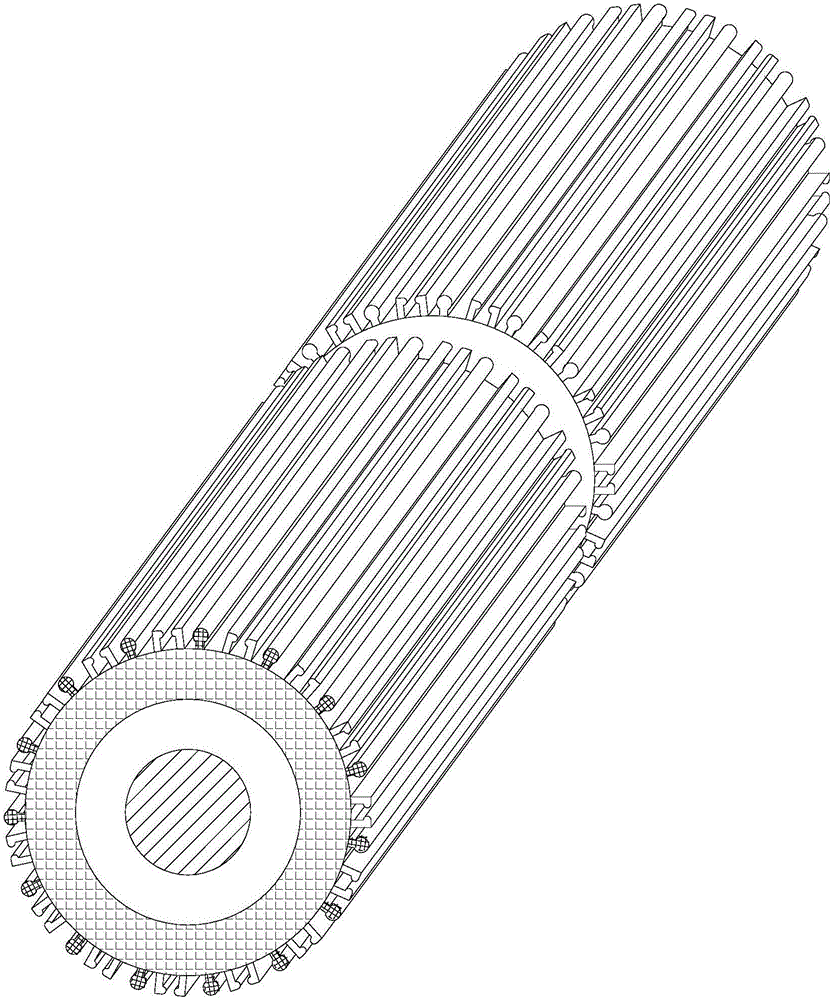

[0028] figure 1 It is a structural schematic diagram of the cable produced by the embedded glass fiber braided flame-retardant cloth electric wire processing technolog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com