A kind of green thorn leaf extract and its preparation method and application

A green thorn tip and extract technology, which is applied in the field of green thorn tip young leaf extract and its preparation and application, can solve the problems that the method of active ingredients is not easy to reproduce, not suitable for popularization and application, and low yield, etc., to achieve suitable Popularization and application, good anti-aging, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

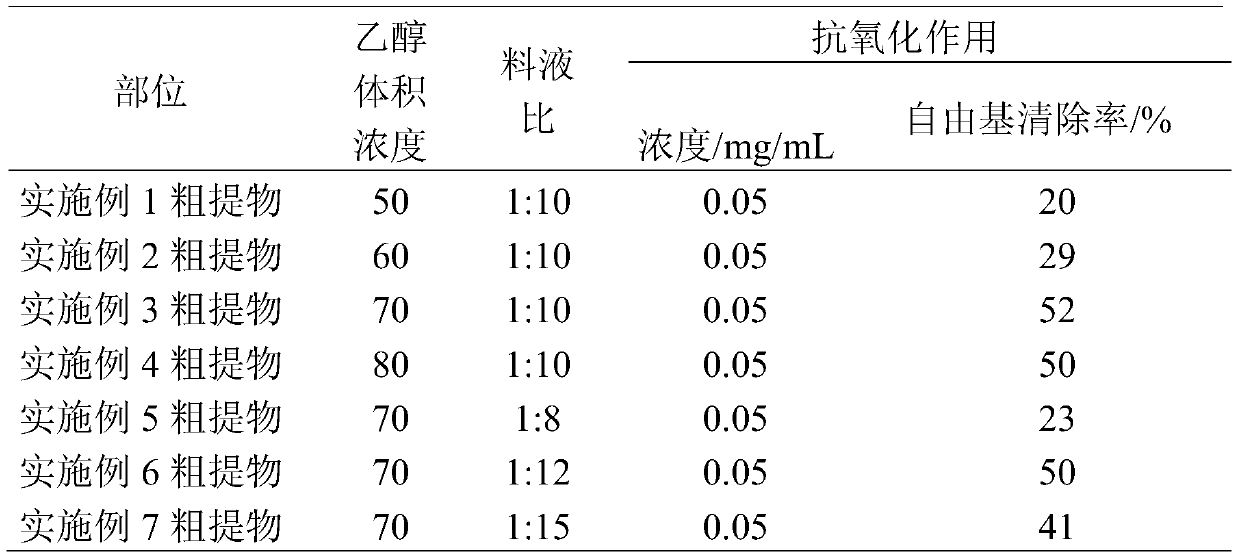

Embodiment 1

[0030] 20g of the dry powder of the young leaves of the green thorn, immersed in 200mL of ethanol solution with a volume concentration of 50% at room temperature, that is, the mass volume ratio (solid-liquid ratio) of the dry powder of the green thorn to the ethanol solution is 1:10, ultrasonic extraction 2 times, Each time for 30 minutes (500W), the filtrates were combined and rotary evaporated to dryness under reduced pressure to obtain 2.05 g of the crude extract of the young leaves of the green thorn, with a yield of 10.25%.

Embodiment 2

[0032] 20g of dried green thorn powder, submerged in 200mL of 60% ethanol solution at room temperature, that is, the mass volume ratio (solid-liquid ratio) of green thorn dry powder to ethanol solution is 1:10, ultrasonic extraction 2 times, each time After 30 minutes (500W), the filtrates were combined and rotary evaporated to dryness under reduced pressure to obtain 2.12 g of the crude extract of the green thorny young leaves, with a yield of 10.60%.

Embodiment 3

[0034] 20g of dried green thorn powder, immersed in 200mL of 70% ethanol solution at room temperature, that is, the mass volume ratio (solid-to-liquid ratio) of green thorn dry powder to ethanol solution is 1:10, ultrasonic extraction 2 times, each time After 30 minutes (500W), the filtrates were combined and rotary evaporated to dryness under reduced pressure to obtain 2.24 g of the crude extract of the young leaves of the green thorn, and the yield was 11.20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com