a vacuum circuit

A loop and vacuum technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of high consumption of compressed air, unmaintainable vacuum state, workpiece falling, etc., to achieve the effect of sharply reducing consumption and shortening the duration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

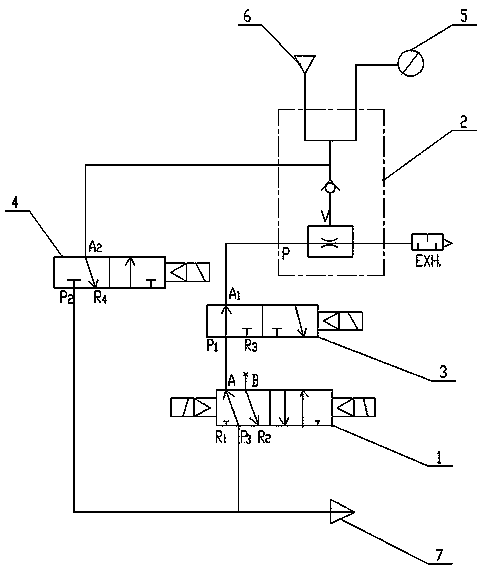

[0017] Such as figure 1 As shown, the double electric control supply solenoid valve 1 and the vacuum breaking valve 4 of the present invention are connected with the main air source 7, the main air source 7 is a compressed air source, and the double electric control supply solenoid valve 1 is connected to the vacuum generator through the energy-saving valve 3 2 is connected to the air inlet P port, the vacuum breaker valve 4 is connected to the air outlet V port of the vacuum generator 2, and a check valve is provided between the air outlet V port of the vacuum generator 2, the suction cup 6 and the negative pressure switch 5 to prevent Air flows back into the vacuum chamber from the silencer exhaust port EXH or the intake P port of the vacuum generator 2 .

[0018] The negative pressure switch 5 includes a negative pressure switch sensor and a negative pressure switch signal line; the negative pressure switch sensor is connected to the outlet V port of the vacuum generator 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com