Blockage cleaning and dust removing equipment for industrial furnace

A technology for dust removal equipment and industrial furnaces and kilns, which is applied in lighting and heating equipment, furnaces, descaling devices, etc., can solve problems such as large physical injury to operators, poor cleaning effect, and high labor intensity, and ensure smooth flue flow. , The effect of improving the efficiency of construction work and the high level of equipment generalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The principles and features of the present invention will be described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

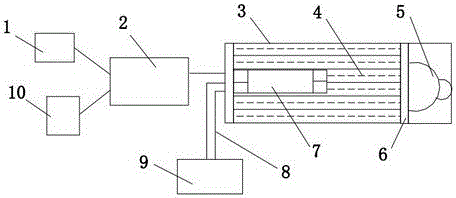

[0010] according to figure 1 As shown, the industrial kiln clearing and dedusting equipment includes an air compressor 1 and a carbon dioxide container 10, wherein the air compressor 1 and the carbon dioxide container 10 are all connected to a booster 2, and the booster 2 is connected to a carbon dioxide liquid storage pipe 3, and the carbon dioxide Liquid carbon dioxide 4 and a heating tube 7 are arranged in the liquid storage tube 3 respectively. One end of the carbon dioxide liquid storage tube 3 is connected to the detonation controller 9 through a wire 8 , and the other end is connected to the rupture piece 6 and the release port 5 in turn.

[0011] Book invention The working principle and usage steps m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com