Via hole structure, pixel structure and manufacture method of TFT (Thin Film Transistor) substrate

A technology of thin-film transistors and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, circuits, etc., can solve problems such as large-area, unfavorable narrow frontal margin manufacturing, etc., achieve area improvement, improve reliability analysis, avoid The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

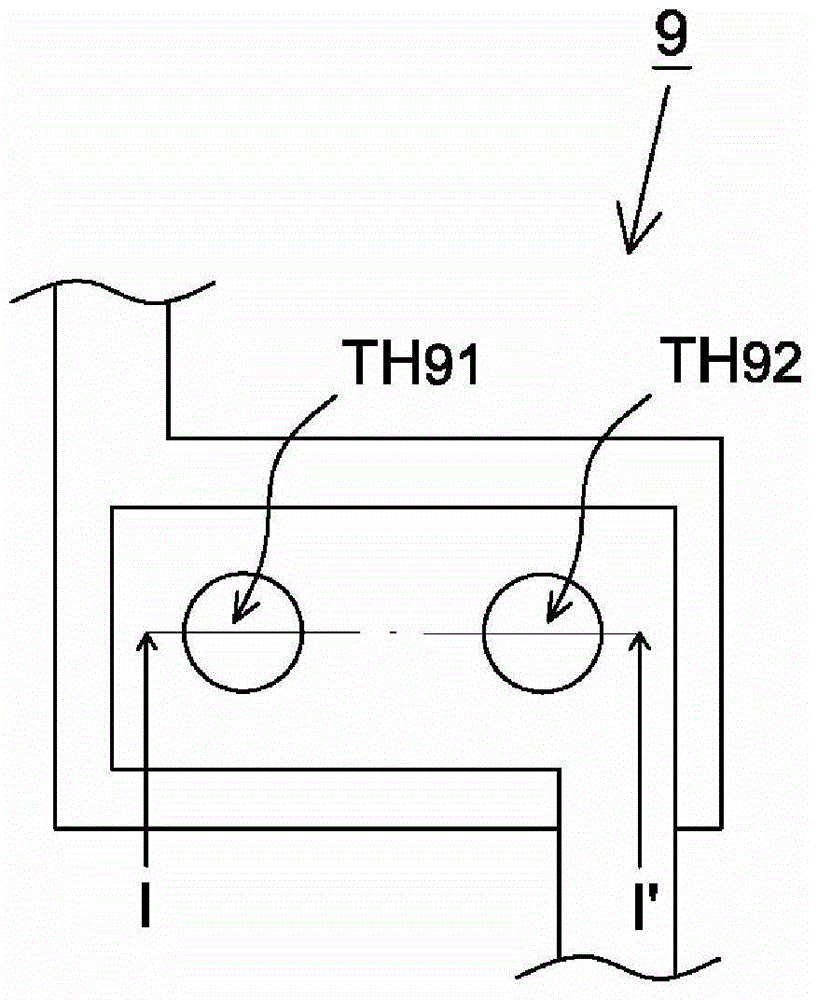

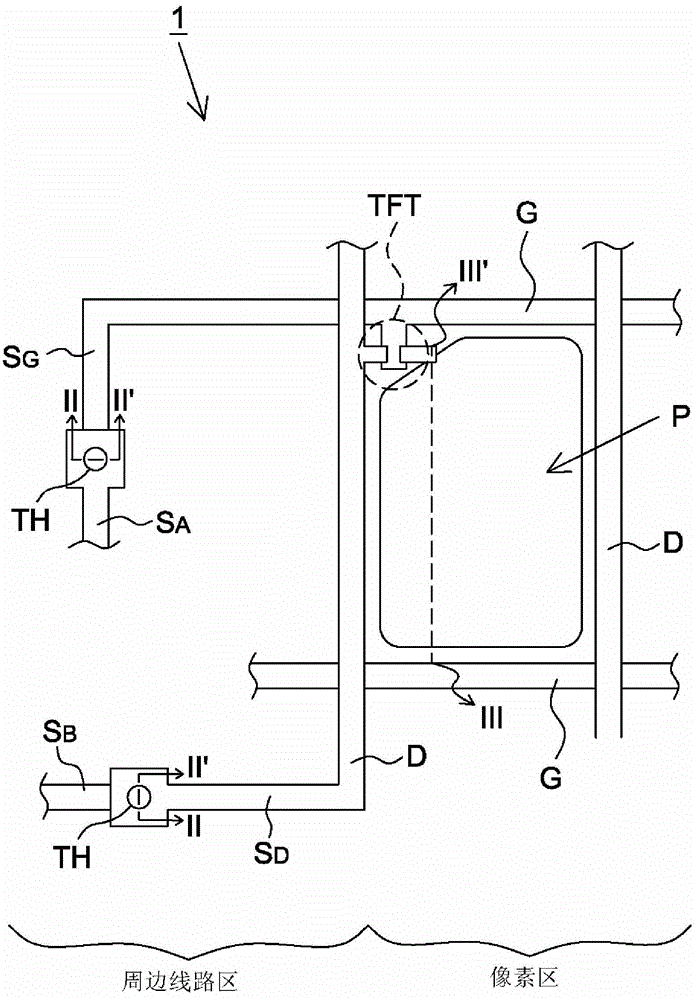

[0052] figure 2 A top view of the thin film transistor substrate 1 according to an embodiment of the present invention is shown. For convenience of description, the thin film transistor substrate 1 can be divided into a pixel area and a peripheral circuit area. In this embodiment, the pixel area includes at least a plurality of pixels and signal lines (such as gate lines and data lines) adjacent to the pixels; the peripheral circuit area can be an area other than the pixel area, for example including Components and lines such as gate drivers. In other embodiments, the pixel area may be called an active area or a visible area and the peripheral circuit area may be called an invalid area or an invisible area.

[0053] figure 2In , only the pixel P in the pixel area, the thin film transistor TFT, and the gate line G and the data line D adjacent to the pixel P are shown exemplarily. In fact, the pixel area may include a plurality of pixels and a plurality of thin film transis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com