Preparation method of metal gate

A metal gate and metal filling technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as over-polishing, different grinding rates, and butterfly-shaped depressions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

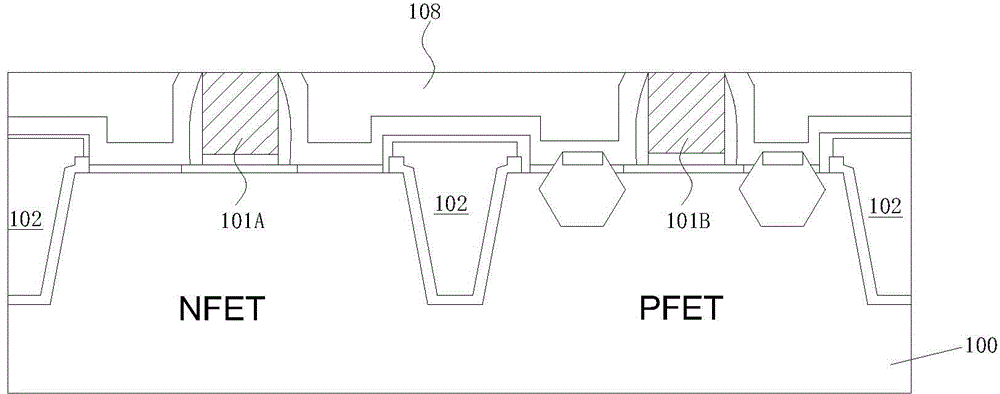

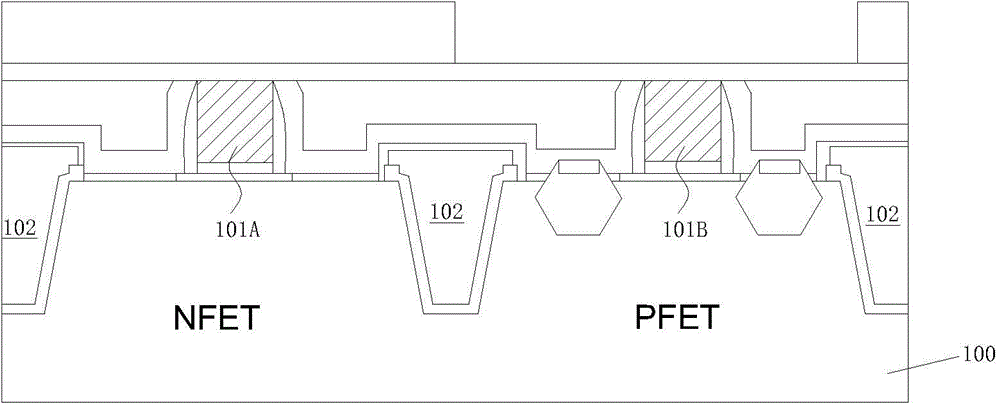

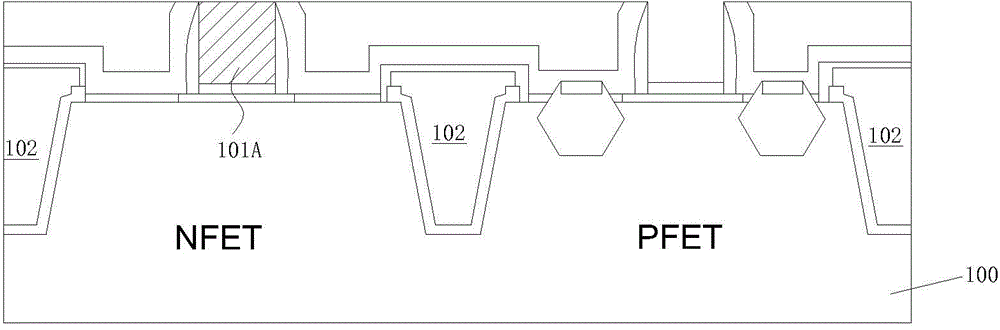

[0033] A method for preparing a metal grid, referring to Figures 3a-3e shown, including the following steps:

[0034] Step S1, providing a substrate, the surface of the substrate is covered with a dielectric layer (not shown in the figure), a first gate groove and a second gate groove are formed in the dielectric layer, and a first sample gate 101A is arranged in the first gate groove , the second sample grid 101B is disposed in the second grid groove; the height of the first sample grid is smaller than the thickness of the dielectric layer, and the height of the second sample grid is equal to the thickness of the dielectric layer.

[0035] Wherein, an N-MOSFET region (such as P-well) and a P-MOSFET region (such as N-well) are arranged in the substrate, and the N-MOSFET region and the P-MOSFET region are separated by a shallow trench isolation structure. isolation. The shallow trench isolation structure is that the trench is filled with an insulating material such as oxide,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com