Micro needle transdermal patch for treating osteoarthritis and preparation method thereof

A technology for transdermal drug delivery and osteoarthritis, applied in the field of traditional Chinese medicine, can solve the problems of small drug storage and short sustained release time, and achieve the effects of prolonging drug efficacy, avoiding repeated administration, and improving drug loading efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

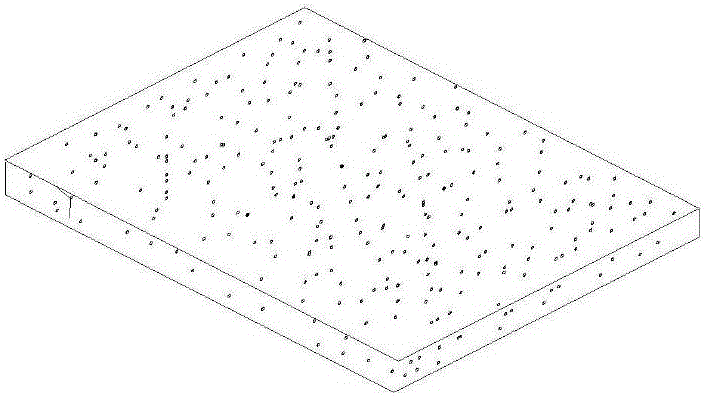

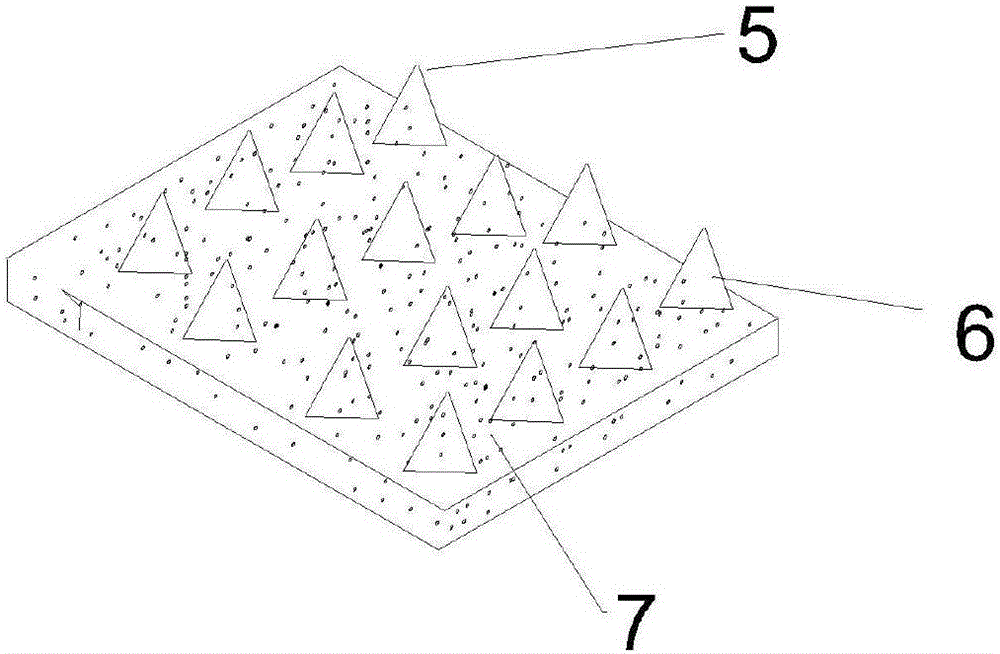

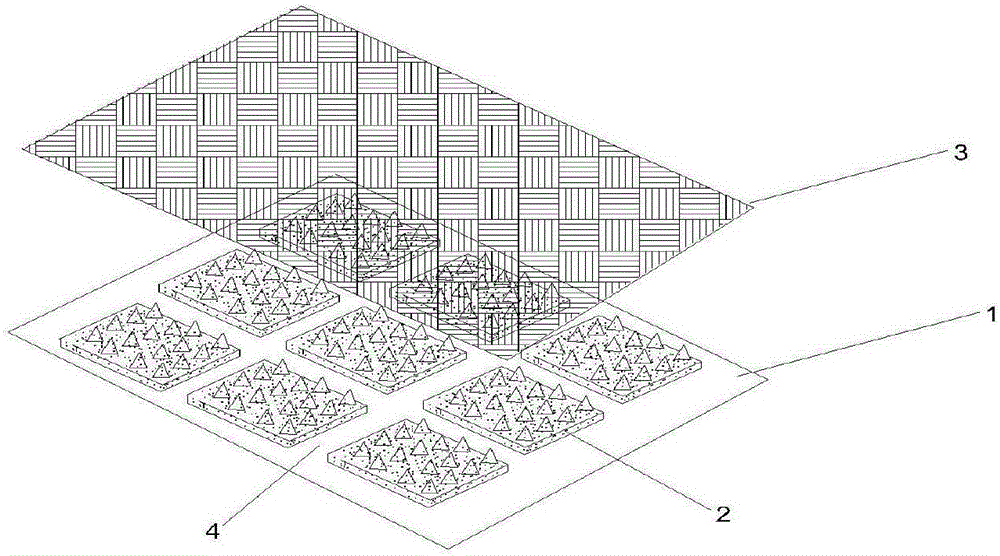

[0026] Such as Figure 1~4 As shown, the substrate 2 is located in the middle of the ointment blank paste and the ointment back paste, and the front side of the substrate forms many microneedles 6 on its surface after laser-etching, and these microneedles 6 form a group of rectangular microneedles on the substrate 2 array. The substrate 2 is made of a porous silicon material with a porous structure. The tip of the microneedle 6 is provided with a spike 5, and the microneedle 6 is vertically fixed on the substrate 2. There is a microneedle gap 7 between the microneedles 6, and the medicine is stored in the microneedle. Among the gap 7 and the porous structure, the back side of the substrate 2 is a plane, and the back side of the substrate 2 is pasted on the inner surface 1 of the ointment blank sticker, and the inner surface of the ointment back sticker 3 is covered on the front surface of the substrate 2, and the inner surface of the ointment blank sticker The surface 1 and t...

Embodiment 2

[0028] In this embodiment, the material used for the substrate 2 is porous polystyrene, and the substrate 2 has a porous structure. After the front of the substrate undergoes laser-etching, many microneedles 6 are formed on the surface, and these microneedles 6 are formed on the substrate 2. A group of rectangular microneedle arrays. The microneedle array is formed by arranging a plurality of microneedles 6 in order. The tip of the microneedles 6 is provided with a spiked portion 5. The microneedle array is vertically fixed on the substrate 2. Between the microneedles 6 There is a microneedle gap 7 between them, and the medicine is stored in the microneedle gap 7 and the porous structure. The back side of the substrate 2 is flat, and the back side of the substrate 2 is pasted on the inner surface 1 of the ointment blank sticker, and the ointment back sticker 3 covers the inner surface of the substrate 2. On the front side, the size and shape of the inner surface 1 of the ointme...

Embodiment 3

[0030]In Embodiment 3, the material used for the substrate 2 is a porous titanium material, and the substrate 2 has a porous structure. The front of the substrate 2 is provided with a microneedle array, and the microneedle array is formed by a plurality of microneedles 6 arranged in sequence. There are spikes 5 at the top of the blade, and the size of the spikes 5 can be adjusted according to the actual needs of laser-etching precision. The microneedle array is vertically fixed on the substrate 2, and there are microneedle gaps 7 between the microneedles 6. Stored in the microneedle gap 7 and the porous structure, the back of the substrate 2 is flat, the back of the substrate 2 is pasted on the inner surface 1 of the ointment blank sticker, the inner surface of the ointment back sticker 3 is covered on the front of the substrate 2, and the ointment The inner surface 1 of the blank sticker and the inner surface of the ointment back sticker are fixedly connected by pasting. There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com