Preparation method for hemp-fiber non-woven multilayer composite gradient filtering material

A technology of non-woven fabric and filter material, which is applied in the field of preparation of multi-layer composite gradient filter material of hemp fiber non-woven fabric, can solve problems such as the reduction of single-fiber filtration efficiency, and achieves broad market application prospects, small pore size, and good filtration. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] Example 1

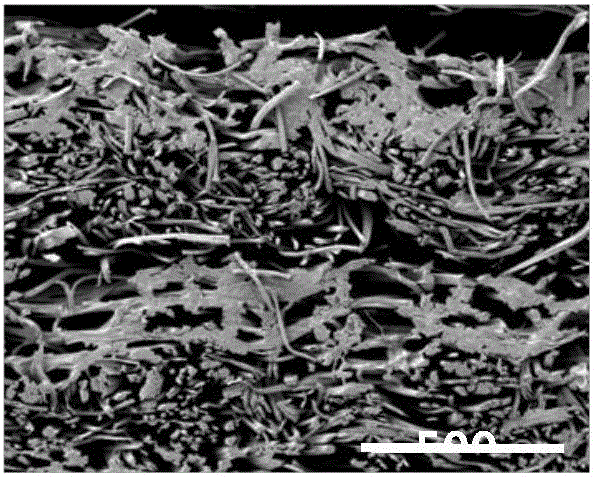

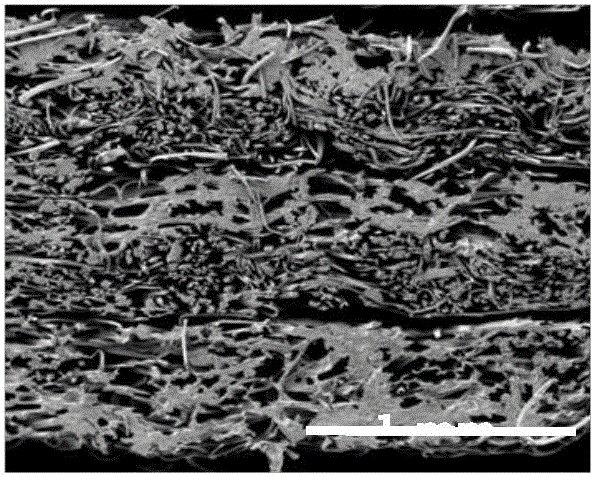

[0026] The preparation method of the hemp fiber nonwoven multi-layer composite gradient filter material of this embodiment includes the following steps: 1) Select hemp / viscose spunlace nonwoven fabric as the substrate. 2) Take 1 piece of substrate from step 1), pour the acrylic adhesive into the dipping tank, then immerse one side of the substrate in the acrylic adhesive for 4 s, and then immerse the other side of the substrate in acrylic 4s in the adhesive. Use a set of rollers to remove the excess acrylic adhesive from the hemp / viscose spunlace nonwoven fabric and make the acrylic adhesive evenly distributed, as the hemp / viscose spunlace nonwoven fabric impregnated with acrylic adhesive for standby. 3) Take another piece of hemp / viscose spunlace nonwoven fabric substrate, directly cover the hemp / viscose spunlace nonwoven fabric impregnated with acrylic adhesive on the substrate, and laminate it with a pressing roller. Dry the prepared laminated composite ma...

Example Embodiment

[0027] Example 2

[0028] The preparation method of a hemp fiber nonwoven multi-layer composite gradient filter material of this embodiment includes the following steps: 1) Select hemp / viscose spunlace nonwoven as a substrate. 2) Take 2 substrates from step 1), pour the acrylic adhesive into the dipping tank, then immerse one side of the substrate in the acrylic adhesive for 4 s, and then immerse the other side of the substrate in the dipping tank. 4s in acrylic adhesive. Use a set of rollers to remove excess acrylic adhesive on the hemp / viscose spunlace nonwoven fabric and make the acrylic adhesive evenly distributed. Then take another piece of the same substrate, pour the acrylic adhesive into the dipping tank, then immerse one side of the substrate in the acrylic adhesive for 4 s, and then immerse the other side of the substrate in the acrylic adhesive 4s. Use a set of rollers to remove excess acrylic adhesive on the hemp / viscose spunlace nonwoven fabric and make the acryli...

Example Embodiment

[0029] Example 3

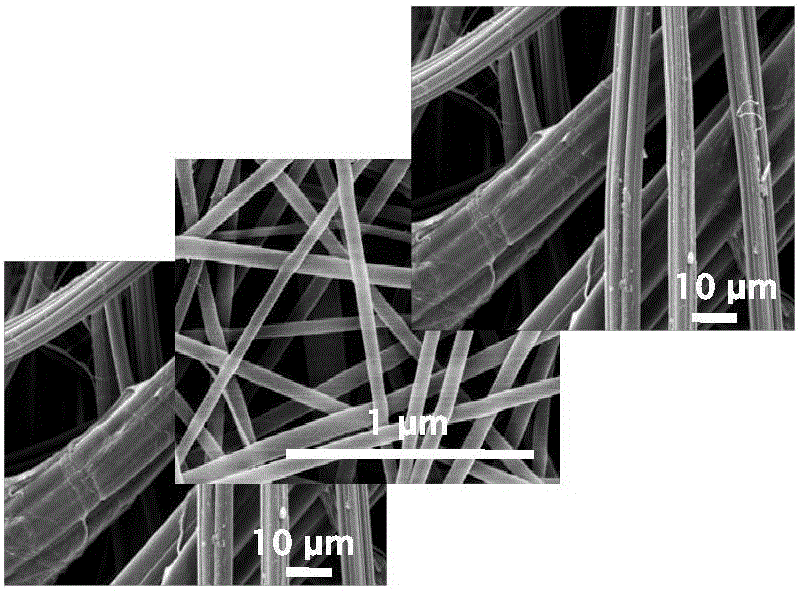

[0030] The preparation method of a hemp fiber nonwoven multi-layer composite gradient filter material of this embodiment includes the following steps: 1) Select hemp / viscose spunlace nonwoven as a substrate. 2) Take 2 substrates of step 1), one of which is prepared by using 22% spinning solution to prepare an electrospun PA6 nanofiber layer on the substrate, and then take a piece of the same substrate, and pour the acrylic adhesive on the substrate. Then immerse one side of the substrate in the acrylic adhesive for 4 s, and then immerse the other side of the substrate in the acrylic adhesive for 4 s. Use a set of rollers to remove the excess acrylic adhesive on the hemp / viscose spunlace non-woven fabric and make the acrylic adhesive evenly distributed for use. 3) Take another hemp / viscose spunlace nonwoven fabric substrate, and directly cover the hemp / viscose spunlace nonwoven fabric impregnated with acrylic adhesive and electrospun PA6 nanofiber layer on the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap