Tool and manufacturing method thereof

A tool and tool body technology, applied in the field of tool and its preparation, can solve the problems of complex forming process, high production cost, long production time, etc., and achieve the effect of simple forming process, low processing cost and small surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

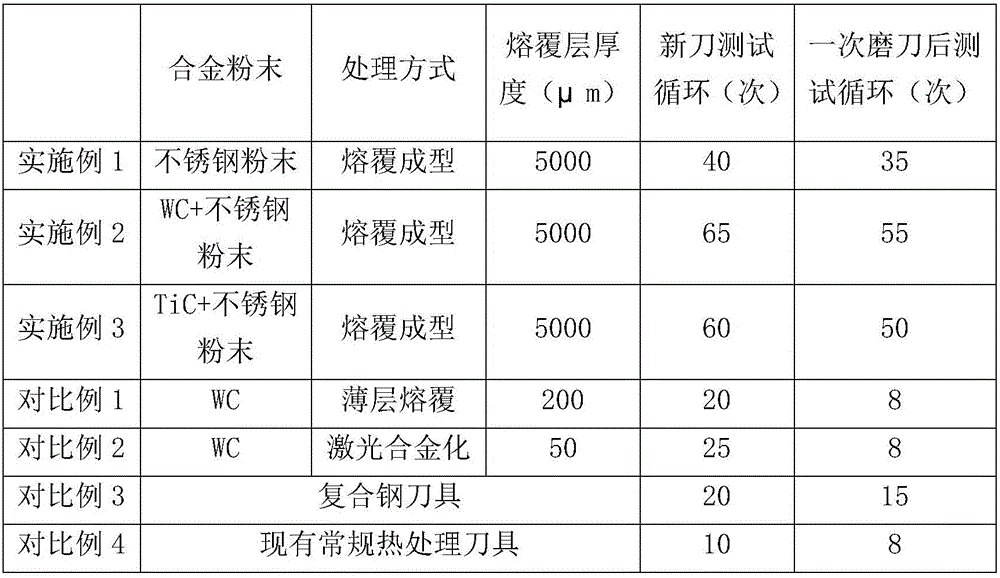

Examples

preparation example Construction

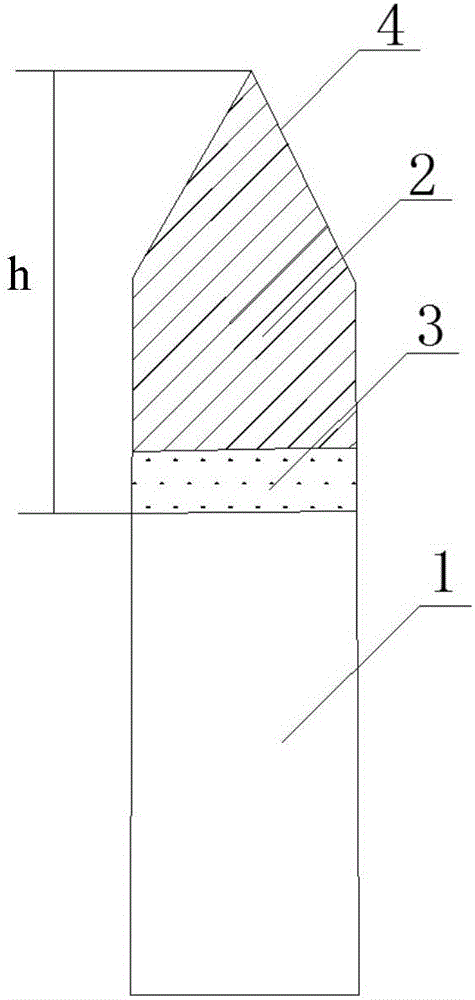

[0029] The preparation method of the cutting tool of the present invention will be described in detail below.

[0030] The cutting tool of the present invention mainly comprises the following steps:

[0031] 1) Stamping and forming the first cutter body part 1, and heat treatment:

[0032] The first cutter body part 1 is stamped and formed by a conventional stamping process. Then, heat treatment is performed on the first cutter body part 1. The heat treatment process is as follows: firstly, at a quenching temperature of 1050°C-1080°C, heating for 50-60 minutes, then cooling for 70 minutes, and then tempering at a tempering temperature of 150°C At -220°C, keep warm for 2-3 hours, and heat treatment can effectively improve the hardness and wear resistance of the first cutter body, making its hardness reach 52-55HRC.

[0033] 2) Laser cladding forming the second cutter body part 2:

[0034] The second cutter body 2 with a three-dimensional structure is directly formed from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com