Defect mending method for martensite heat-resistant steel threaded hole

A defect repair and threaded hole technology, applied in the field of threaded hole defect repair of steel castings, can solve problems such as inapplicability of preheating welding methods, workpiece deformation, and impact on dimensional accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the embodiments. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. Ordinary technicians can also obtain other drawings based on these drawings on the premise of not paying creative work.

[0019] An embodiment of the present invention provides a method for repairing defects in threaded holes of martensitic heat-resistant steel, comprising the following steps:

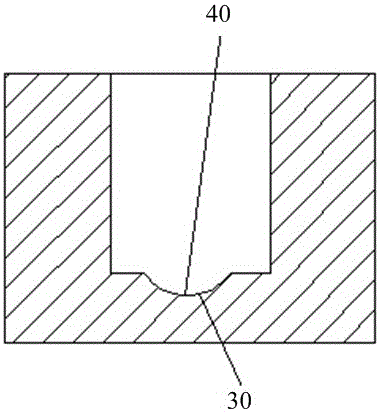

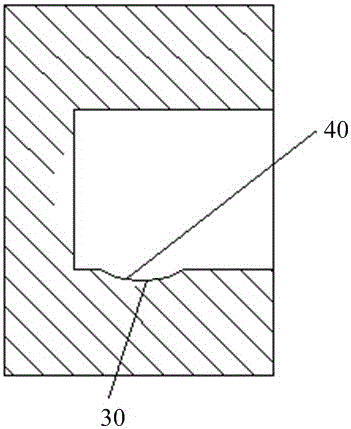

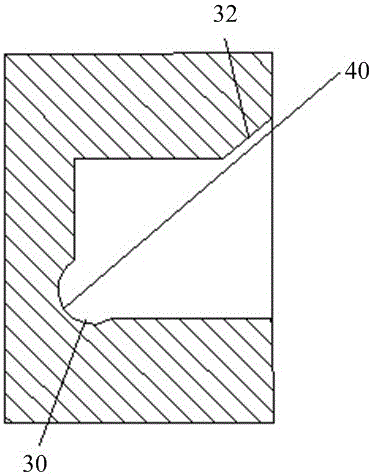

[0020] Excavation of defects: use electric tools to grind the defects in the threaded holes to excavate the defects to form welding repair parts 30, and then perform PT inspection on the defect excavation parts. Among them, because it is martensitic steel, electric tools are used to remove defects, instead of pneumatic grinding tools. Because the heat of the gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com