Forming method of iron-based superalloy shunt ring

A technology of iron-based superalloy and forming method, which is applied in the processing field of high temperature and high pressure and high gas shunt ring of solid rocket attitude control power system, can solve the problems of uneven wall thickness of outer wall, inability to realize pipe penetration technology, etc., and achieve the quality of forming appearance. Good, strong bearing capacity and uniform wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

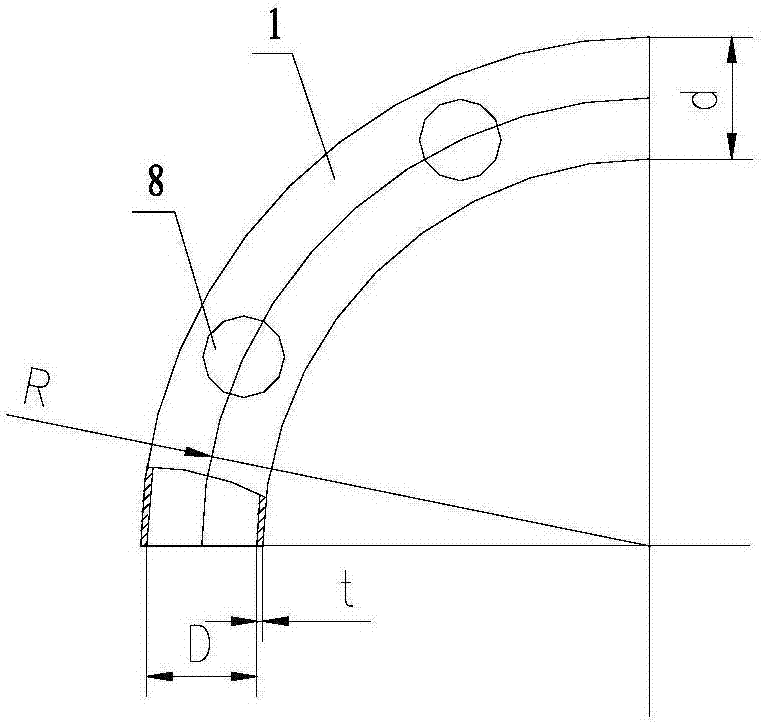

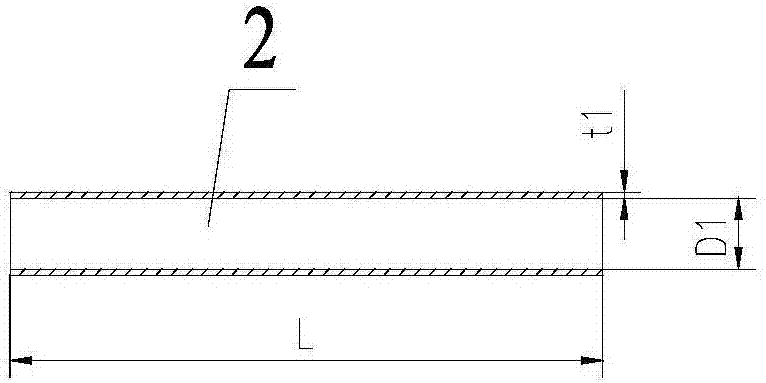

[0043] For a certain type of solid engine attitude control system iron-based superalloy shunt ring, the center radius R of the shunt ring is 205mm, the inner diameter D = 40mm, the wall thickness t = 1.5mm, and the outer diameter d = 43mm; the forming of the iron-based superalloy shunt ring The method includes the following steps:

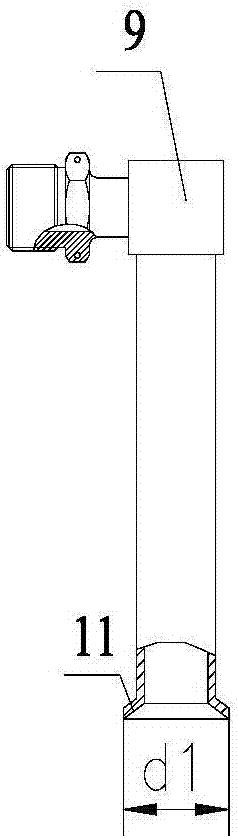

[0044] 1) Divide the iron-based superalloy shunt ring into four equal parts to form four shunt ring units 10, each shunt ring unit includes a circular arc-shaped pipe 1 and a shunt joint 9, that is, the central radius R of the circular arc-shaped pipe is 205mm, Inner diameter D=40mm, wall thickness t=1.5mm, outer diameter d=43mm, such as figure 1 shown.

[0045] 2) The circular arc-shaped pipe 1 and the shunt joint 9 are processed. The annular arc-shaped pipe 1 is provided with a mounting hole 8 which is welded to the shunt joint 9. The diameter of the mounting hole 8 is D. 2 = 0.6 × d; and a finishing allowance of 3 mm is left on the butt weldin...

Embodiment 2

[0061] For a certain type of solid engine attitude control system iron-based superalloy shunt ring, the center radius R of the shunt ring is 205mm, the inner diameter D = 40mm, the wall thickness t = 1.5mm, and the outer diameter d = 43mm; the forming of the iron-based superalloy shunt ring The method includes the following steps:

[0062] 1) Divide the iron-based superalloy shunt ring into three equal parts to form three shunt ring units, each shunt ring unit includes a circular arc tube and a shunt joint, that is, the central radius R of the circular arc tube is 205mm, and the inner diameter D = 40mm, wall thickness t=1.5mm, outer diameter d=43mm.

[0063] 2) Process the circular arc-shaped pipe and the shunt joint. The circular arc-shaped pipe is provided with a mounting hole for butt welding with the shunt joint. The diameter of the mounting hole is D. 2 = 0.8 × d; and a finishing allowance of 5 mm is left on the butt welding end faces of the two ends of the circular arc-...

Embodiment 3

[0079] For the iron-based superalloy shunt ring of a certain type of solid engine attitude control system, the center radius R of the shunt ring is 220mm, the inner diameter D=54mm, the wall thickness t=3mm, and the outer diameter d=60mm; the forming method of the iron-based superalloy shunt ring Including the following steps:

[0080] 1) Divide the iron-based superalloy shunt ring into four equal parts to form four shunt ring units, each shunt ring unit includes a circular arc tube and a split joint, that is, the central radius R of the circular arc tube is 220 mm, and the inner diameter D = 54mm, wall thickness t=3mm, outer diameter d=60mm.

[0081] 2) Process the circular arc tube and the shunt joint. The circular arc tube has a mounting hole welded with the shunt joint. The diameter of the mounting hole is D 2 = 0.7×d; and there is a finishing allowance of 4 mm on the butt welding end faces of the circular arc tubes, the wall thickness t error of the circular arc tubes is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com