Three-axis-linkage automatic sand blasting device for diamond wire polycrystalline silicon slices

A technology for polycrystalline silicon wafers and sandblasting devices, which is used in fine working devices, metal processing equipment, grinding machines, etc., can solve the problems of high equipment cost, environmental pollution, and inability to use industrial production, and achieve uniform processing quality and no environmental pollution. , the effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The description of the exemplary embodiments is for the purpose of illustration only, and in no way limits the invention and its application or usage.

[0041] The surface of the polycrystalline silicon wafer cut by diamond wire is too smooth. In order to solve the problem that the surface of the polycrystalline silicon wafer cut by diamond wire is too smooth, the present invention performs sandblasting treatment on the surface of the polycrystalline silicon wafer cut by diamond wire. The roughness of the surface of the diamond wire polysilicon wafer is improved by sandblasting, so that it can be directly used to make solar cells.

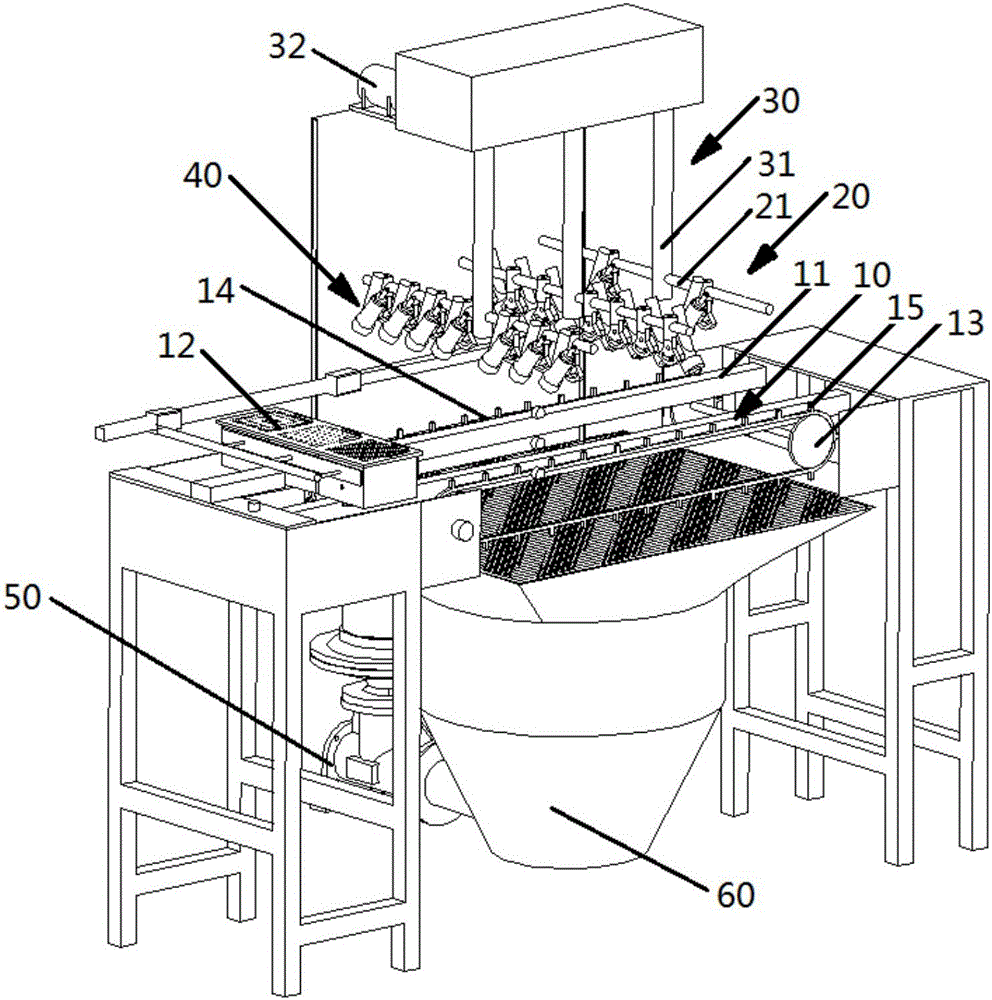

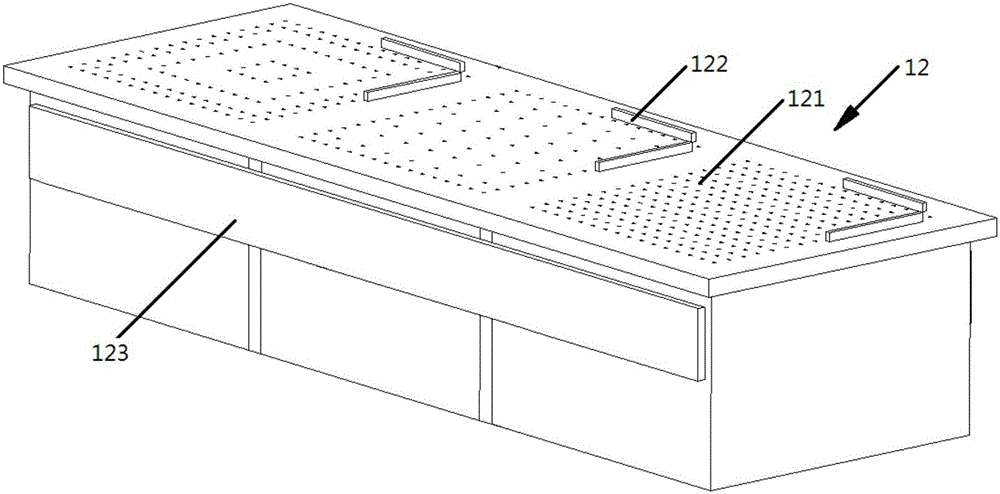

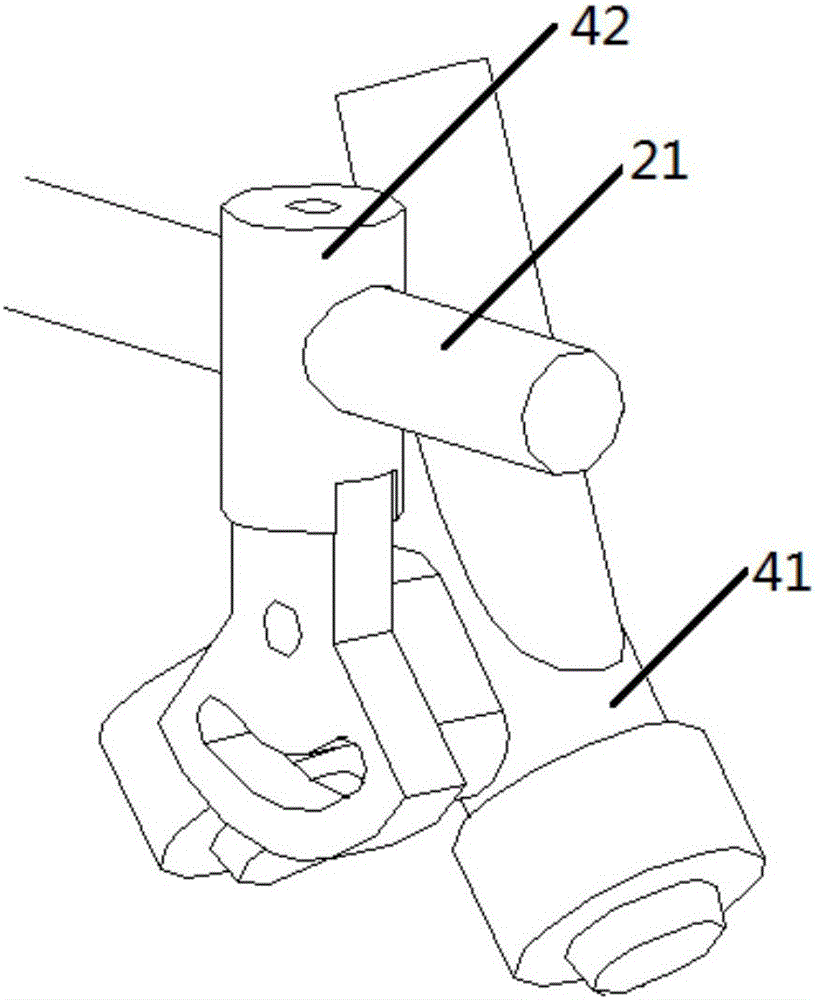

[0042] see figure 1 According to the present invention, the three-axis linkage automatic sandblasting device for diamond wire polysilicon wafers comprises: a vertical transmission mechanism 10, a horizontal transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com