Black aluminum plastic film and polymer lithium battery

An aluminum-plastic film, black technology, applied in the direction of secondary batteries, battery pack parts, battery boxes/covers, etc., can solve problems such as poor slipperiness, increased manufacturing costs, and poor slippery properties of aluminum-plastic films. Achieve the effects of enhancing chemical resistance, prolonging service life, and good chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

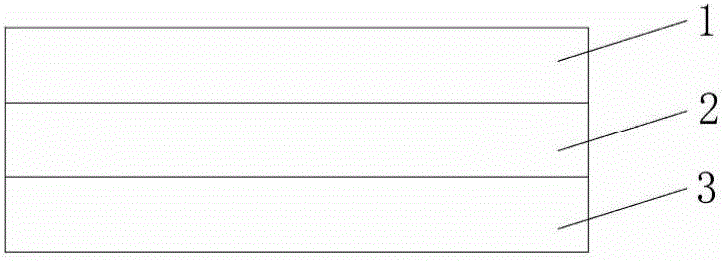

[0040] The black aluminum-plastic film of the embodiment of the present invention, as figure 1 As shown, from top to bottom, the structure of each layer is as follows:

[0041] layer Material first floor 1 Black cast polypropylene film layer second layer 2 Aluminum foil layer third floor 3 transparent polyamide fiber layer

[0042] Wherein, the cast polypropylene film layer is a black layer, and the polyamide fiber layer is a transparent layer.

[0043] The black cast polypropylene film layer is a black layer made by mixing and casting the cast polypropylene film and black masterbatch, and the cast polypropylene film layer and the polyamide fiber layer are coated on both sides of the aluminum foil layer respectively.

[0044] The advantages of the black aluminum-plastic film in the embodiment of the present invention are mainly reflected in the following three aspects: first, the introduced black layer contains carbon black, so that the al...

Embodiment 2

[0047] The black aluminum-plastic film of the embodiment of the present invention, as figure 1 As shown, from top to bottom, the structure of each layer is as follows:

[0048] layer Material first floor 1 Transparent cast polypropylene film layer second layer 2 Aluminum foil layer third floor 3 black polyamide layer

[0049] Wherein, the polyamide fiber layer is a black layer, and the casting polypropylene film layer is a transparent layer.

[0050] The black polyamide fiber layer is a black layer made by mixing and casting polyamide fiber and black masterbatch, and the cast polypropylene film layer and the polyamide fiber layer are coated on both sides of the aluminum foil layer respectively.

[0051] The black aluminum-plastic film of the embodiment of the present invention has better smoothness, better chemical resistance, better character prominence and character color variability.

[0052] In addition, the cast polypropylene film la...

Embodiment 3

[0054] The black aluminum-plastic film of the embodiment of the present invention, as figure 1 As shown, from top to bottom, the structure of each layer is as follows:

[0055] layer Material first floor 1 Black cast polypropylene film layer second layer 2 Aluminum foil layer third floor 3 black polyamide layer

[0056] Wherein, the cast polypropylene film layer and the polyamide fiber layer are both black layers.

[0057] The black cast polypropylene film layer is a black layer made by mixing and casting cast polypropylene film and black masterbatch, and the black polyamide fiber layer is a black layer made by mixing and casting polyamide fiber and black masterbatch Layer, cast polypropylene film layer and polyamide fiber layer are coated on both sides of the aluminum foil layer respectively.

[0058] The black aluminum-plastic film of the embodiment of the present invention has better smoothness, better chemical resistance, better chara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com