Mg-Nb doped bismuth titanate microwave dielectric ceramic and preparation method thereof

A technology of microwave dielectric ceramics and bismuth titanate, which is applied in the field of microwave dielectric ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

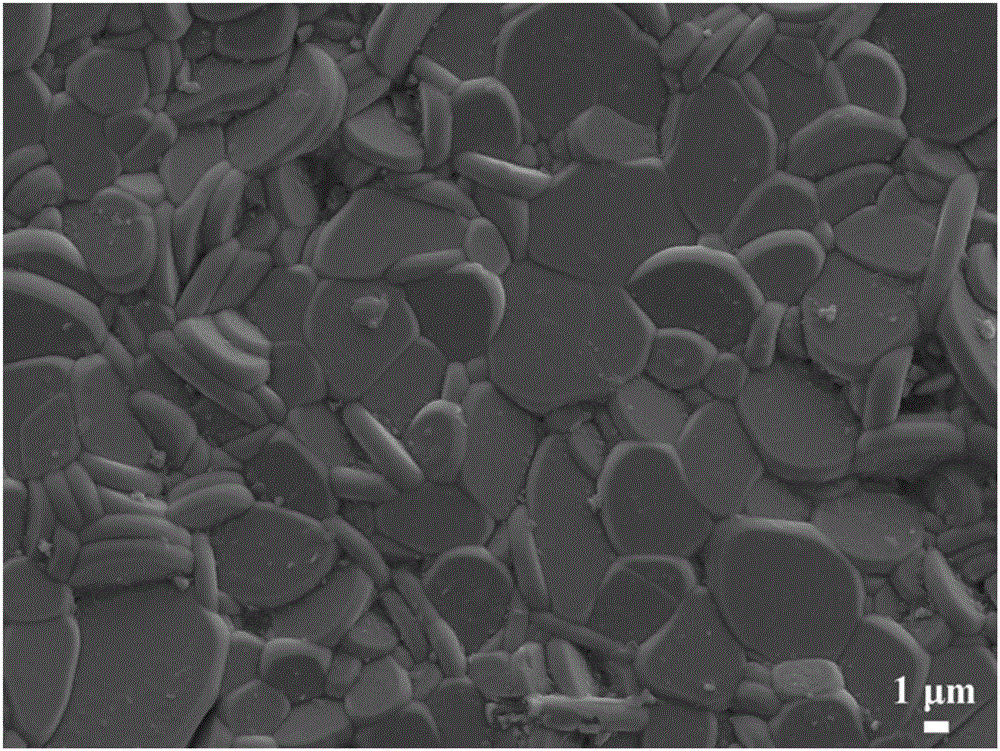

Image

Examples

Embodiment Construction

[0029] Raw material Bi used in the present invention 2 o 3 , TiO 2 ,(MgCO 3 ) 4 ·Mg(OH) 2 ·5H 2 O and Nb 2 o 5 All are commercially available chemically pure raw materials (mass purity ≥ 99%). The microwave dielectric ceramic material with good comprehensive properties is prepared by the traditional method, that is, the solid-state reaction mixing method and sintering at atmospheric pressure.

[0030] The preparation method of the present invention is as follows:

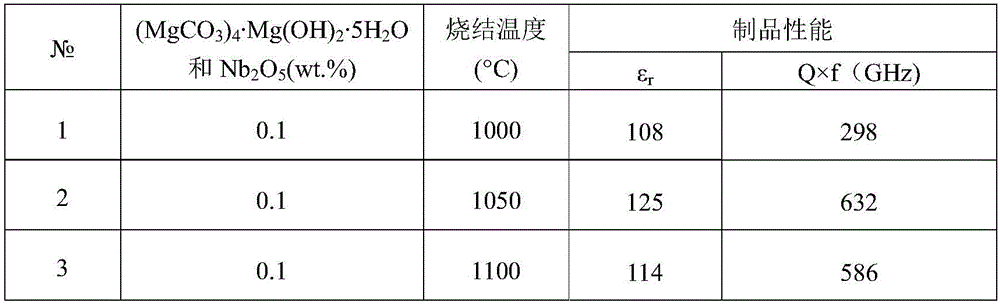

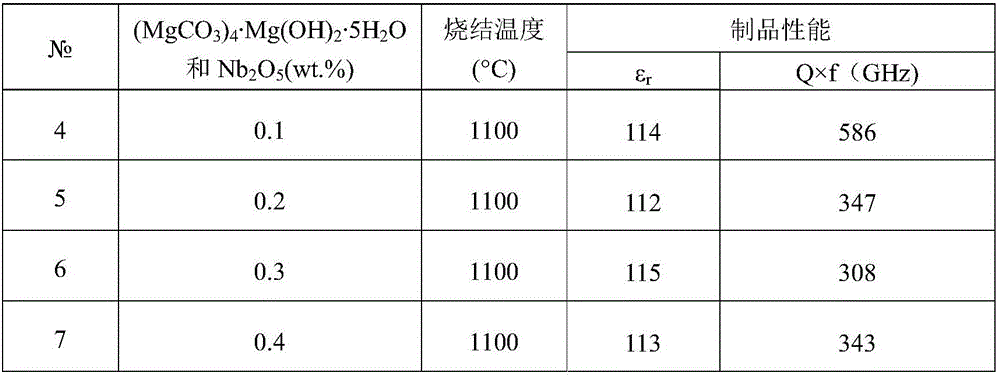

[0031] (1) Ingredients

[0032] Raw material Bi 2 o 3 , TiO 2 ,(MgCO 3 ) 4 ·Mg(OH) 2 ·5H 2 O and Nb 2 o 5 by Mg x Bi 4-x Ti 3-x Nb x o 12 , the stoichiometric ratio of x=0.1~0.4 in the formula, put it into the ball mill tank after mixing, the ball milling medium is deionized water and zirconia balls, the weight ratio of balls:material:deionized water is 2:1:0.6 ; The ball milling time is 6 hours, and the rotating speed of the ball mill is 750 rpm; then the mixture is put into an oven and drie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com