Method for preparing carboxymethyl chitosan film through dialysis and application of carboxymethyl chitosan film

A carboxymethyl chitosan and film technology, applied in the field of carboxymethyl chitosan film and its preparation, can solve problems such as instability, and achieve the effects of low cost, cost saving and simplified procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

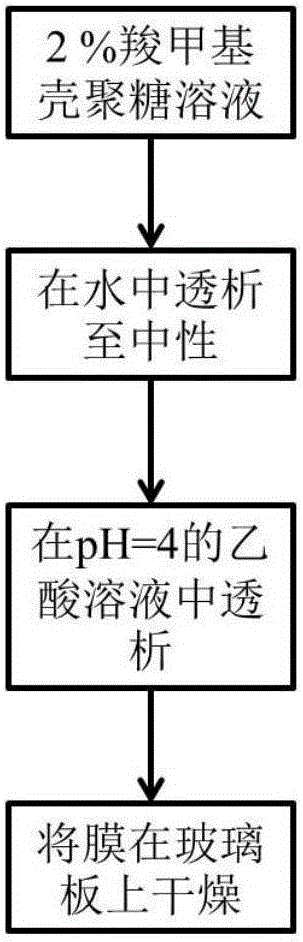

[0045] Such as figure 1 As shown, first put about 2% carboxymethyl chitosan solution into the dialysis bag, put the dialysis bag into clean water for dialysis, dialyze in water until it is about neutral, and then put the dialysis bag into the pH value of about Carboxymethyl chitosan film was obtained by dialysis in acetic acid solution of 4.

[0046] Weigh 0.4g carboxymethyl chitosan and dissolve it in 19.6g water, stir overnight to prepare 2% carboxymethyl chitosan solution. The above solution was centrifuged and degassed. The centrifugation speed is 10000r / min, and the centrifugation time is 5min; the suction filtration vacuum degree used for vacuum degassing is 0.09MPa to 0.1MPa, and the suction filtration time is 30min. After the pretreatment is completed, 15 g of carboxymethyl chitosan solution is weighed and put into a dialysis bag. The dialysis bag has a molecular weight cut-off of 8000-14000 Da and a diameter of 34 mm. Secure the closure with clips. Put the dialysi...

Embodiment 2

[0052] Weigh 0.5g carboxymethyl chitosan and dissolve it in 26.5g water, stir overnight to prepare 2% carboxymethyl chitosan solution. The above solution was centrifuged and degassed. The centrifugation speed is 8000r / min, and the centrifugation time is 10min; the suction filtration vacuum degree used for vacuum degassing is 0.09MPa to 0.1MPa, and the suction filtration time is 60min. After the pretreatment is completed, 15 g of carboxymethyl chitosan solution is weighed and put into a dialysis bag. The dialysis bag has a molecular weight cut-off of 8000-14000 Da and a diameter of 34 mm. Secure the closure with clips. Put the dialysis bag into a 1000mL beaker and dialyze with water for 3 days, changing the water every 3 hours until the pH of the dialysate is close to 7. Put the dialysis bag into 1000 mL of dilute hydrochloric acid solution with a pH of 4.05 to continue dialysis for 36 hours, and a layer of carboxymethyl chitosan film will be slowly deposited on the surface o...

Embodiment 3

[0056] Weigh 0.8g carboxymethyl chitosan and dissolve it in 31.2g water, stir overnight to prepare 2% carboxymethyl chitosan solution. The above solution was centrifuged and degassed. The centrifugation speed is 12000r / min, and the centrifugation time is 5min; the suction filtration vacuum degree used for vacuum degassing is 0.09MPa to 0.1MPa, and the suction filtration time is 20min. After the pretreatment is completed, weigh 30 g of carboxymethyl chitosan solution and put it into a dialysis bag. The molecular weight cut-off of the dialysis bag is 8000-14000 Daltons and the diameter is 34 mm. Secure the closure with clips. Put the dialysis bag into a 2000mL beaker and dialyze with water for 4 days, changing the water every 4 hours until the pH of the dialysate is close to 7. Putting the dialysis bag into 1000 mL of dilute sulfuric acid solution with a pH of 3.95 to continue dialysis for 30 hours, a carboxymethyl chitosan film will slowly deposit on the surface of the dialys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com