Patents

Literature

41results about How to "Peelable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

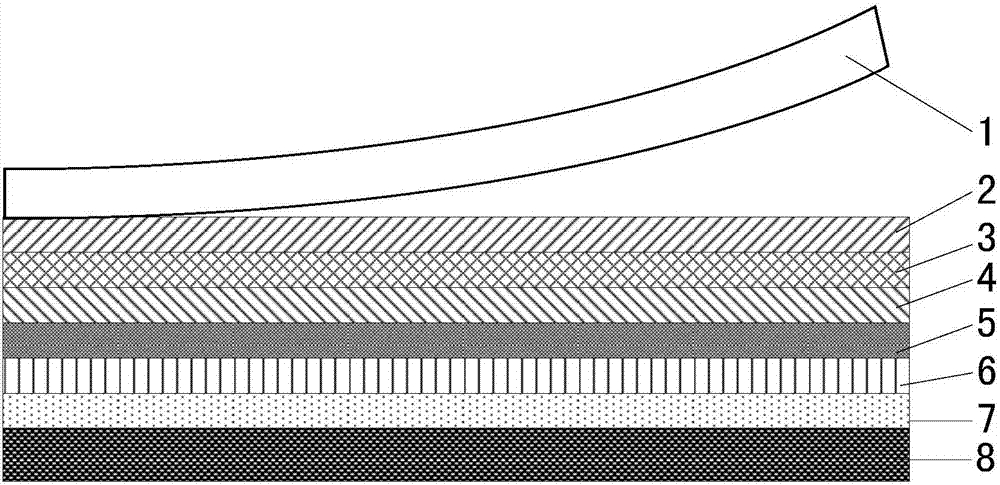

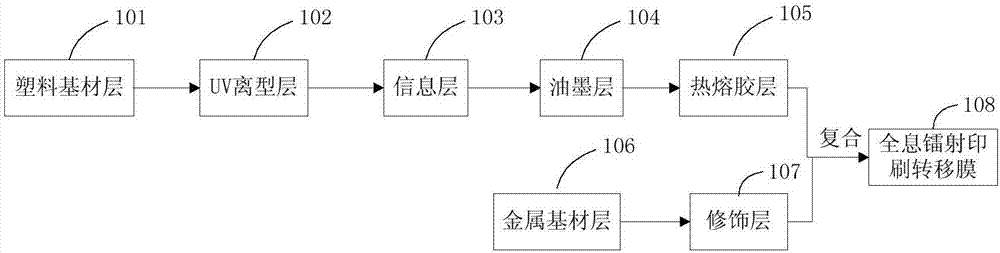

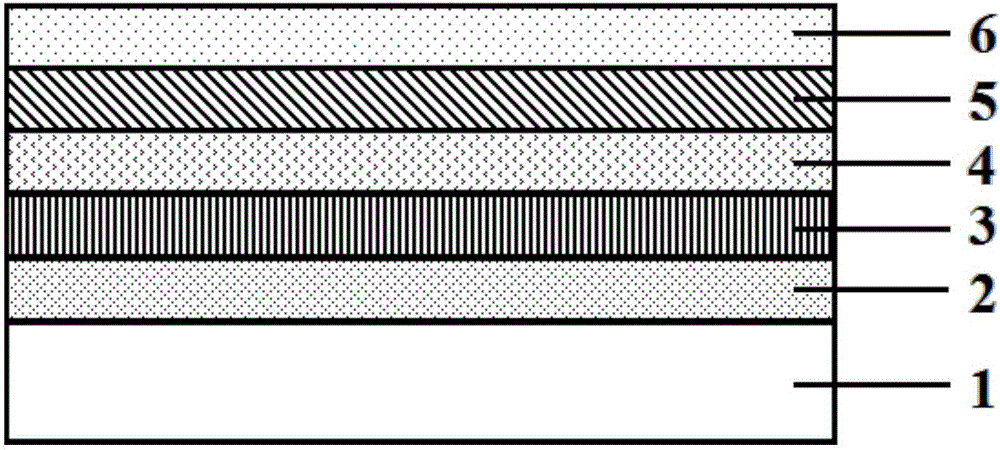

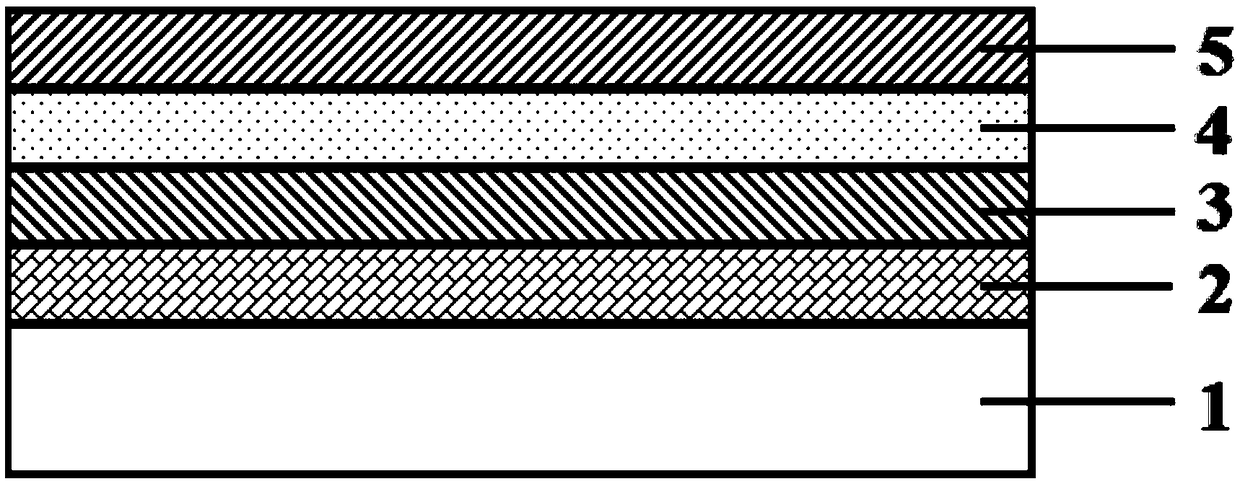

Holographic laser printing transfer film and production process for metal package

The invention discloses a holographic laser printing transfer film and a production process for a metal package. The transfer film comprises a plastic substrate layer, a UV release layer, an information layer, an ink layer, an aluminum reflecting layer, a hot melt adhesive layer and a metal substrate layer which are superposed sequentially. According to the holographic laser printing transfer film of the above structure, the UV release layer, the information layer, the ink layer, the aluminum reflecting layer, the hot melt adhesive layer and the metal substrate layer are combined tightly and mutually and are all high in elongation, and cracks are avoided during composite stripping and punching forming. Compared with existing common metal printing package materials, the holographic laser printing transfer film has a holographic laser anti-counterfeiting function and high visual impact force, meets the requirements of the properties such as impact resistance, surface hardness, stretchability and heat resistance in aftertreatment, and meets the test requirement for the metal package in the subsequent machining procedure. In addition, according to the production process for the metal package, metal printing equipment is omitted, and the cost of a common metal package process is reduced significantly.

Owner:绍兴京华激光材料科技有限公司

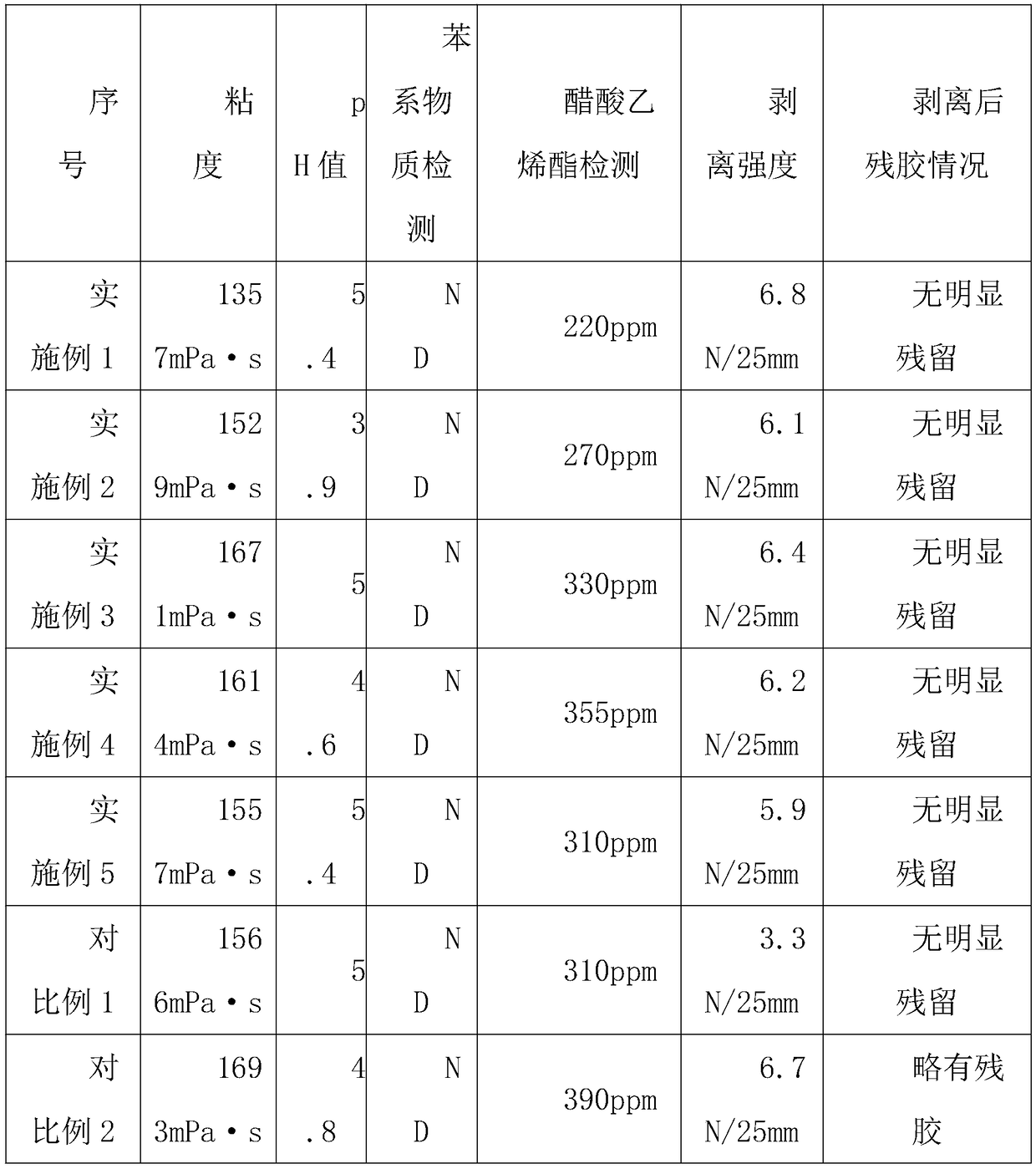

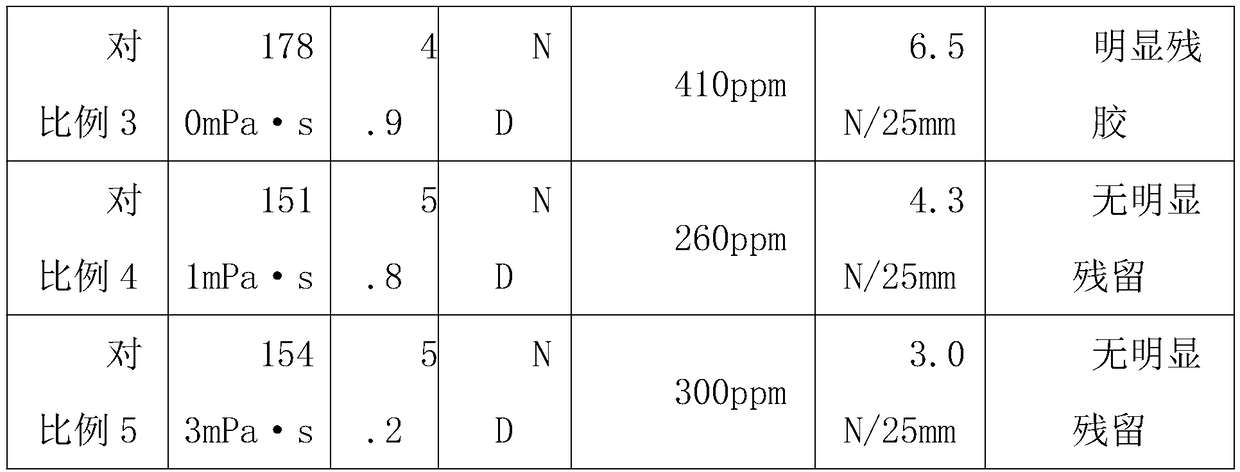

Ultraviolet-curing adhesive and preparation method of same

ActiveCN107502271ASuitable Thixotropic ViscosityReduce hardnessNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterAdhesive

The invention relates to an ultraviolet-curing adhesive and a preparation method of same. The ultraviolet-curing adhesive is composed of, by weight, 20-60 parts of a self-made bifunctional polyurethane-acrylate prepolymer, 5-15 parts of a multifunctional polyurethane-acrylate prepolymer, 5-15 parts of a polyester-acrylate prepolymer, 5-20 parts of a reactive amine compounding agent, 10-30 parts of an acrylate-type activity diluent, 0.5-5% of a flatting and wetting agent, 1-5% of a photoinitiator, 0.5-5 parts of titanium dioxide nano-powder, and 0.1-10 parts of fumed silica. The ultraviolet light curing adhesive is suitable for temporary protection for metal shells, has protective effect during a later-period treatment process of CNC and can be easily stripped-off after the CNC machining. The adhesive has no residue and stripping off on the metal shells.

Owner:YANTAI SEAYU NEW MATERIALS CORP LTD

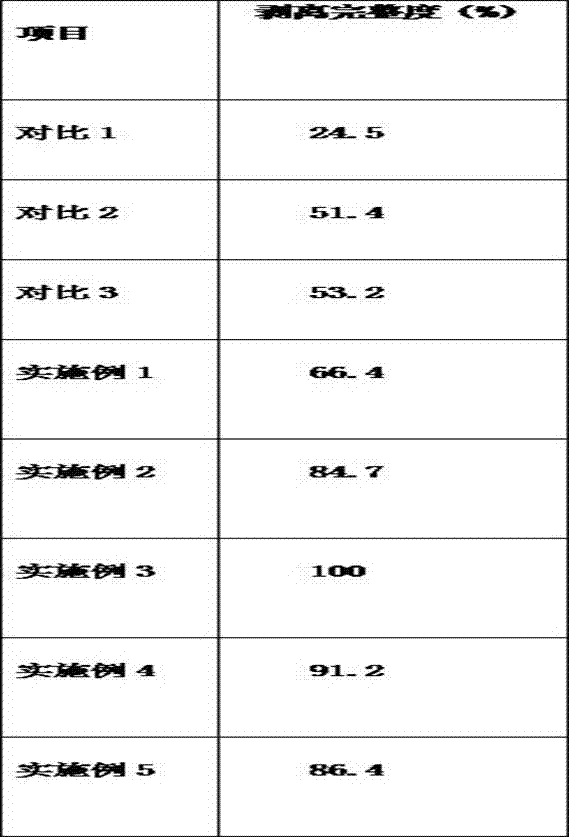

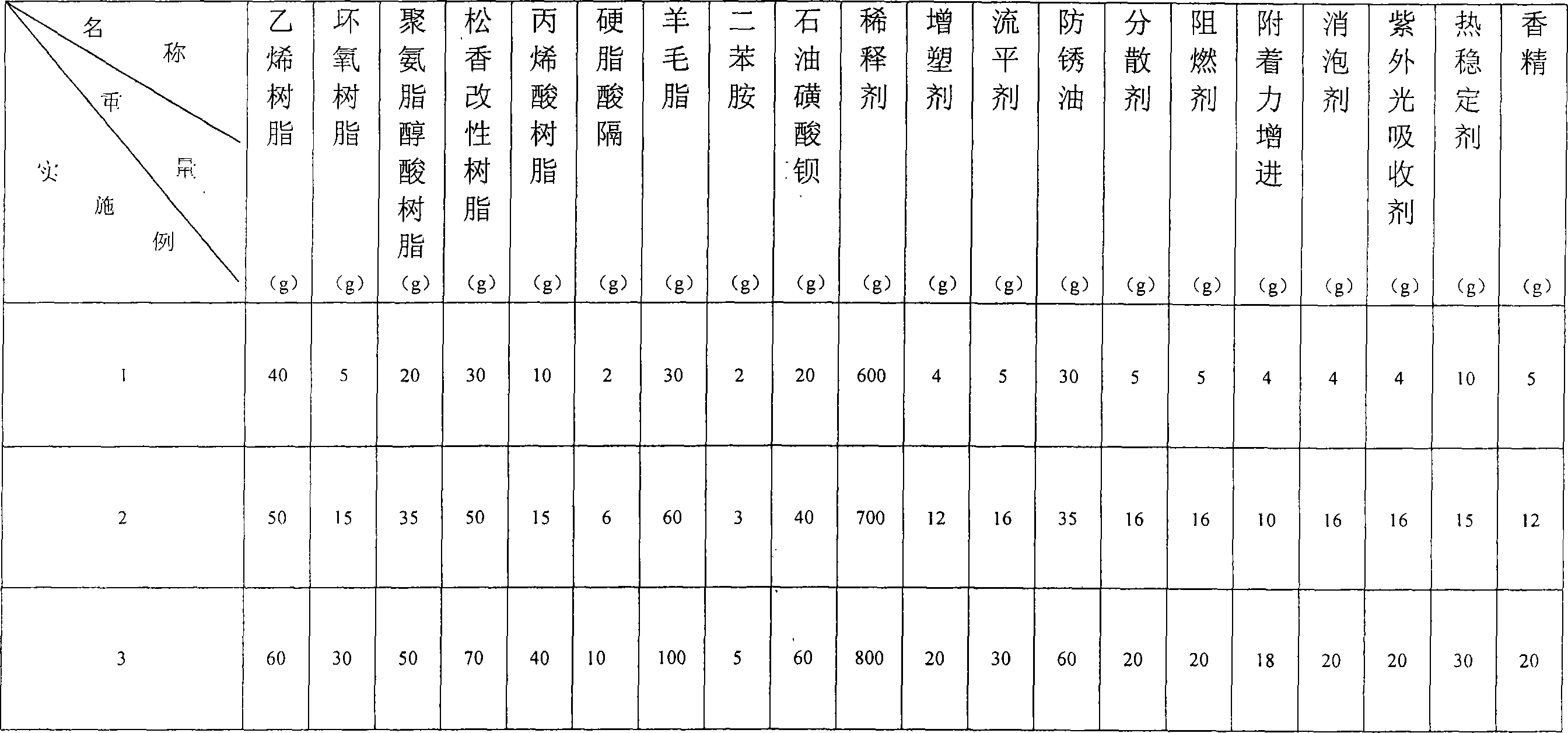

Coating material for high anticorrosive pack, and preparation method

InactiveCN101050329AExcellent physical and chemical propertiesGood chemical resistanceRosin coatingsAnti-corrosive paintsEpoxySolvent

This invention discloses a high-strength antirust packaging paint, which is composed of: ethylene resin, epoxy resin, polyurethane alkyd resin, rosin-modified resin, acrylate resin, cadmium stearate, lanoline, diphenyl amine, barium petroleum sulfonate, essence, antirust oil, plasticizer, heat stabilizer, antirust agent, diluting agent, adhesion promoter, leveling agent, UV absorbent, dispersant, defoamer and flame retardant. The packaging paint can be directly sprayed, soak-coated or brush-coated onto objects with any shape or appearance. A bright and smooth protective film is formed several minutes later. The protective film has high antirust performance, and can be stripped off for recycling.

Owner:郑州博庆环保科技有限公司 +2

Ultraviolet curing adhesive for temporary protection and preparation method of ultraviolet curing adhesive

ActiveCN107474786ASuitable Thixotropic ViscosityReduce hardnessNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterNanowire

The invention relates to an ultraviolet curing adhesive for temporary protection and a preparation method of the ultraviolet curing adhesive. The ultraviolet curing adhesive is prepared from the following raw materials by weight: 20-60 parts of a self-made bifunctional polyurethane acrylate prepolymer, 5-15 parts of a multi-functional polyurethane acrylate prepolymer, 5-15 parts of a polyester acrylate prepolymer, 5-20 parts of a reactive amine compounding agent, 10-30 parts of acrylate type active diluents, 0.5%-5% of a leveling wetting agent, 1%-5% of a photoinitiator, 0.5-5 parts of titanium dioxide nanowires and 0.1-10 parts of fumed silica. The ultraviolet curing adhesive is suitable for temporary protection of a metal casing and plays a protective role in post-processing of CNC, and can be easily peeled off after CNC processing. Residues on the metal casing and falling off of the adhesive are avoided.

Owner:YANTAI SEAYU NEW MATERIALS CORP LTD

Release agent composition for plastic mold and component using the same

InactiveCN1799805AReduce % DefectiveImprove release forceCeramic shaping apparatusLubricant compositionPolymer scienceActive agent

There is provided a novel nonflammable release agent composition for a plastic mold containing: (a) a hydrofluoroether; (b) fluorine oil; and (c) a fluorine-based surfactant, in which the content of the ingredient (a) is 50 wt % or more. The composition is lowly toxic, noncombustible, and more chemically stable than a conventional one, and brings together high persistence of releasability and sufficient durability.

Owner:CANON KK

Application method of ultraviolet curing adhesive for temporary protection

ActiveCN107474787ASuitable Thixotropic ViscosityReduce hardnessAdhesive processesNon-macromolecular adhesive additivesNumerical controlAfter treatment

The invention relates to an application method of an ultraviolet curing adhesive for temporary protection. The adhesive is put in a light-proof needle tube, a needle is mounted, then, the needle tube is put in an automatic dispensing machine, a dispensing procedure is set according to a dispensing route, the air pressure is controlled, the adhesive is injected into screw holes of a metal shell and completely cured under ultraviolet irradiation, the ultrasonic irradiation energy is 600-1,200 mJ / cm<2>, and post-treatment of a CNC (computer numerical control) technology is implemented; ultraviolet irradiation is performed under the ultrasonic irradiation energy of 3,000-6,0 00 mJ / cm<2>after treatment with the CNC technology, and cured adhesive plugs in the screw holes are stripped by hand or ultrasonic waves. The application method is simple to operate, stripping is easy, and residues and falling can be avoided.

Owner:YANTAI SEAYU NEW MATERIALS CORP LTD

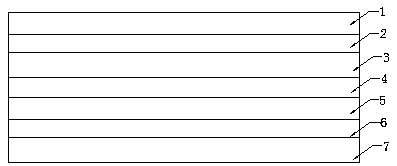

Anti-scrawling heat transfer film for leathers and preparation method thereof

The invention discloses an anti-scrawling heat transfer film for leathers and a preparation method thereof. The anti-scrawling heat transfer film comprises a PET base film; and the PET base film is coated with a release layer, an anti-scrawling layer, a coloring layer, an aluminum plating layer and a back glue layer in sequence, wherein the anti-scrawling layer is formed by mixing and curing silicon auxiliaries and polyurethane resins, can enable scrawled printed objects to recover brightness and tidiness after wiping, has the leather texture and the toughness, and achieves the effect of protecting the coloring layer. The anti-scrawling heat transfer film is excellent in anti-scrawling effect, high in leather texture, excellent in toughness, high in brightness, bright in color and excellent in friction and solvent resistance.

Owner:SUZHOU WONDERFUL NEW MATERIAL CO LTD

Manufacturing method of coating for temporary protection of metal surface

The invention discloses a method for manufacturing a paint for temporary protection on the metal surface, which comprises the following steps: dissolving 30%-40% chloroacetic resin powder with alcohol solvent; dissolving 20% cellulose acetate butyrate with butyl acetate and dimethylbenzene mixed solvent; mixing dissolved chloroacetic resin and cellulose acetate butyrate according to 2:1-3:1; adding 0.5% dimethyl silicon oil; mixing homogeneously; adding deflocculating agent (butyl alcohol:butyl acetate=1:1). The invention is provided with adhesive force and striping property, which avoids the chemical corrosion of the metal.

Owner:TIANJIN ZHENDONG PAINTS CO LTD

High-strength elastic invisible artificial skin

The invention discloses high-strength elastic invisible artificial skin and relates to the field of fine chemistry. The high-strength elastic invisible artificial skin is prepared from a component A and a component B, wherein the component A is prepared from vinyl silicone oil, vinyl modified silicon dioxide particles, a chitosan vinyl derivative and hydrogen-containing silicone oil; the componentB is prepared from a platinum catalyst, silicone oil, a matting agent and a wetting agent. The invention further discloses a production method of the high-strength elastic invisible artificial skin;the preparation method comprises the following steps: preparing the component A, preparing the component B and preparing a coating film. After the component A and the component B are coated, the component A and the component B can be rapidly crossly linked to form the film at room temperature, so that the high-strength elastic coating film is formed and the elasticity of the skin is recovered instantly; the color of the coating film is similar with the color of the skin and the stealthiness is good. The coating film also has a relatively good adhesive force, waterproof performance and scrubbing resistance, and daily washing of the skin is not influenced. In addition, the elastic coating film has relatively high strength and can be peeled from the surface of the skin.

Owner:SHANGHAI QIHONG NEW MATERIAL TECH CO LTD +2

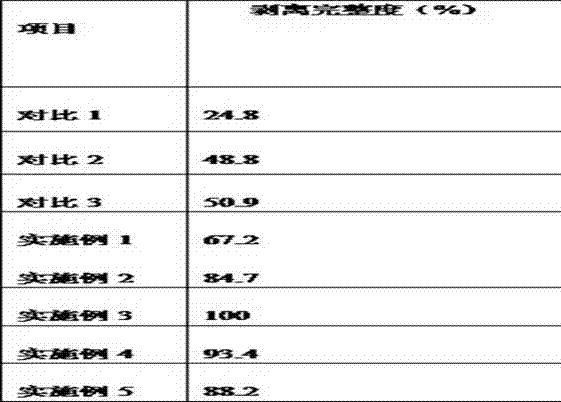

Water-based laser packaging glue used for cigarettes and preparation method thereof

ActiveCN109294488AFast dryingStrong adhesionMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesChemistryCalcium

The invention relates to a water-based laser packaging glue used for cigarettes and a preparation method thereof. The water-based laser packaging glue consists of the following components: a VAE emulsion, nano alumina / crystal alumina, calcium chloride, polyvinyl alcohol, alcohol, a nonionic emulsifier, an environmental protection agent, a preservative, and water. Compared with the prior art, the water-based laser packaging glue has the characteristics of fast drying speed, strong cohesive force, good fluidity, no toxicity, no odor, no corrosion, no burning, and storage resistance. The productquality and various technical performance indicators are superior to similar products, especially in terms of drying speed, bond strength and fluidity, which can be increased by 60% based on the past.The water-based laser packaging glue strictly implements the requirements of the People's Republic of China tobacco industry standard-Volatile and semi-volatile components of tobacco water-based glue, formaldehyde is less than 20ppm, ethyl acetate is less than 400ppm, and the water-based laser packaging glue is inspected by the National Tobacco Quality Supervision and Inspection Center.

Owner:湖北恒阳科技发展有限公司

Nano-silver antibacterial spray-molded protective film and preparation method thereof

InactiveCN111253845AFacilitate strippingEasy to tear offAntifouling/underwater paintsPaints with biocidesAnti bacterialSilver Nano

The invention relates to a nano-silver antibacterial spray-molded protective film. The protective film is characterized by comprising the following components in parts by weight: 20-50 parts of a resin material, 10-20 parts of a nano-silver dispersing agent, 30-60 parts of a solvent, 0-3 parts of a coalescing agent and 0.5-2 parts of a hyperdispersant. The nano-antibacterial spraying agent can protect the surface of an object against scratching, skid and aging, can be easily peeled off, and is high in practicability and wide in application range.

Owner:广东四维新材料有限公司

Creasing and folding resistance hot stamping foil for leather and preparation method thereof

InactiveCN108859564AReduce surface tensionHigh transparencyOrnamental structuresSpecial ornamental structuresHot stampingStamping

The invention discloses creasing and folding resistance hot stamping foil for leather. The creasing and folding resistance hot stamping foil comprises a PET base film; a release layer, a coloring layer, an aluminum plating layer and a back glue layer are coated on the PET base film in sequence; the PET base film is 15-25 microns thick, and achieves low surface tension, high transparency and temperature resistance suitable for the printing industry; the release layer has the characteristic of high-temperature resistance, can protect the coloring layer from being eroded by external environment,and meanwhile, achieves fissility and creasing and folding resistance; the coloring layer achieves temperature resistance, cannot generate the color change and light elimination phenomenon in high-temperature stamping, and meanwhile, is higher in brittleness; the aluminum plating layer can improve the brightness of a heat transfer film to achieve the metal gloss; and the back glue layer is thermoplastic high-elasticity polyurethane, can guarantee firm combination between a color layer and an aluminum layer with the surface of a printed matter, and meanwhile, improves the product toughness, leather feeling and grade. The creasing and folding resistance hot stamping foil is high in leather feeling, higher in brightness, bright in color and excellent in wear resistance and solvent resistance, and can form different patterns on products.

Owner:SUZHOU WONDERFUL NEW MATERIAL CO LTD

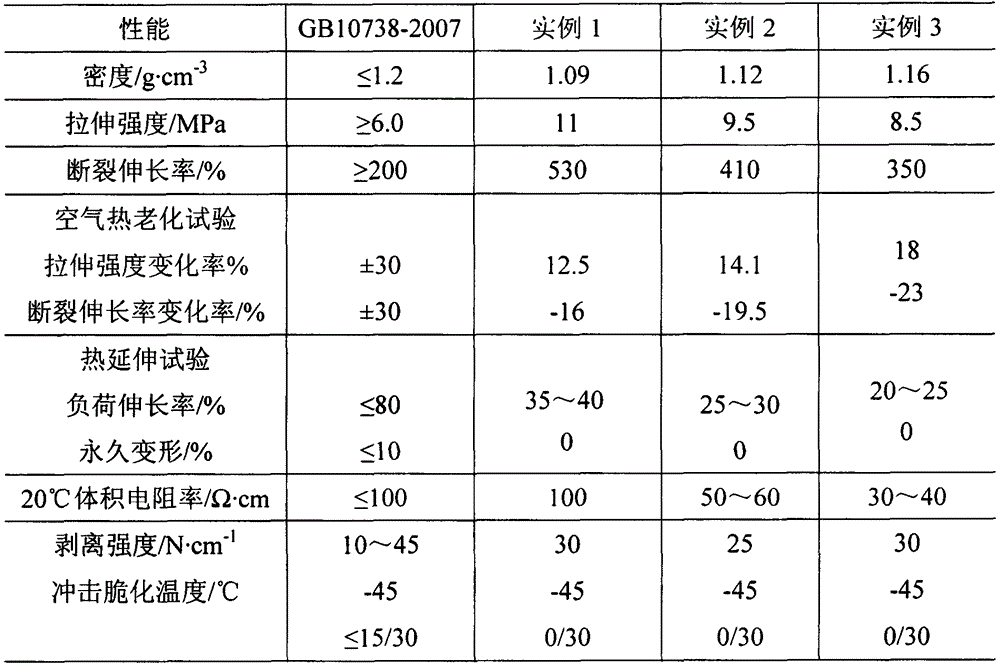

Insulating-layer semiconductive shielding material for ethylene propylene rubber cable

InactiveCN105218894AEvenly dispersedGood dispersionNon-conductive material with dispersed conductive materialStearic acidEthylene propylene rubber

The invention discloses an insulating-layer semiconductive shielding material for an ethylene propylene rubber cable. The material is characterized by being prepared from, by weight, 60-70 parts of nitrile butadiene rubber, 30-40 parts of chlorinated polyethylene, 30-50 parts of cable powder, 50-70 parts of conductive carbon black A, 10-30 parts of conductive carbon black B, 5-10 parts of magnesium oxide, 2-4 parts of paraffin, 2-8 parts of anti-aging agents, 20-30 parts of dioctyl phthalate, 0.5-1 part of dispersants, 2-5 parts of stearic acid and 1-8 parts of vulcanizing agents. The insulating-layer semiconductive shielding material for the ethylene propylene rubber cable has the advantages of good heat oxygen aging resistance, ozone aging resistance, acid-base resistance and chemical resistance performance, excellent oil resistance performance, good removability and glue liquidity, low cost and the like.

Owner:山东太平洋橡缆股份有限公司

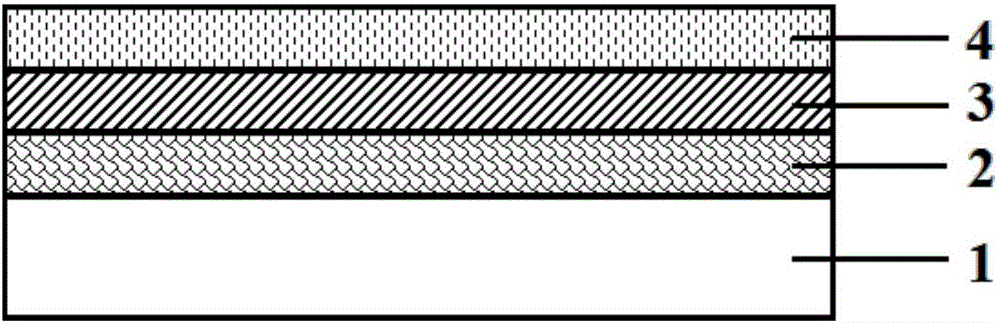

Hot water-resistant biaxially oriented polypropylene (BOPP) thermosensitive film and manufacturing method thereof

InactiveCN109955553AStrong surface strengthExcellent resistance to wet and dry frictionNon-fibrous pulp additionSynthetic resin layered productsPaper basedHigh surface

The invention discloses a hot water-resistant biaxially oriented polypropylene (BOPP) thermosensitive film and a manufacturing method thereof. The BOPP thermosensitive film comprises a BOPP base film,a connecting layer, a color development layer and a protective layer, wherein the connecting layer, the color development layer and the protective layer are sequentially arranged on the BOPP base film. The preparation method of the hot water-resistant BOPP thermosensitive film comprises the following steps: (1) selecting a BOPP film with two glossy surfaces as a coating base material; (2) preparing a coating liquid of the connecting layer; (3) preparing a coating liquid of the color development layer; (4) preparing a coating liquid of the protective layer; and (5) separately pumping the coating liquids into a material tank of a coating machine, and sequentially coating the paper base material with the connecting layer, the color development layer and the protective layer by adopting a metering rod coating method. The product coating disclosed by the invention has extremely high surface strength, excellent dry-wet friction resistance and excellent hot water resistance, and can be usedin hot water or hot steam. According to the connecting layer disclosed by the invention, double components of hydroxyl-containing self-crosslinked acrylate and polyisocyanate are used for crosslinkingand film forming, the combination firmness of the BOPP film with the color development layer is enhanced, and a hot water-resistant effect is achieved.

Owner:JIANGSU WANBAO RUIDA HI TECH CO LTD

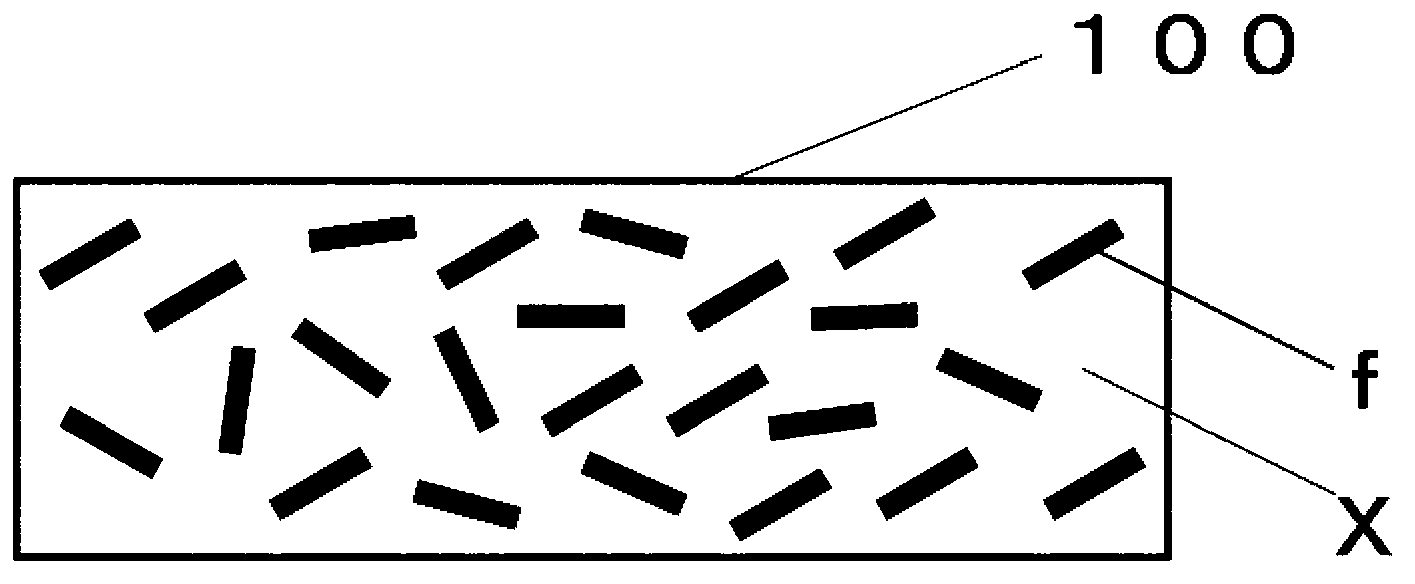

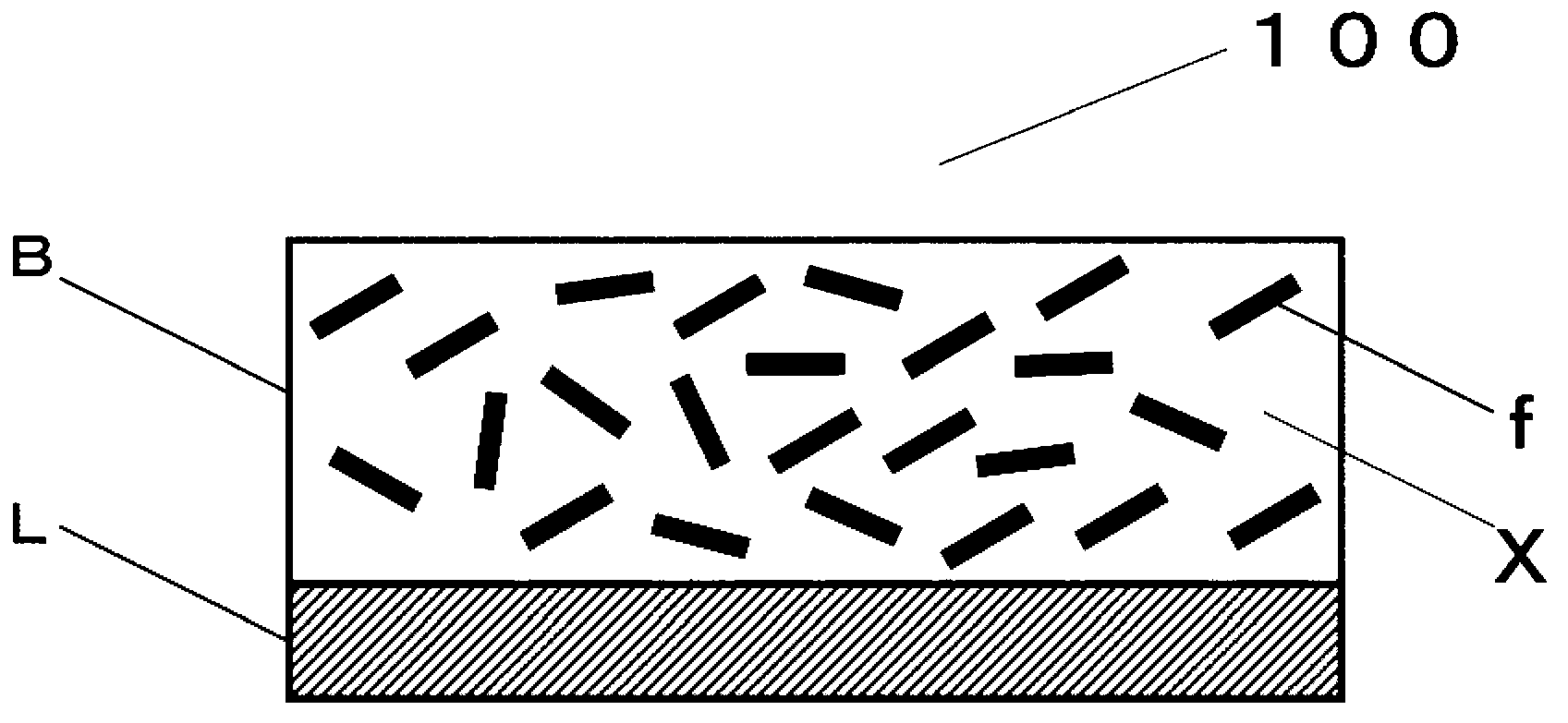

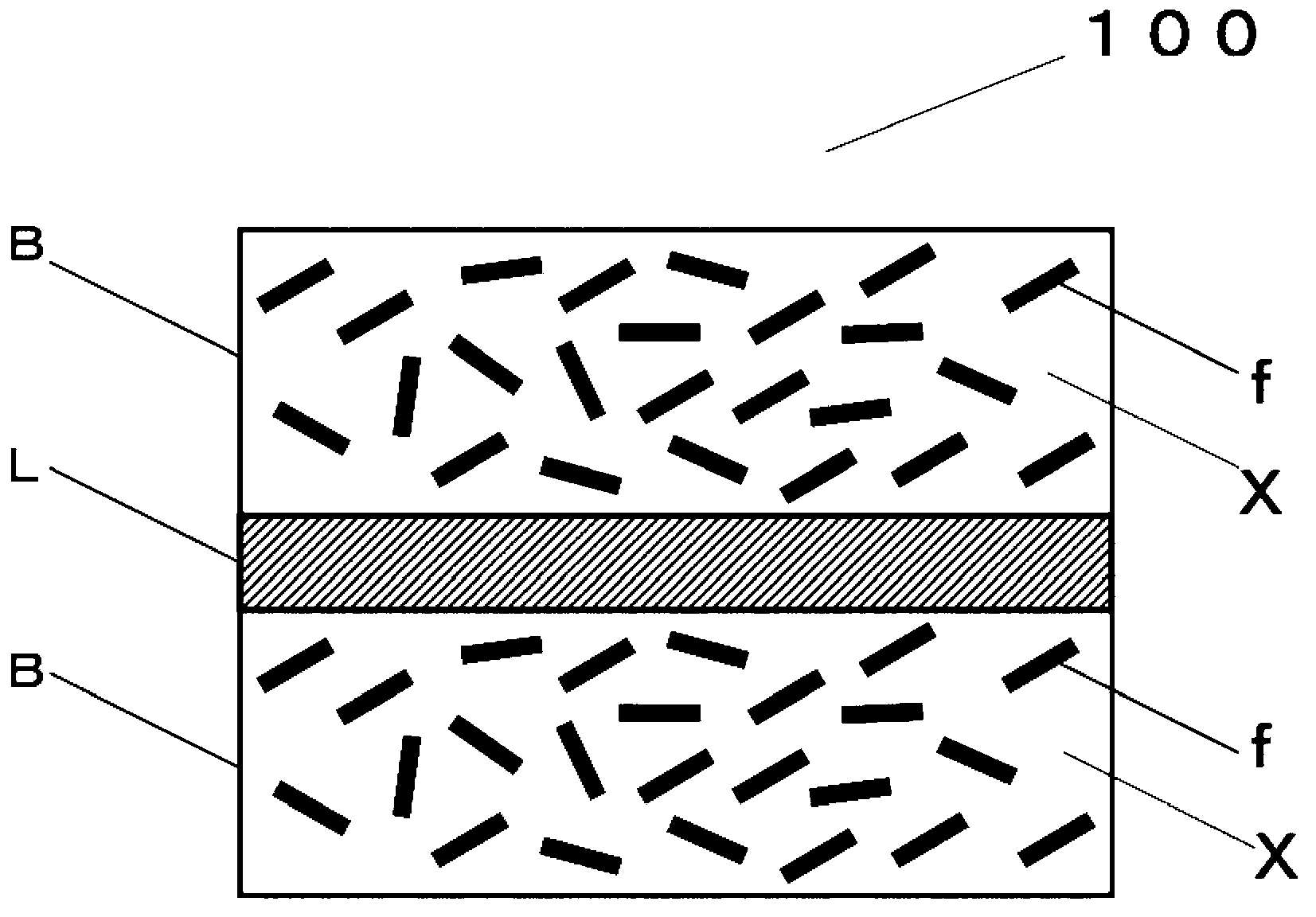

Polymer member having resistance to cigarette burns, article with resistance to cigarette burns, and method for providing resistance to cigarette burns

InactiveCN103339204AStay flexibleExcellent resistance to cigarette burnsProtective equipmentFilm/foil adhesivesPolymer scienceChemical compound

Provided is a member which has excellent transparency and flexibility and is capable of providing various objects with resistance to cigarette burns by being bonded to the various objects. A polymer member of the present invention comprises a polymer layer and has resistance to cigarette burns. The polymer layer contains a layered inorganic compound (f) in a polymer (X), and the polymer (X) contains a crosslinked polymer.

Owner:NITTO DENKO CORP

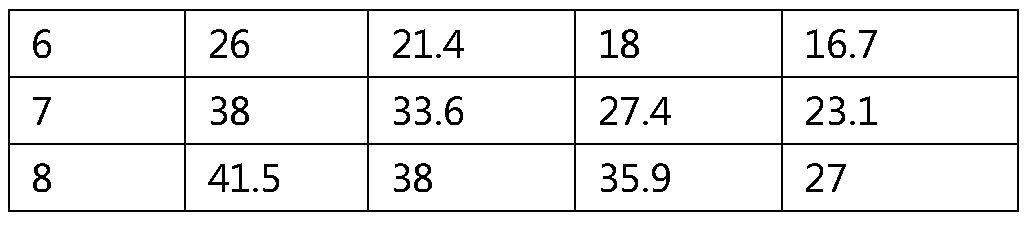

Semitransparent colorful heat transfer film and preparation method thereof

ActiveCN105691073ASymphony effect is goodImprove anti-corrosionDecorative surface effectsVacuum evaporation coatingMetalNanotechnology

The invention discloses a semitransparent colorful heat transfer film and a preparation method thereof. The semitransparent colorful heat transfer film comprises a PET film, wherein the PET film is sequentially coated with a release layer, an aluminizing layer and a colorful layer; the aluminizing layer is 9 to 11 nm in thickness; the aluminizing layer with the thickness can ensure that the heat transfer film presents a relatively good colorful effect and has translucence and metallic luster; besides, through the aluminizing layer, a color layer can be protected, and the corrosion resistance and abrasion resistance of the heat transfer film are improved; and the semitransparent colorful heat transfer film is low in cost, easy and convenient in production technology, and good in semitransparent and colorful effects.

Owner:SUZHOU WONDERFUL NEW MATERIAL CO LTD

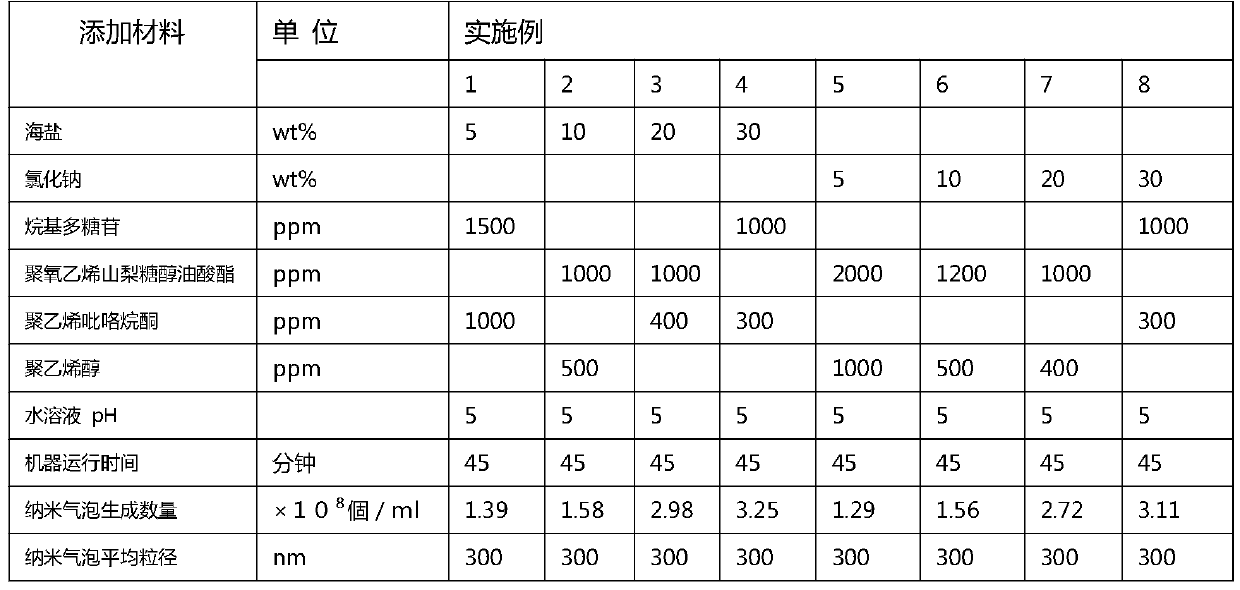

Ozone nanobubble mouthwash and preparation method

ActiveCN111467266AFor long-term storagePossibility of commercializationCosmetic preparationsToilet preparationsBad mouth tasteAqueous solution

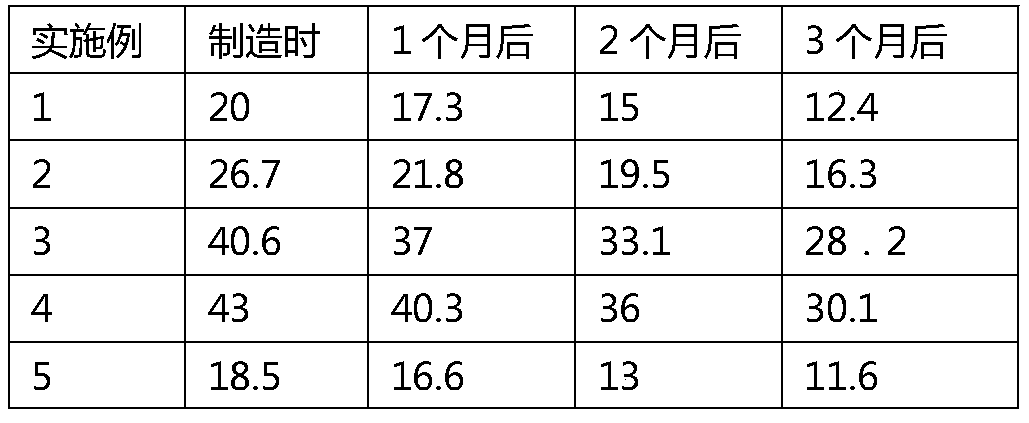

The invention provides a preparation method for ozone nanobubble mouthwash capable of maintaining ozone concentration for a long time at room temperature. By using a microbubble generator, ozone nanobubbles are made in an aqueous solution in which a bubble retention agent is dissolved; the ozone nanobubbles of which the number exceeds 129x108 / 100mL and the particle sizes are less than 500nm are generated, and the bubbles can stay in the aqueous solution stably for a long time. The ozone concentration of the ozone nanobubble mouthwash is within a range of 18.5-43mg / L, and after the ozone nanobubble mouthwash is hermetically stored in a dark place for three months at room temperature, the ozone concentration of the ozone nanobubble mouthwash can still maintain 60% or more of the ozone concentration when the ozone nanobubble mouthwash is prepared. The ozone nanobubble mouthwash can be applied to the field of preventing and treating oral diseases, eliminating ozostomia, whitening teeth andthe like.

Owner:深圳市陆讯纳米科技有限公司

A kind of matt elastic thermal transfer film and preparation method thereof

ActiveCN105694076BImprove friction resistanceStretchablePolyurea/polyurethane coatingsThermographyThermal printingSilicon

The invention discloses a matt elastic thermal transfer film and a preparation method thereof. The film comprises a PET base film which is sequentially coated with a matt precoated layer, a release layer, a coloring layer and an elastic glue layer. The matt precoated layer is an acrylic acid modified silicon resin layer; due to the matt precoated layer, the thermal transfer film has a matt effect, and the friction resistance of the thermal transfer film can be improved; the release layer is made from organic silicon resin, has stripping performance, can be disengaged from the thermal transfer film after being heated in the thermal printing process and can be attached to the surface of the coloring layer to form a protecting layer; the coloring layer is formed by mixing and curing dye and resin, and the color of the thermal transfer film can be changed by adjusting the dye components and the resin concentration; the elastic glue layer is a resin glue layer and has elasticity, and the thermal transfer film can have tensile performance and can be stretched when elastic cloth is stretched; the coloring layer can be stretched when the elastic cloth is stretched after thermal printing transfer, high matt degree and friction resistance are achieved, and the grade of the product is improved.

Owner:SUZHOU WONDERFUL NEW MATERIAL CO LTD

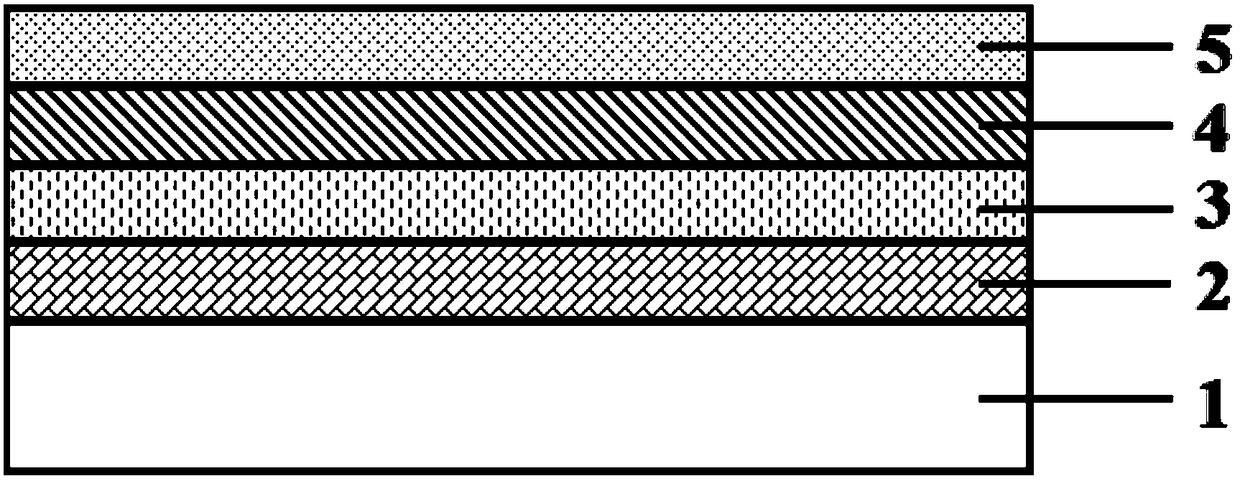

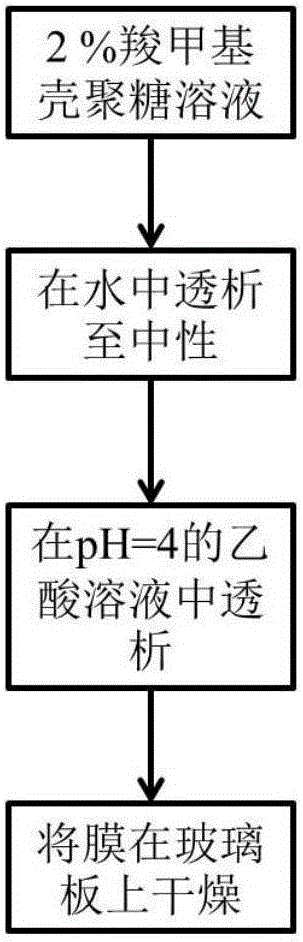

Method for preparing carboxymethyl chitosan film through dialysis and application of carboxymethyl chitosan film

InactiveCN106009013APeelableElasticIon-exchange process apparatusOther chemical processesMedicinePolysaccharide

The invention discloses a method for preparing a carboxymethyl chitosan film through dialysis and an application of the carboxymethyl chitosan film. The method comprises the following steps: 1) a carboxymethyl chitosan solution is poured into a dialysis bag and subjected to dialysis in water until the carboxymethyl chitosan solution is neutral; 2) the dialysis bag containing the neutral carboxymethyl chitosan solution is continuously soaked in an acid solution for dialysis and a layer of carboxymethyl chitosan film is deposited on the inner surface of the dialysis bag; 3) the carboxymethyl chitosan film obtained in the step 2) is transferred and dried. The carboxymethyl chitosan film is prepared with the dialysis bag as a template, is in the same shape as the dialysis bag and adopts a bag-shaped structure; the dialysis bag can be repeatedly used and is low in cost; the specific surface area of the prepared film is relatively large, and the carboxymethyl chitosan film can be used in fields such as selective dialysis, adsorption of heavy metal ions, dye adsorption, wastewater treatment and the like.

Owner:SHANDONG UNIV

Mine cable insulation shielding material and preparation method thereof

InactiveCN105440421AImprove heat resistanceImprove conductivityPlastic/resin/waxes insulatorsCross-linkCarvacryl acetate

A mine cable insulation shielding material comprises the following compositions in parts by weight: 100 parts of ethylene-vinyl acetate copolymer (EVA), 50-100 parts of conductive carbon black, 1-4 parts of a cross-linking agent, 1-4 parts of an auxiliary crosslinking agent, 5-15 parts of a lubricant, 5-25 parts of a softener, 1-3 parts of an anti-oxidant, and 1-3 parts of an anti-ageing agent. The preparation steps of the material comprises: a, weighing the raw materials for usage; b, blending, concretely uniformly blending conductive carbon black, the lubricant, the softener, the anti-oxidant and the anti-ageing agent, so as to obtain a mixture for usage; c, mixing, adjusting the roller distance of an open mill to be 1-2 mm, adding EVA, after rolling is finished, adding the mixture, mixing for 8-10 min, then adding the crosslinking agent and the auxiliary crosslinking agent, and mixing for 2-3 min, keeping the roller temperature to be 65-75 DEG C in the rubber mixing process, and controlling the mixing time to not exceed 20 min, and performing thin passing for five times, and discharging a sheet.

Owner:ZHEJIANG XINGLE HIGH POLYMER MATERIAL CO LTD

Mirror surface multicolor film preparation process based on raw material adjustment

InactiveCN112024332AMade preciselyImprove film production efficiencyCoatingsSpecial surfacesControl systemMaterials science

The invention relates to a mirror surface multicolor film preparation process based on raw material adjustment. The mirror surface multicolor film preparation process comprises a release layer preparation unit, a multicolor layer preparation unit, a coating unit and a central control unit. According to the mirror surface multicolor film preparation process, by arranging the central control unit ina system and connecting the central control unit with designated equipment in the system, the central control unit can calculate the area S for preparing a multicolor film according to the size of aselected to-be-prepared film, select the designated raw material consumption according to the area and adjust the operation parameters of the corresponding parts, and thus the materials for preparingare used to the greatest extent while the high-curing multicolor film is prepared; and the central control unit is provided with an S0 matrix, a T1 matrix, a T2 matrix, a T3 matrix, an A0 matrix groupand a D0 matrix group, the central control unit can establish an Ri matrix group according to the comparison result of the area S of the to-be-prepared multicolor film and each parameter in the S0 matrix so as to select a specified parameter to control the raw material consumption in the system and the operation parameters of each specified part, so that the multicolor film can be prepared more accurately, and the film preparation efficiency of the system can be further improved.

Owner:瑞年科技(广东)有限公司

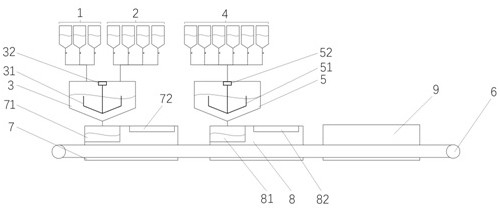

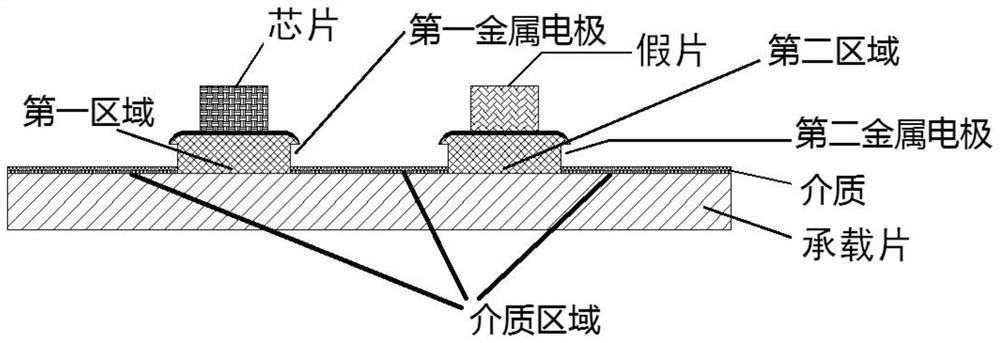

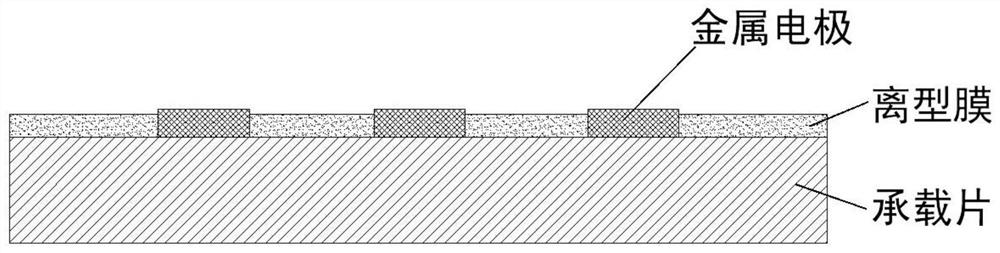

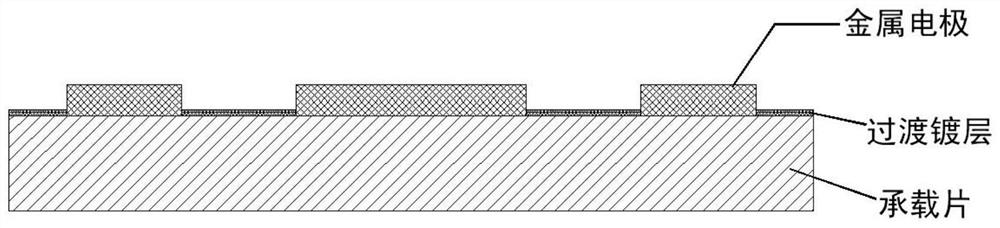

A kind of encapsulation carrier board, encapsulation body and technology thereof

ActiveCN111863633BSimple structurePeelableSemiconductor/solid-state device detailsSolid-state devicesMetallic electrodeEngineering

A packaging carrier for carrying a package including a chip, including: a carrier sheet and a medium thinner than the carrier sheet; the medium includes any of the following: a release film, a transitional coating, or other materials that can be combined with the package or the carrier The sheet forms a medium with weak bonding force; for at least one side of the carrier sheet, a part of the area belongs to the medium area, and the rest of the area includes at least the first area and the second area, and the first area belongs to the first area on which the chip is connected. A region to which a metal electrode is attached, the second region belongs to the second region to which a second metal electrode connected with a dummy sheet is attached, and the thickness of the dummy sheet is consistent with the thickness of the chip; the carrier sheet can be relative to the package The body is stripped and reused for encapsulating the carrier. In this way, the present disclosure realizes a packaging carrier board that is simpler, avoids wire bonding to the greatest extent, is more environmentally friendly, and lower in cost.

Owner:深圳市鼎华芯泰科技有限公司

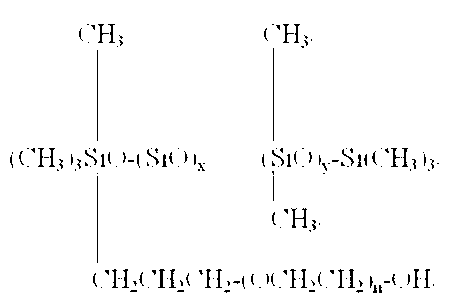

Preparation method of water-soluble strippable protective coating

The invention relates to a preparation method of a water-soluble strippable protective coating. The preparation method comprises the following steps of: (1) adding potassium persulfate and n-dodecyl mercaptan to acrylic acid; (2) placing a container filled with products in a water bath pot at 63-67 DEG C and stirring for 30mutesin; (3) adding gas phase silicon dioxide and water-soluble polyether modified polysiloxane to the products; (4) adding polyethylene glycol with molecular weight of 6000 and adjusting to appropriate viscosity by water for brush coating; and (5) after the coating is volatilized, curing for 10minutes in an oven at 65-75 DEG C to obtain the strippable protective coating.

Owner:NANCHANG HANGKONG UNIVERSITY

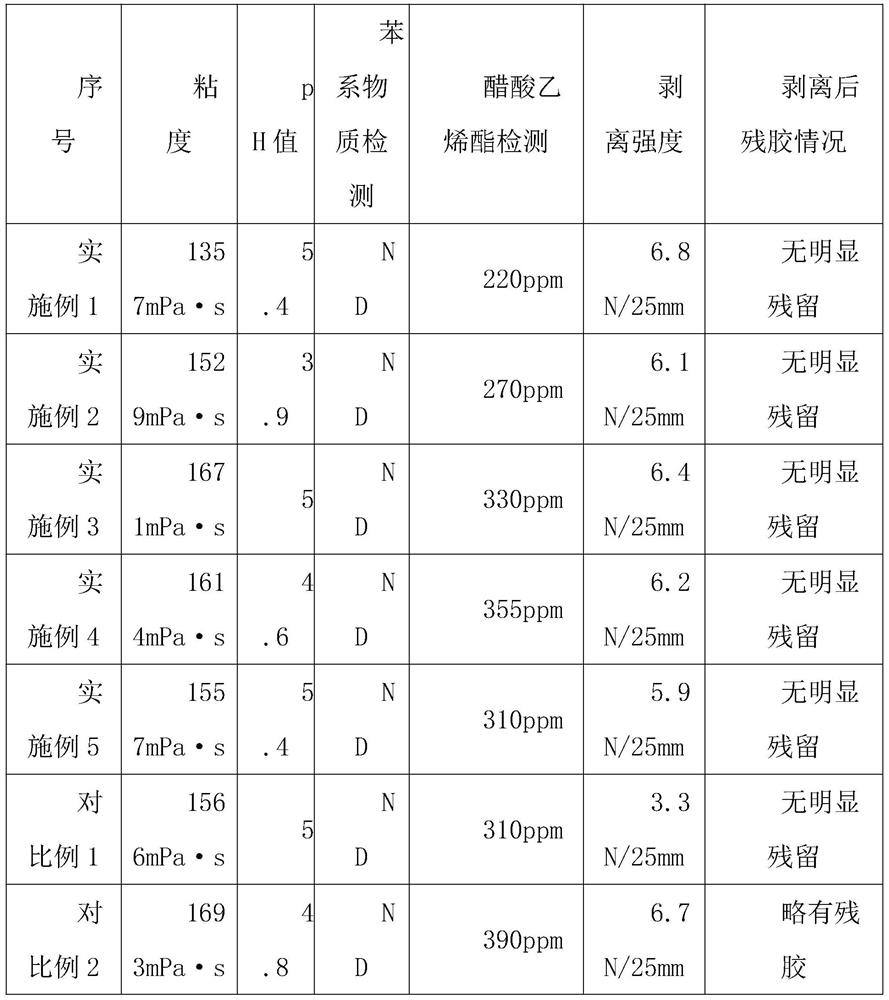

A kind of cigarette water-based laser packaging glue and preparation method thereof

ActiveCN109294488BImprove toughnessImprove thixotropyMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesAlcoholEmulsion

The invention relates to a water-based laser packaging glue used for cigarettes and a preparation method thereof. The water-based laser packaging glue consists of the following components: a VAE emulsion, nano alumina / crystal alumina, calcium chloride, polyvinyl alcohol, alcohol, a nonionic emulsifier, an environmental protection agent, a preservative, and water. Compared with the prior art, the water-based laser packaging glue has the characteristics of fast drying speed, strong cohesive force, good fluidity, no toxicity, no odor, no corrosion, no burning, and storage resistance. The productquality and various technical performance indicators are superior to similar products, especially in terms of drying speed, bond strength and fluidity, which can be increased by 60% based on the past.The water-based laser packaging glue strictly implements the requirements of the People's Republic of China tobacco industry standard-Volatile and semi-volatile components of tobacco water-based glue, formaldehyde is less than 20ppm, ethyl acetate is less than 400ppm, and the water-based laser packaging glue is inspected by the National Tobacco Quality Supervision and Inspection Center.

Owner:湖北恒阳科技发展有限公司

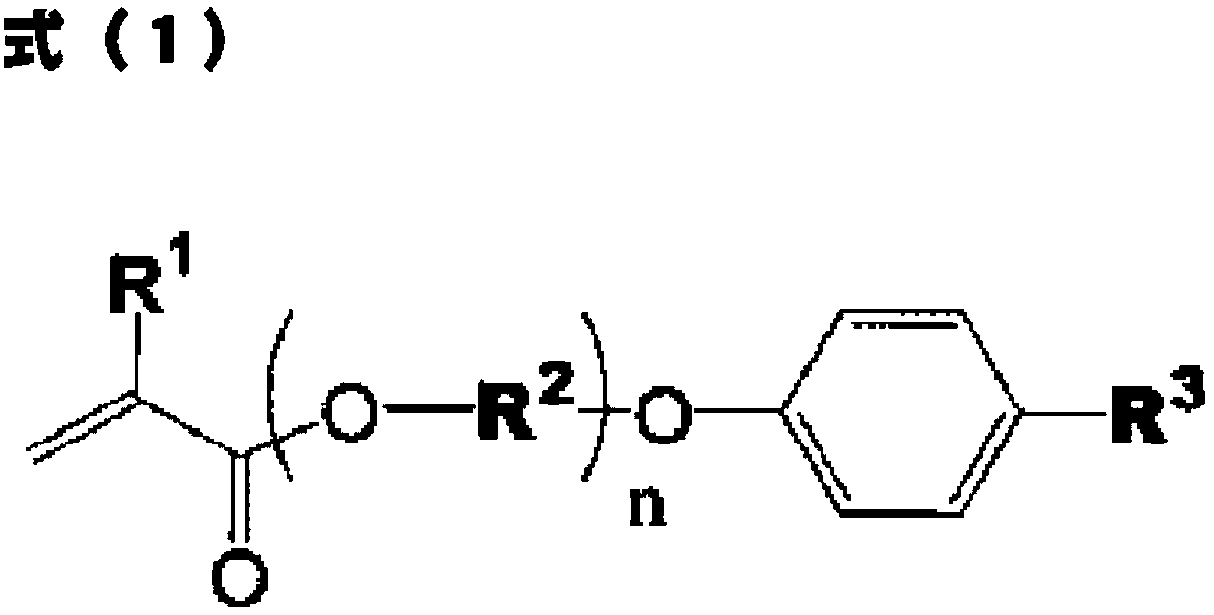

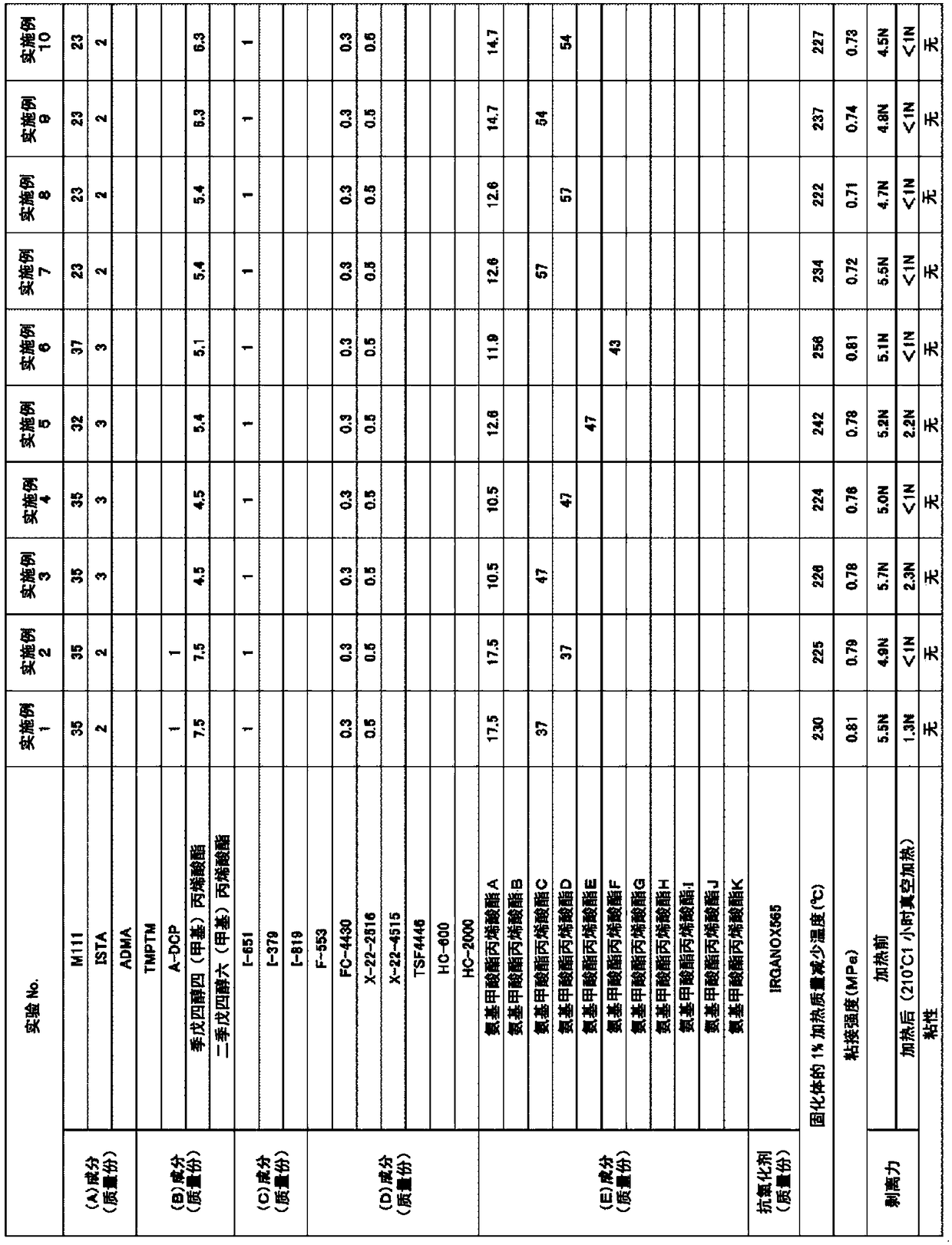

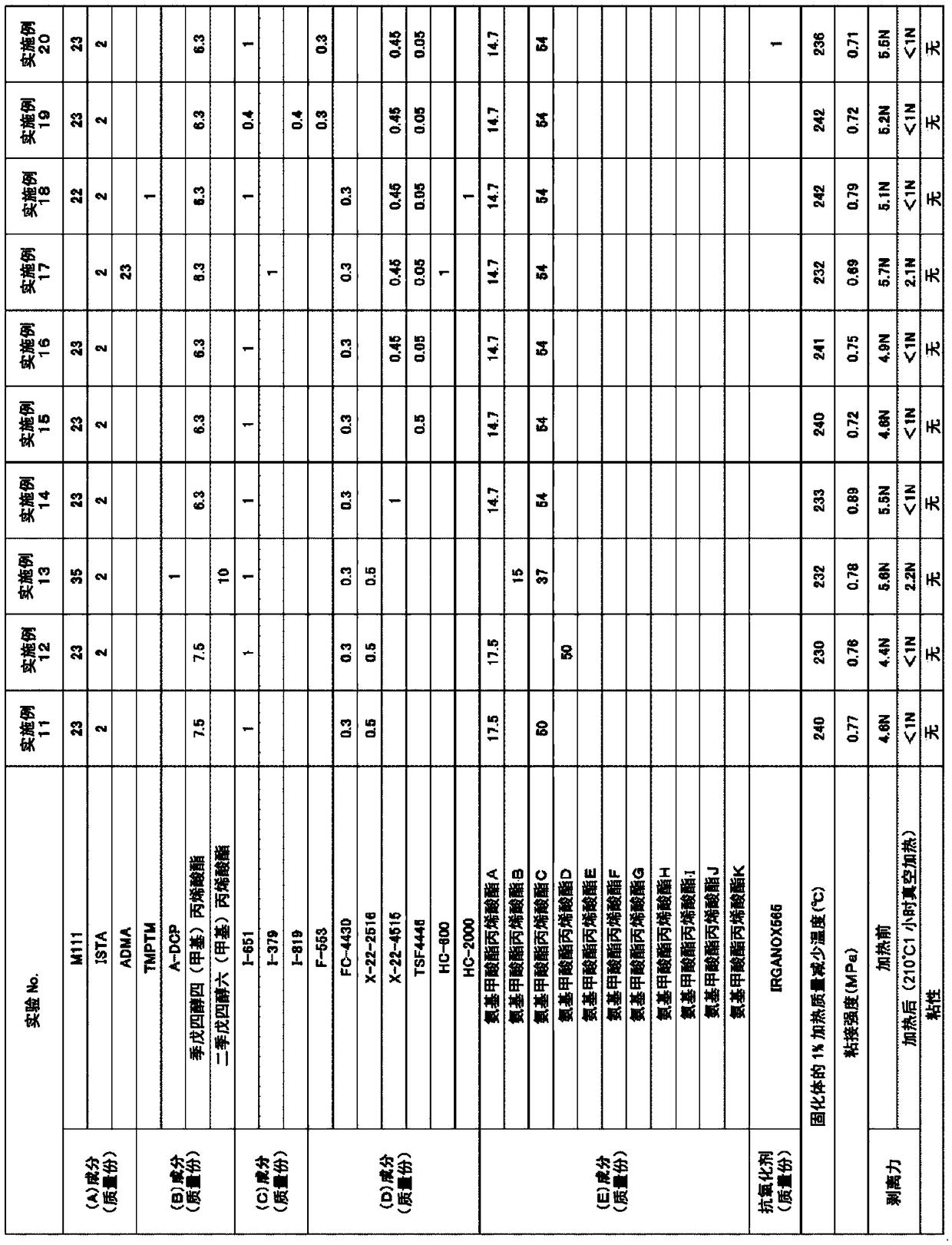

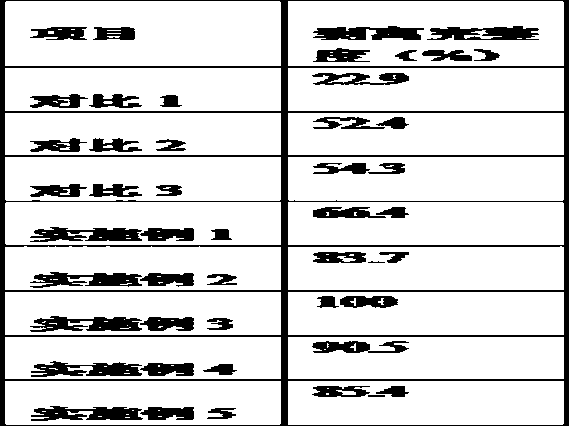

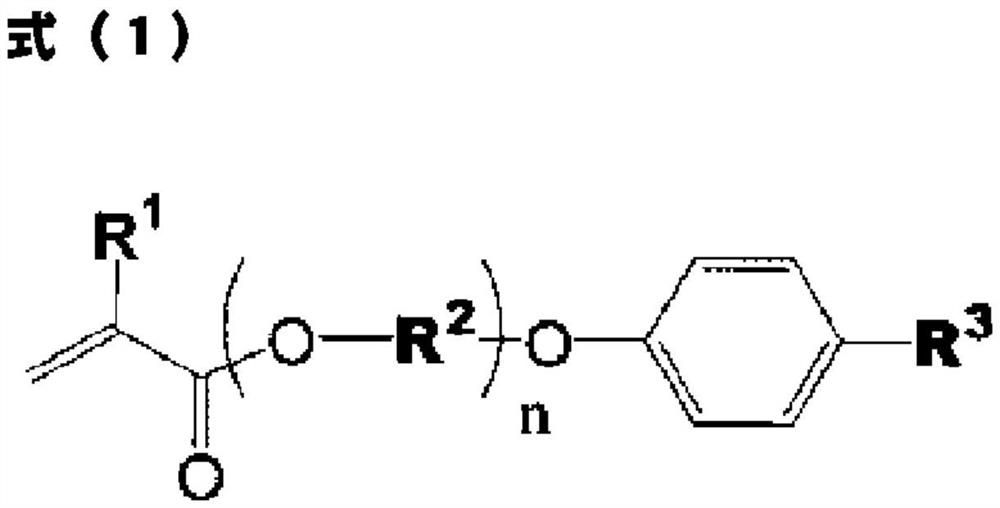

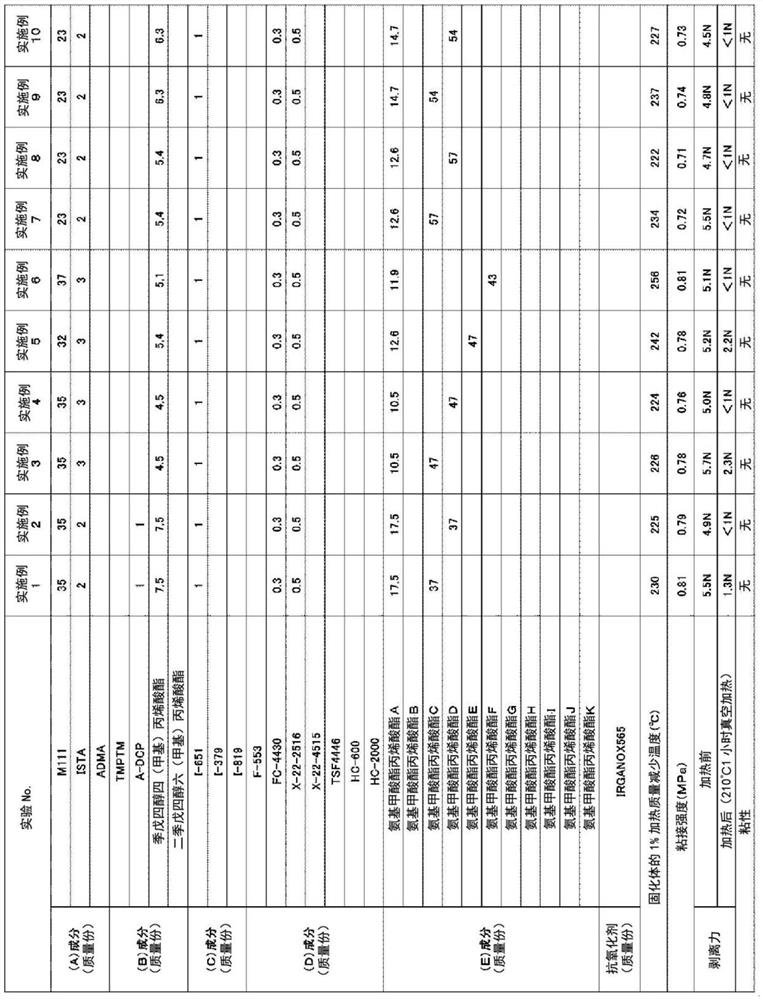

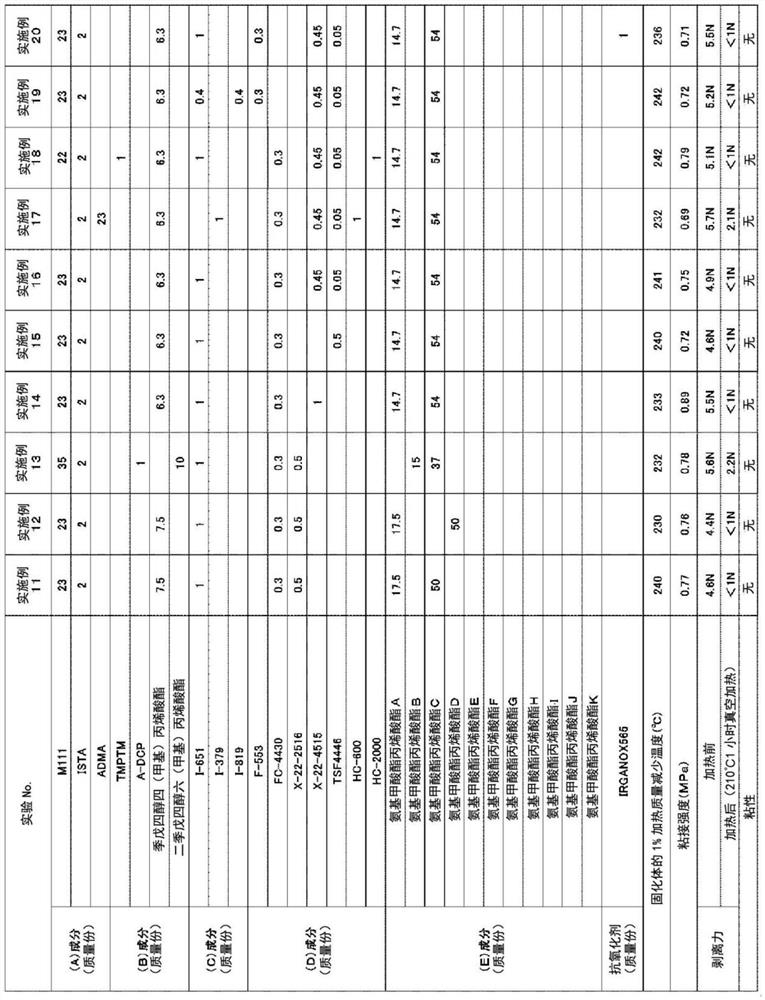

Composition

ActiveCN109415473AHeat resistantAdhesiveNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer chemistryAdhesive

A composition having heat resistance, adhesiveness, and strippability is provided. The composition comprises the following components (A) to (E): component (A) is a monofunctional (meth)acrylate having a number-average molecular weight less than 1,000; compound (B) is a polyfunctional (meth)acrylate having a number-average molecular weight less than 1,000; compound (C) is a radical polymerizationinitiator; component (D) is a strippability-imparting compound; and component (E) is a polyfunctional urethane (meth)acrylate. The composition gives a temporary fixing adhesive for semiconductor manufacturing.

Owner:DENKA CO LTD

A kind of UV-curable adhesive doped with nano-titanium dioxide and its preparation method

ActiveCN107502272BSuitable Thixotropic ViscosityReduce hardnessNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention relates to an ultraviolet light curing adhesive doped with nano titanium dioxide and a preparation method of same. The ultraviolet light curing adhesive is composed of, by weight, 20-60 parts of a self-made bifunctional polyurethane-acrylate prepolymer, 5-15 parts of a multifunctional polyurethane-acrylate prepolymer, 5-15 parts of a polyester-acrylate prepolymer, 5-20 parts of a reactive amine compounding agent, 10-30 parts of an acrylate-type activity diluent, 0.5-5% of a flatting and wetting agent, 1-5% of a photoinitiator, 0.5-3 parts of titanium dioxide nano-powder, and 0.1-10 parts of fumed silica. The ultraviolet light curing adhesive is suitable for temporary protection for metal shells, has protective effect during a later-period treatment process of CNC and can be easily stripped-off after the CNC machining. The adhesive has no residue and stripping off on the metal shells.

Owner:YANTAI SEAYU NEW MATERIALS CORP LTD

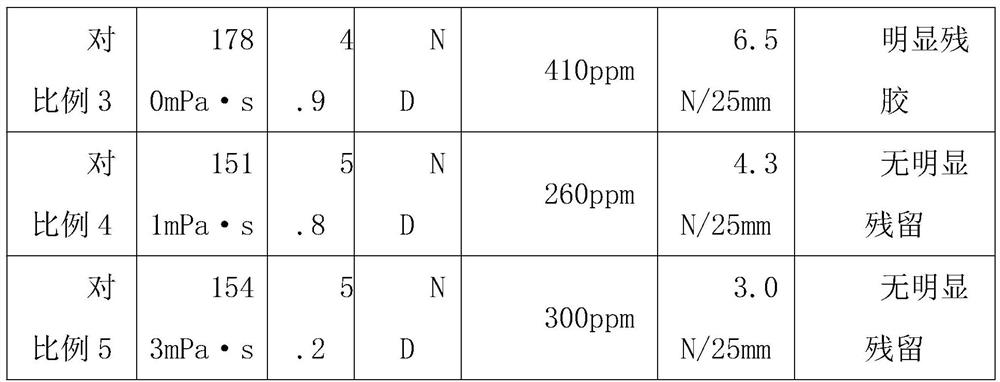

combination

ActiveCN109415473BHeat resistantAdhesiveNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesMethacrylateMeth-

To provide a composition having heat resistance, adhesiveness, and peelability. A composition containing the following (A) to (E) components. (A) component, monofunctional (meth)acrylate with number average molecular weight less than 1000; (B) component, multifunctional (meth)acrylate with number average molecular weight less than 1000; (C) component, free radical polymerization initiator ; (D) component, compound for imparting mold release; (E) component, polyfunctional urethane (meth)acrylate. A temporary fixing adhesive for semiconductor manufacturing comprising the composition.

Owner:DENKA CO LTD

Polyurethane dispersion modified polyacrylate pressure-sensitive adhesive and preparation method thereof

PendingCN112341960AImprove performancePeelablePolyureas/polyurethane adhesivesEster polymer adhesivesPolyurethane dispersionPolymer science

The invention discloses a polyurethane dispersion modified polyacrylate pressure-sensitive adhesive and a preparation method thereof, and the polyurethane dispersion modified polyacrylate pressure-sensitive adhesive is characterized in that the weight percentage ratio of polyurethane dispersion to polyacrylate is (5-20%): (80-95%). The polyurethane dispersion is a waterborne anionic polyurethane dispersion, and the polyacrylate is prepared from water, a soft monomer, a polar monomer, a surfactant monomer, an initiator and a pH buffer agent as raw materials by adopting an emulsion polymerization method. When the polyurethane dispersion modified polyacrylate pressure-sensitive adhesive is used, additives do not need to be added, the problems that an adhesive layer of an existing pressure-sensitive adhesive is damaged, the existing pressure-sensitive adhesive is prone to falling off from the surface of a base material, adhesive residues exist and the like can be solved, and the bonding strength of the pressure-sensitive adhesive is improved.

Owner:HUNAN UNIV OF HUMANITIES SCI & TECH

Method for preparing trimethylolpropane-tri-(2-methyl-1-aziridine) propionate

A method for preparing trimethylolpropane-tri-(2-methyl-1-aziridine) propionate comprises the steps of mixing trimethylolpropane with acrylic acid, and adding cerous sulfate, hydroquinone and methylbenzene; conducting stirring heating and reflux reaction, adding water, conducting stirring, conducting stand-layering, and removing liquid on the lower layer; reserving liquid on the upper layer, conducting washing with sodium hydroxide solution and then with saturated sodium chloride solution, and finally conducting washing with water; conducting heating, standing for 30 min, adding hydroquinone, and conducting rotary steaming to obtain faint yellow transparent liquid; placing the transparent liquid in an ice bath, adding 2-methyl aziridine dropwise while stirring, and moving the liquid to a brown bottle; placing the brown bottle at room temperature away from light to obtain trimethylolpropane-tri-(2-methyl-1-aziridine) propionate. The peel strength of a peelable protective film prepared from cured waterborne polyurethane dispersoid is 300-500 n / m.

Owner:NANCHANG HANGKONG UNIVERSITY

A kind of ultraviolet curing adhesive for temporary protection and preparation method thereof

ActiveCN107474786BSuitable Thixotropic ViscosityReduce hardnessNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention relates to an ultraviolet curing adhesive for temporary protection and a preparation method of the ultraviolet curing adhesive. The ultraviolet curing adhesive is prepared from the following raw materials by weight: 20-60 parts of a self-made bifunctional polyurethane acrylate prepolymer, 5-15 parts of a multi-functional polyurethane acrylate prepolymer, 5-15 parts of a polyester acrylate prepolymer, 5-20 parts of a reactive amine compounding agent, 10-30 parts of acrylate type active diluents, 0.5%-5% of a leveling wetting agent, 1%-5% of a photoinitiator, 0.5-5 parts of titanium dioxide nanowires and 0.1-10 parts of fumed silica. The ultraviolet curing adhesive is suitable for temporary protection of a metal casing and plays a protective role in post-processing of CNC, and can be easily peeled off after CNC processing. Residues on the metal casing and falling off of the adhesive are avoided.

Owner:YANTAI SEAYU NEW MATERIALS CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com