Creasing and folding resistance hot stamping foil for leather and preparation method thereof

A technology of hot stamping foil and folding resistance, which is applied in special decorative structures, decorative arts, decorative structures, etc. It can solve the problems of coating fog affecting product aesthetics, restricting product promotion and application, and single pattern, so as to improve aesthetics , strong flexibility, high transparency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

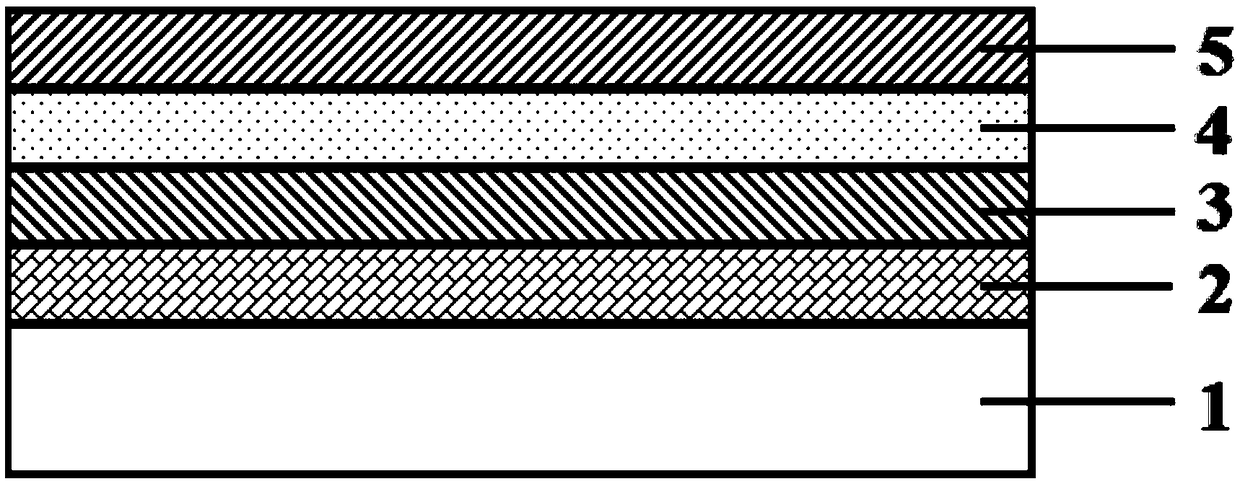

[0032] A preparation method for a folding-resistant white hot stamping foil for leather, comprising the following steps:

[0033] 1) Biaxially stretched polyester film is used as the base film, hereinafter referred to as PET base film;

[0034] 2) Coating on the surface of the PET base film to form a release layer: mix 20% PU elastic resin and water to obtain a release layer coating; use a screen roller to apply the release layer material solution to the surface of the matte pre-coating , and then react and dry in a 4-stage high-temperature oven to form a release layer;

[0035] 3) Coating on the surface of the release layer to form a colored layer: mix 15% acrylic resin, 5% amino resin, 5% hydroxyl-modified acrylic resin and 75% methyl ethyl ketone and stir for 15 minutes, then Add 1% dye and stir for 10 minutes, and finally add 0.1% accelerator and stir for 3 minutes to make the coloring layer material solution; apply the coloring layer material solution to the surface of t...

Embodiment 2

[0040] A preparation method for a folding-resistant white hot stamping foil for leather, comprising the following steps:

[0041] 1) Biaxially stretched polyester film is used as the base film, hereinafter referred to as PET base film;

[0042] 2) Coating on the surface of the PET base film to form a release layer: mix 30% PU elastic resin and methanol to obtain a release layer coating; use a screen roller to coat the release layer material solution on the surface of the matte pre-coating , and then react and dry in a 6-stage high-temperature oven to form a release layer;

[0043] 3) Coating on the surface of the release layer to form a colored layer: Mix 30% acrylic resin, 20% amino resin, 9% hydroxyl-modified acrylic resin and 50% butyl ester and stir for 30 minutes, then Add 11% dye and stir for 20 minutes, and finally add 2% accelerator and stir for 6 minutes to make the coloring layer material solution; apply the coloring layer material solution to the surface of the rel...

Embodiment 3

[0048] A preparation method for a folding-resistant white hot stamping foil for leather, comprising the following steps:

[0049] 1) Biaxially stretched polyester film is used as the base film, hereinafter referred to as PET base film;

[0050] 2) Coating on the surface of the PET base film to form a release layer: mix 25% PU elastic resin and alcohol to obtain a release layer coating; use a screen roller to apply the release layer material solution to the surface of the matte pre-coating , and then react and dry in a 4-stage high-temperature oven to form a release layer;

[0051] 3) Coating on the surface of the release layer to form a colored layer: Mix 20% acrylic resin, 15% amino resin, 5% hydroxyl-modified acrylic resin and 60% ethyl ester and stir for 20 minutes, then Add 5% dye and stir for 15 minutes, and finally add 1% accelerator and stir for 5 minutes to make the coloring layer material solution; use the screen roller to coat the coloring layer material solution on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com