Liquor aging device for liquor production

A liquor and ripening technology, which is applied in the field of liquor ripening devices for liquor production, can solve the problems of not being able to completely remove the miscellaneous taste of liquor, restricting the production and processing efficiency, affecting the aging efficiency, etc., so as to increase the sense of aged liquor and improve the flavor of liquor. , good effect of ripening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

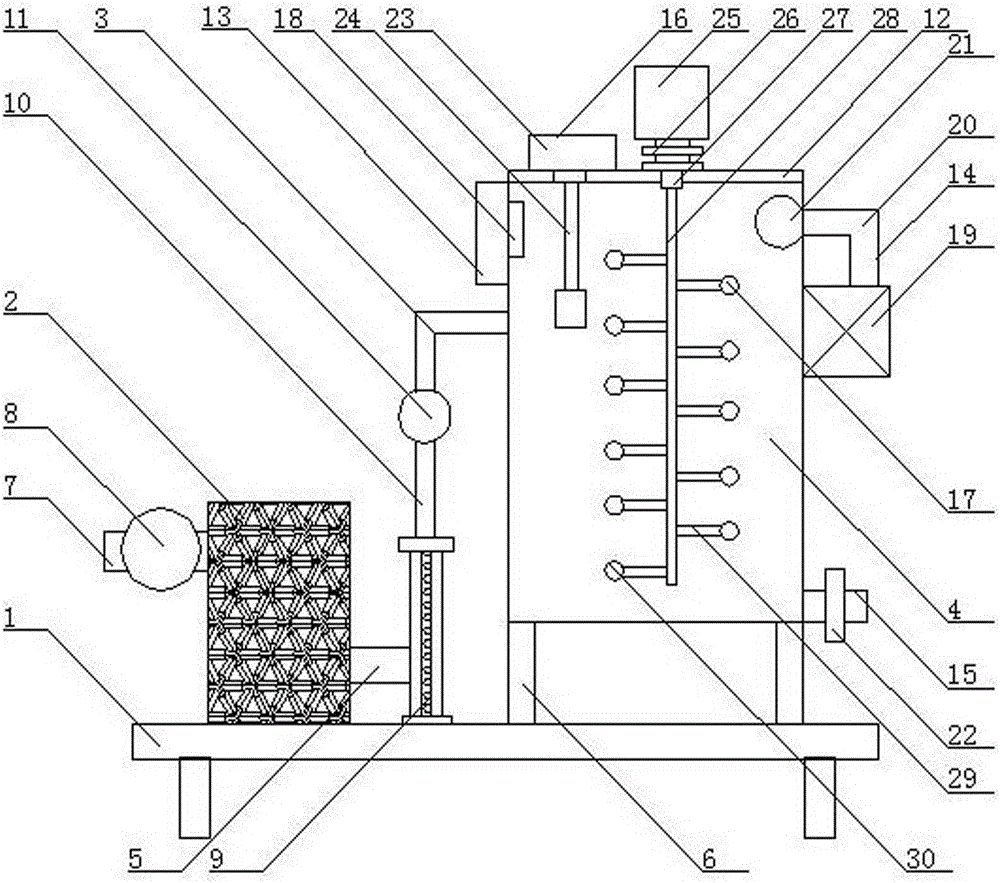

[0020] As shown in the figure, a liquor ripening device for liquor production includes a support 1, a precision filter cartridge 2, a liquid inlet device 3, and a ripening cartridge 4. The precision filter cartridge 2 is installed on the left side of the top of the support 1. The precision The lower end of the right side of the filter cartridge 2 is connected to the liquid inlet device 3 through the infusion tube 5, and the right side of the liquid inlet device 3 is equipped with a ripening cylinder 4, and the bottom end of the ripening cylinder 4 is fixed on the right side of the top of the bracket through a support leg 6.

Embodiment 2

[0022] As shown in the figure, a first liquid inlet pipe 7 is installed on the left side of the precision filter cartridge 2 , and a liquid inlet pump 8 is installed at the middle end of the first liquid inlet pipe 7 .

Embodiment 3

[0024] As shown in the figure, the liquid inlet device 3 is composed of a flow meter 9, a second liquid inlet pipe 10, and a liquid suction pump 11. The liquid inlet pipe 10, the middle end of the second liquid inlet pipe 10 is equipped with a liquid suction pump 11, and the upper end of the second liquid inlet pipe 10 is connected to the left side of the ripening cylinder 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com