Preparation method for reducing zirconium compound segregation of zirconium-containing magnesium alloy cast ingot ZK61M

A ZK61M, zirconium compound technology is applied in the field of preparation of reducing zirconium compound segregation of ZK61M zirconium-containing magnesium alloy ingots, which can solve problems such as Zr compound segregation, and achieve the effects of reducing segregation, improving ingot quality, and reducing melt impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0030] Embodiment 1: In this embodiment, a preparation method for reducing the segregation of zirconium compounds in ZK61M zirconium-containing magnesium alloy ingots is carried out according to the following steps:

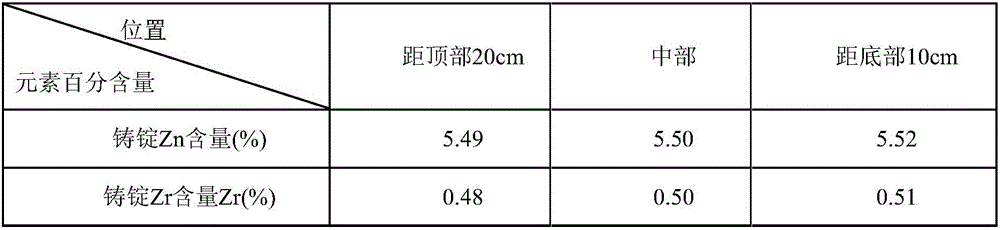

[0031]1. Weighing materials: Zn: 5.1% to 5.5%, Zr: 0.45% to 0.55% and the balance Mg according to the mass percentage of each element, respectively weigh zinc ingots, magnesium-zirconium master alloys and magnesium ingots as raw materials;

[0032] 2. Feeding and melting

[0033] First, evenly spread a layer of 2# flux on the bottom of the melting furnace, add the magnesium ingot weighed in step 1 into the melting furnace and evenly cover the upper surface of the magnesium ingot with 2# flux, heat the melting furnace until the magnesium ingot turns into a magnesium melt , put the zinc ingot and magnesium-zirconium master alloy weighed in step 1 into the incineration device, hoist the incineration device into the raw material heating furnace for preheating, and wh...

specific Embodiment approach 2

[0054] Embodiment 2: This embodiment differs from Embodiment 1 in that: the melting furnace described in Step 1 is a dry pot melting furnace. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

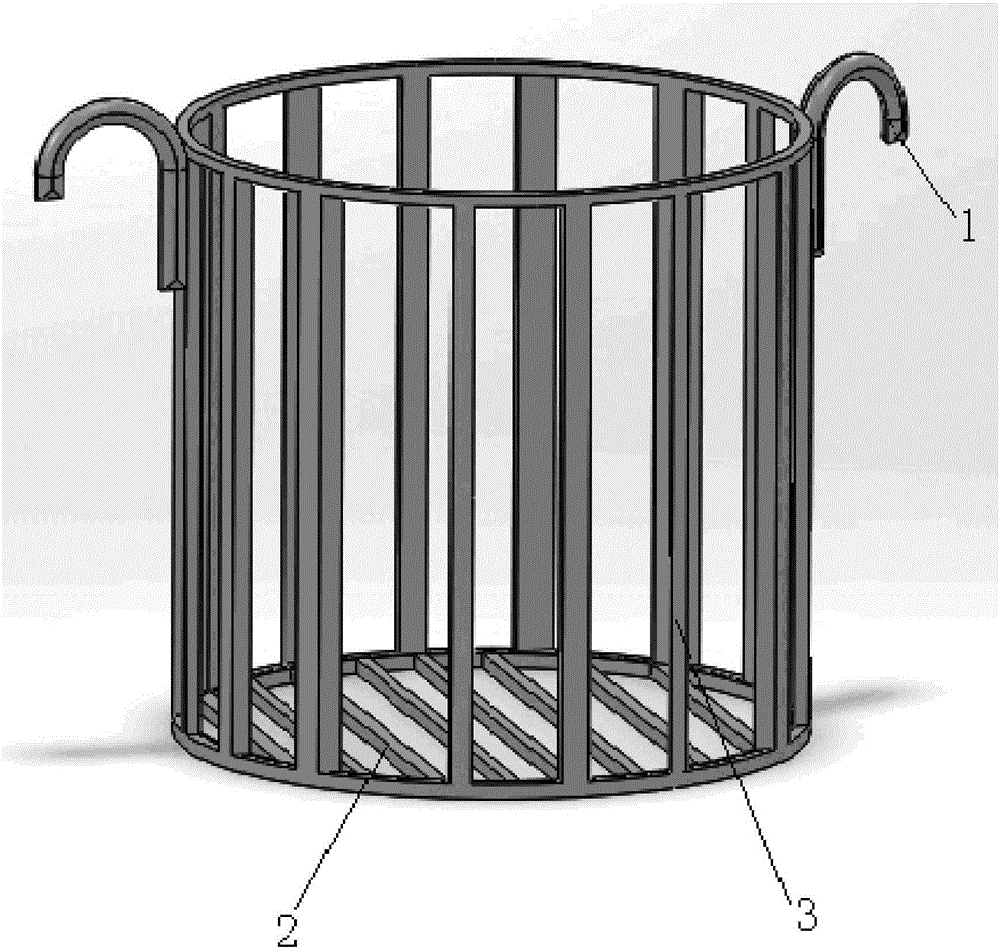

[0055] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the upper surface of the cylindrical metal cage described in step 1 is open, the lower surface is metal strips arranged in parallel horizontally, and the sides are metal strips arranged in parallel vertically. The upper part of the side is provided with a lifting hook. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com