A jet stirring device for filling the voids of a coarse-grained material dam body

A technology of coarse-grained materials and dam bodies, which is applied in the field of reinforcement of dangerous granular materials in water conservancy and hydropower projects. It can solve the problems of low pouring efficiency, large slurry consumption, and blockage of drill pipes, so as to achieve uniform distribution, realize filling, Effect of porosity control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, they are only examples, and the advantages of the present invention will become clearer and easier to understand.

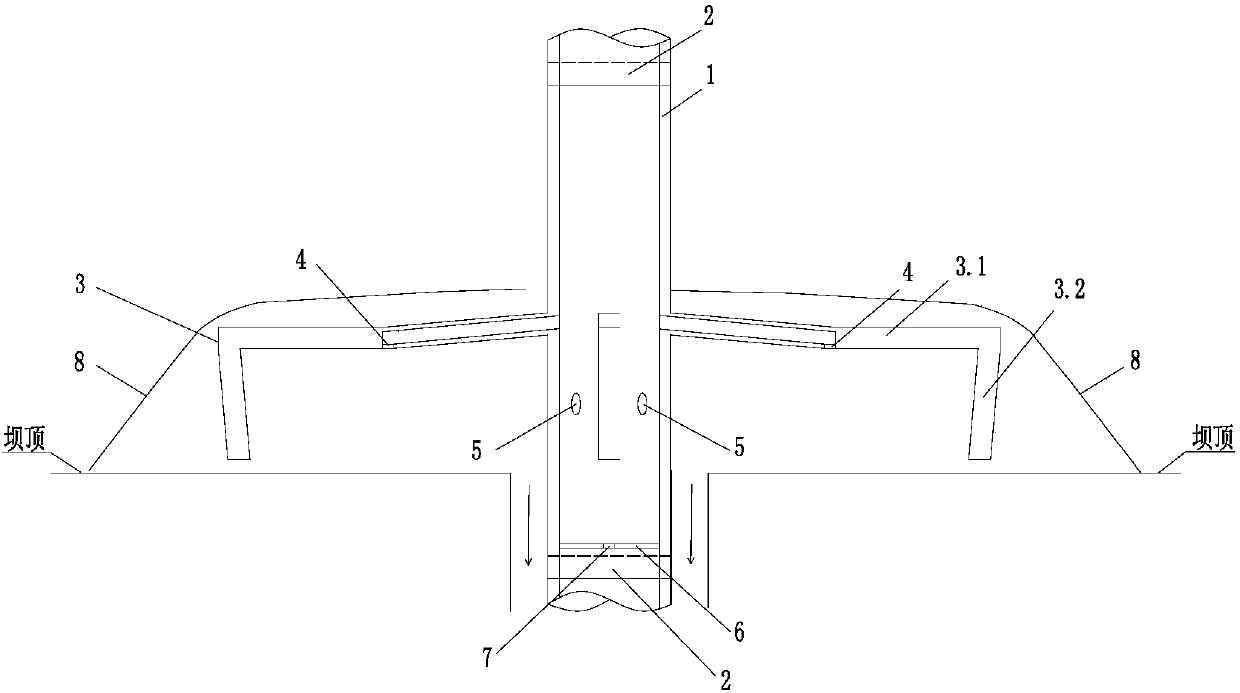

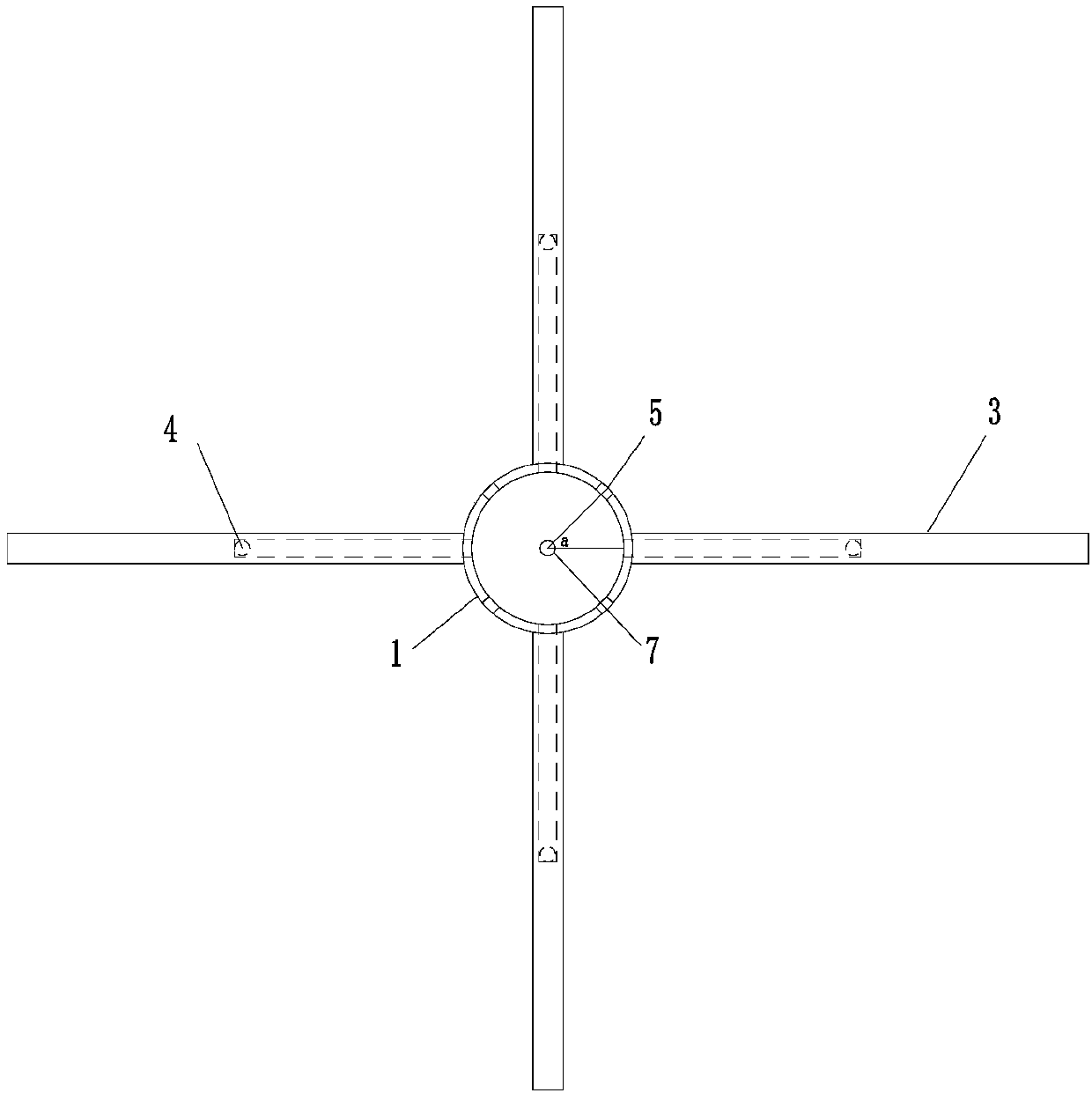

[0015] refer to Figure 1-2 Shown: a kind of jet agitation of the present invention fills the device of coarse-grained material dam body gap, is piled with sand material 8 around it,

[0016] It is characterized in that it includes a main shaft 1, a threaded connection body 2, an auxiliary stirring arm 3, a vertical grouting hole 4, a horizontal grouting hole 5, and a closing plate 6; the upper and lower ends of the main shaft 1 are connected to the drill pipe Through the threaded connection body 2 threaded connection; the four auxiliary stirring arms 3 are welded in a cross shape on the horizontal plane on the shaft arm of the main shaft 1 with a cavity structure insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com