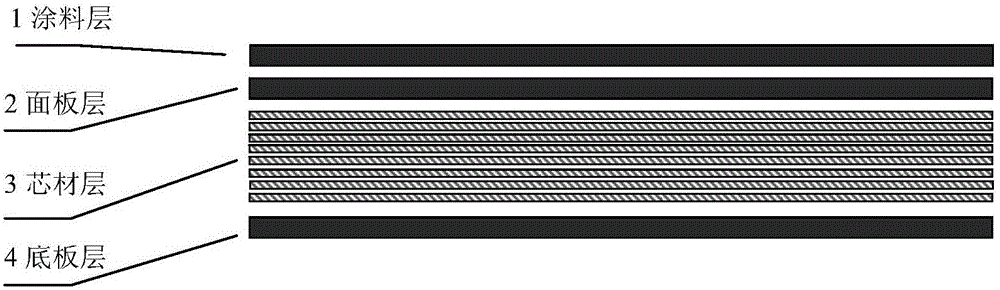

A composite floor board produced by using eucalypt wood laminated veneer lumber and a preparation process therefor

A technology of laminated veneer lumber and composite flooring, which is applied in the field of wood, can solve the problems of uneven wood density, short fast-growing eucalyptus wood fibers, and easy warping and deformation, and achieve the effect of improved flatness and uniform moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

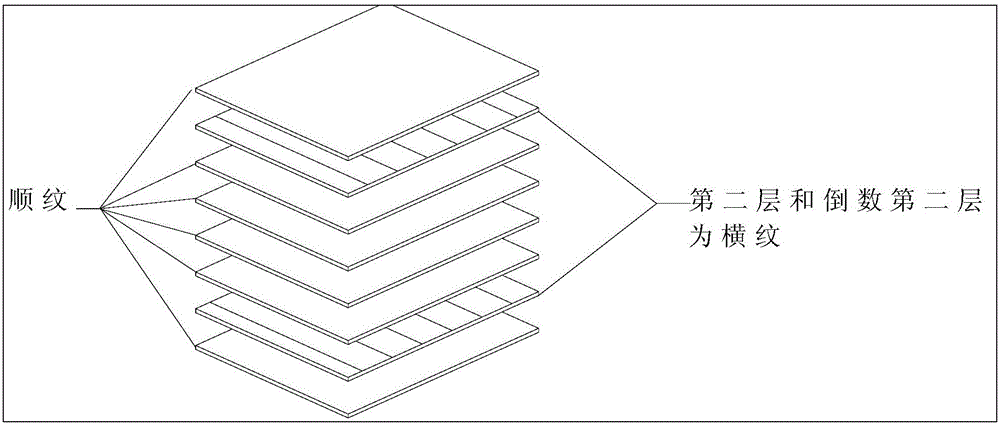

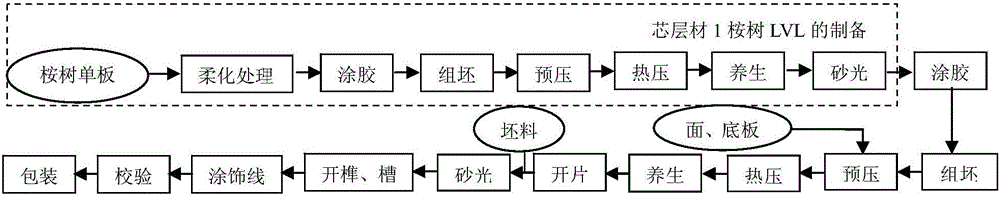

[0025] First carry out the preparation of core layer material, comprise the following steps:

[0026] 1) Eucalyptus veneer hot-pressing pretreatment process: Take the eucalyptus veneer with a thickness of 1.7-2.2mm and a moisture content of 10-14% and carry out a hot-pressing process in a hot press for 1-2 minutes. The control parameters of the hot press are Temperature 100~120℃, pressure 0.80~1.0MPa;

[0027] 2) Gluing process of eucalyptus veneer: apply modified starch adhesive to the eucalyptus veneer treated in step 1), the amount of glue applied is 280-320g / m2; the adhesive uses self-made corn modified starch glue, Corn starch is used as the main raw material, polyvinyl alcohol solution is used as the thickener, flour is used as the filler, and polyisocyanate prepolymer is used as the reinforcing agent for configuration. The appearance is a milky white uniform emulsion with a solid content of 45% and a pH value of 6~ 7. The viscosity is 5000-7500mPa.s, and the storage pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com