All-digital intelligent dry oil lubricating system

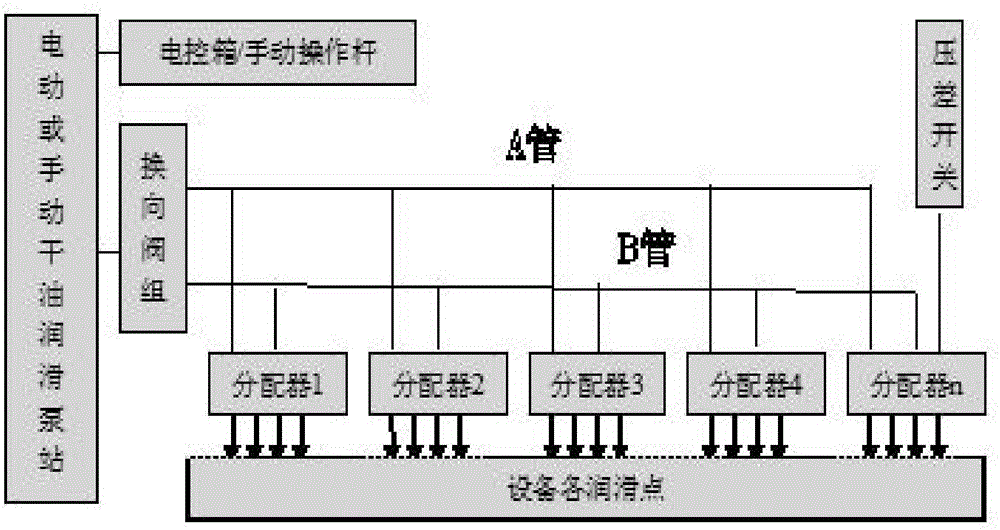

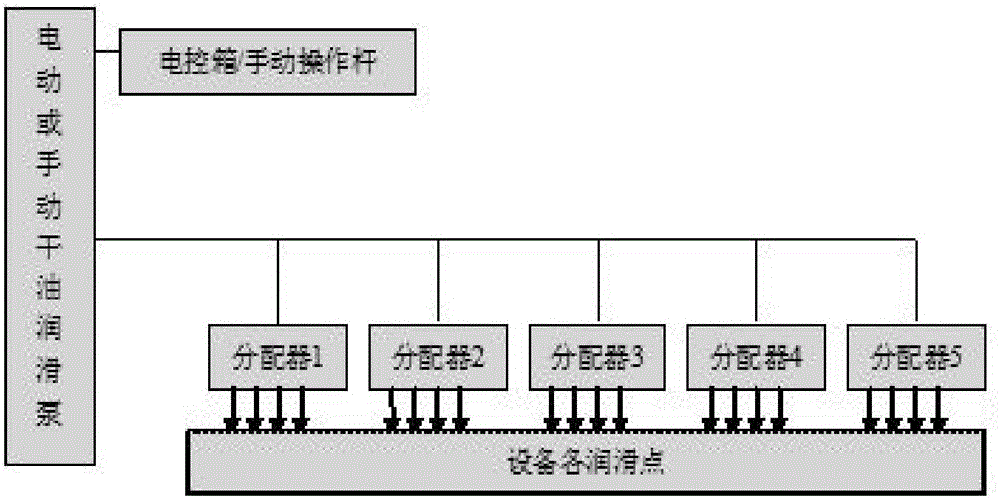

A lubricating system, all-digital technology, applied in the field of lubricating systems, can solve problems such as many failure points, complex system pipelines, poor maintenance, etc., and achieve the effects of accurate grease replenishment amount and grease replenishment interval, intuitive images, and optimized structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

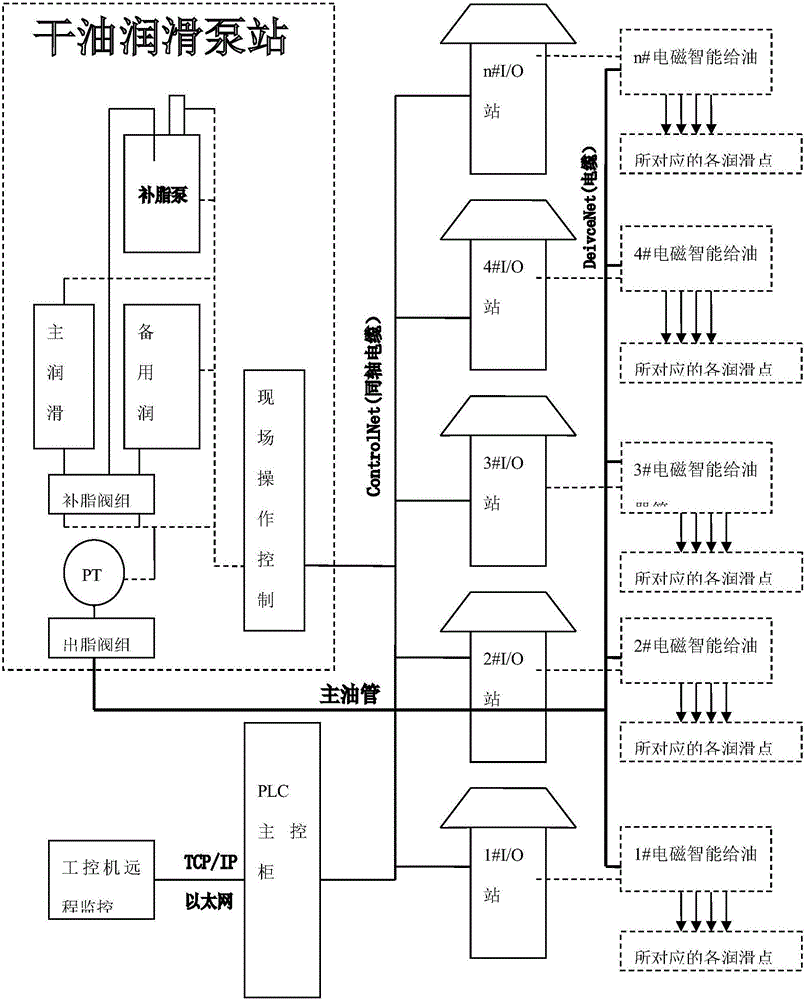

[0041] refer to figure 1 , The dry oil lubrication pump station is the power center of the all-digital intelligent dry oil lubrication system to store and pressurize dry oil grease; it provides high-pressure grease for all lubrication points of all equipment in the system.

[0042] The PLC main control system is the control center of the all-digital intelligent dry oil lubrication system; completes the real-time collection and exchange of information on the pump station and each lubrication point on site, and issues instructions to it; completes the timing and quantitative, point-to-point grease lubrication of each lubrication point of mechanical equipment and various status monitoring.

[0043] The electromagnetic intelligent oiler box is the executive mechanism of the all-digital intelligent dry oil lubrication system to supply grease to eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com