Wallboard modeling method based on UDF technology

A modeling method and siding technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as low production efficiency and poor model consistency, and achieve rapid modeling, convenient and fast operation, and large-scale research. The effect of value and practical engineering significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below with reference to the accompanying drawings and examples.

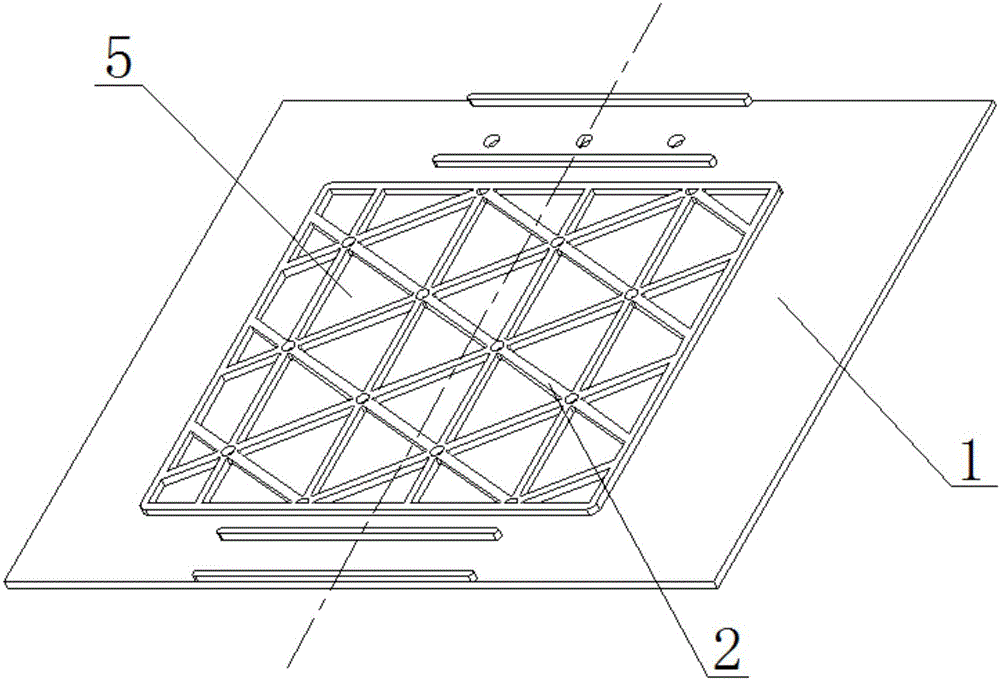

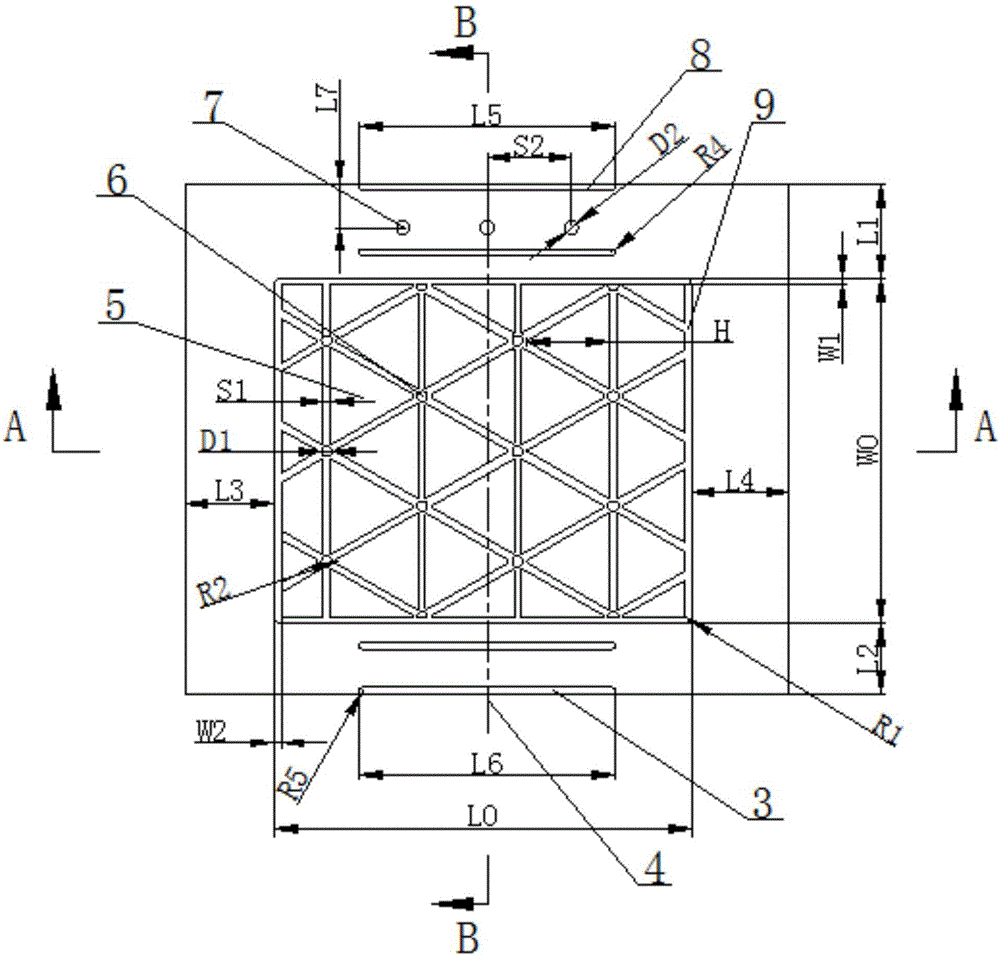

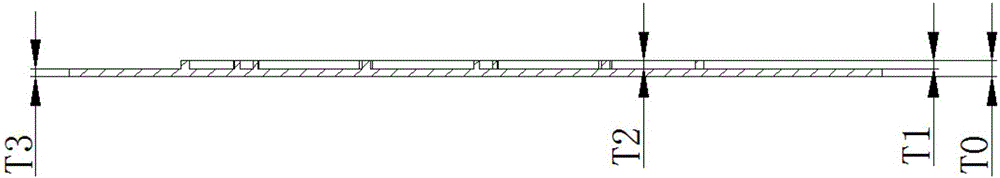

[0038] According to the modeling requirements of the panel and the geometric characteristics of the panel model, the panel is divided into margin area 1 and grid area 2. The margin area 1 is outside the grid area 2, and its structure is relatively simple, only auxiliary ribs and hoisting holes 7 are arranged symmetrically along the center line 4 of the upper surface of the margin area; while the grid area 2 has uniformly distributed grids The modeling process of unit 5 and relief hole 6 is relatively complicated.

[0039] After the division is completed, classify and analyze the structural geometric information of the panel model, including design parameters, feature dimensions, and reference dimensions, and sort out the parent-child relationship between the features included in the model and the driving relationship between parameters and dimensions .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com