Conductive composite film and its preparation and application

A technology of composite film and conductive material, applied in composite film material and its preparation and application fields, can solve the problems of poor flexibility of conductive film, complicated preparation process, poor wearable performance, etc., and achieve stable electrical performance, simple preparation process, and improved Effects of Electrical Safety and Durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

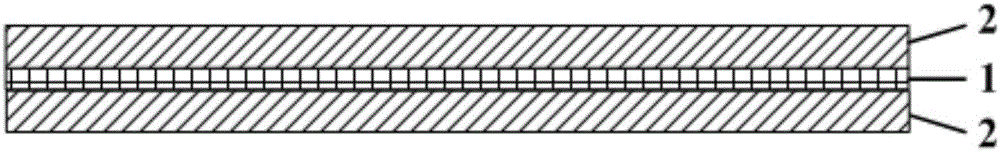

[0037] Immerse a layer of ultrathin carbon nanotube film in the graphene suspension, take it out after 3 hours of treatment, and let it dry naturally at room temperature to obtain a carbon nanotube / graphene composite film.

[0038] The carbon nanotube / graphene film that makes is put into 50mL, 1mol / L HClO 4 In the reactor of the solution, carry out magnetic stirring under ice bath, add aniline monomer (10mmol / L), after stirring for 30min, APS (6.7mmol / L) is dissolved in 5mLHClO 4 Solution and added to the reactor, keep stirring in ice bath for 24h. After the polymerization was completed, the film was taken out and treated with HClO at a concentration of 0.1 mol / L 4 The solution was rinsed, then placed in a vacuum drying oven, and dried overnight at 45° C. to obtain a carbon nanotube / graphene / polyaniline composite conductive film.

[0039] At both ends of the above composite conductive film, the copper wire electrodes are adhered with conductive silver glue, and the PDMS (pol...

Embodiment 2

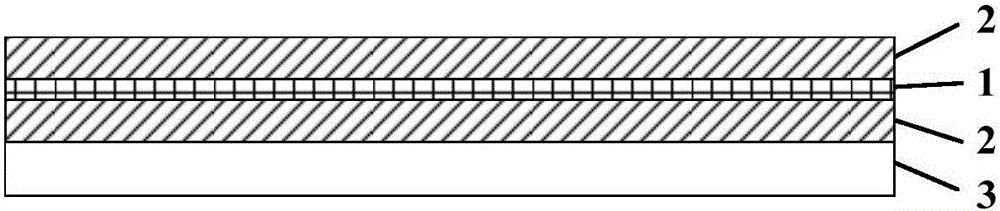

[0042] Immerse a layer of ultrathin carbon nanotube film in the graphene suspension, take it out after 3 hours of treatment, and let it dry naturally at room temperature to obtain a carbon nanotube / graphene composite film.

[0043] The carbon nanotube / graphene film that makes is put into 50mL, 1mol / L HClO 4 In the reactor of the solution, carry out magnetic stirring under ice bath, add aniline monomer (10mmol / L), after stirring for 30min, APS (6.7mmol / L) is dissolved in 5mLHClO 4Solution and added to the reactor, keep stirring in ice bath for 24h. After the polymerization was completed, the film was taken out and treated with HClO at a concentration of 0.1 mol / L 4 The solution was rinsed, then placed in a vacuum drying oven, and dried overnight at 45° C. to obtain a carbon nanotube / graphene / polyaniline composite conductive film.

[0044] At both ends of the above-mentioned composite conductive film, the copper wire electrodes are adhered by conductive silver glue, and water-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com