Construction method for heating ultra-high voltage transformer oil with low-frequency current short circuit method

A technology of transformer oil and low-frequency current, applied in the direction of transformer/inductor cooling, etc., can solve the advantages of reducing the efficiency and speed of heating transformer by short-circuit method, high working voltage of power-frequency current short-circuit heating device, complicated transportation, installation, and layout, etc. problems, to avoid long-term on-duty, shorten the heating time, and reduce the on-site workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

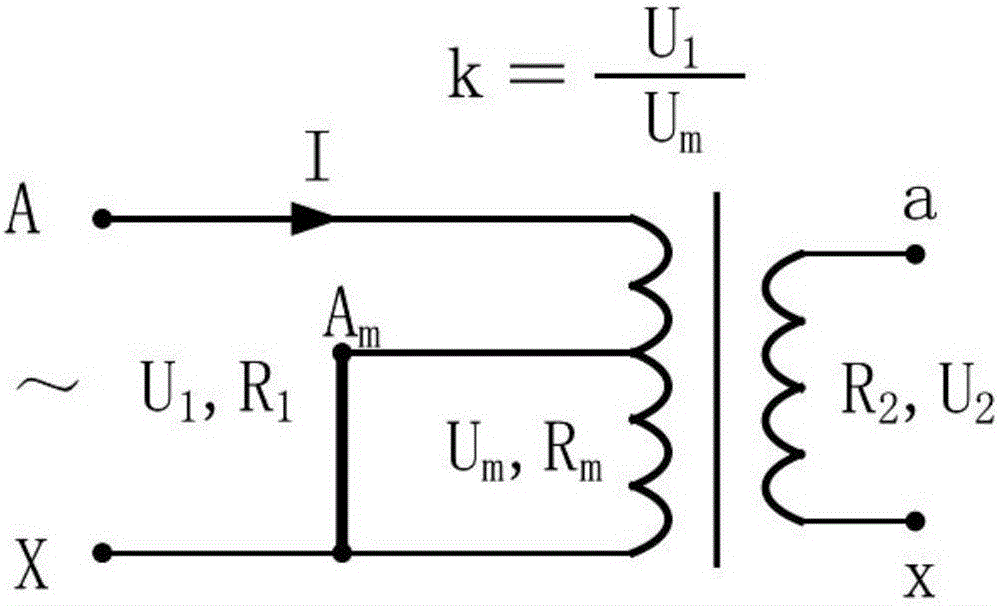

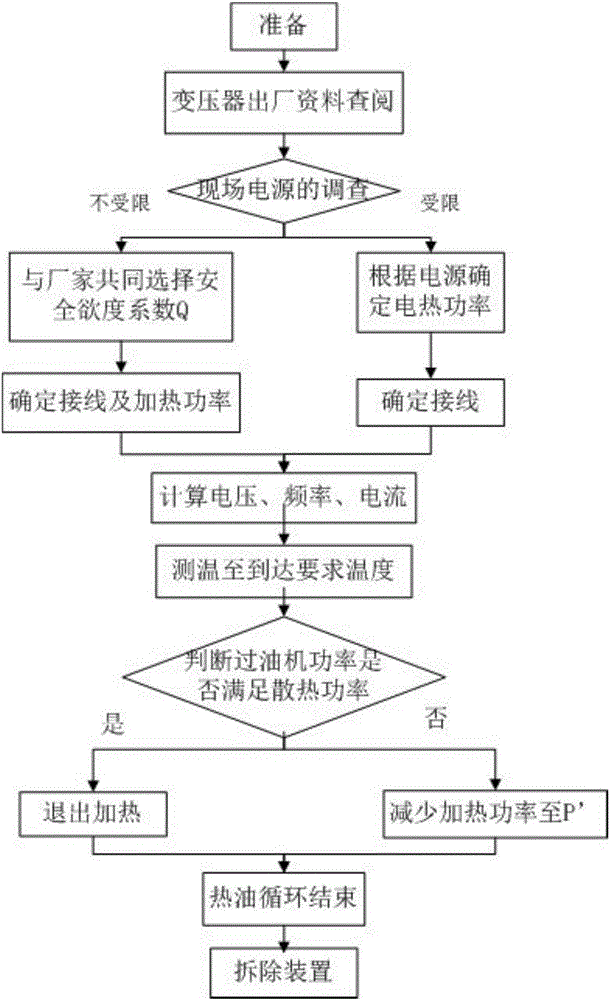

[0048] A construction method for heating ultra-high voltage transformer oil by low-frequency current short-circuit method, see attached figure 1 In the wiring method shown, the basic principle of the short-circuit method is to short-circuit the winding on one side of the converter transformer (usually the winding on the valve side), and apply an AC voltage from the winding on the other side (usually the winding on the grid side), so that current flows through the winding (should be control not to exceed its rated current), so that the inside of the winding heats up, and the insulation of the transformer body is evenly heated to the specified temperature from the inside, and then vacuumized and hot oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com