Semiconductor conic laser device

A laser and semiconductor technology, applied in the structure of optical waveguide semiconductors, can solve the problems of poor beam quality, complex fabrication, poor heat dissipation of tapered lasers, etc., and achieve the effect of reducing current density, good beam quality, and avoiding poor heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

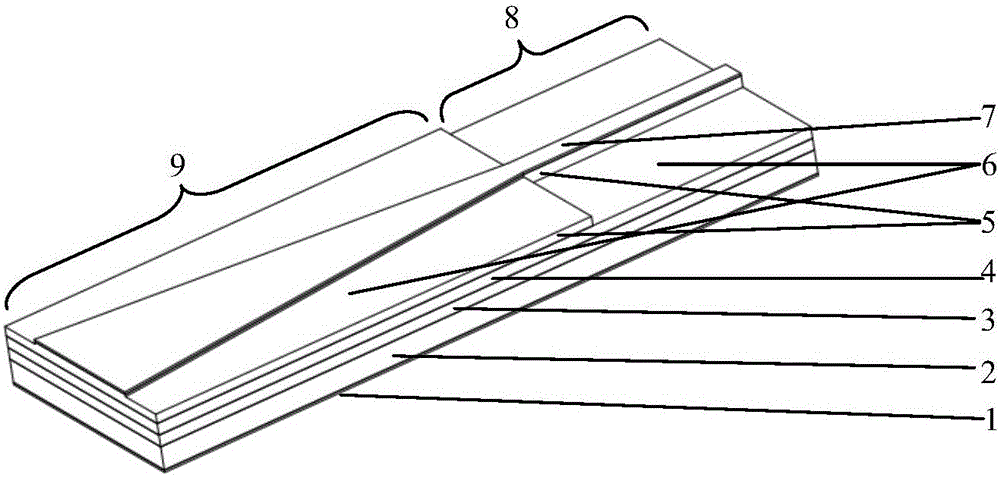

[0027] Such as figure 1 As shown, from bottom to top, it includes N-face electrode, N-face substrate, N cladding layer, confinement layer, P cladding layer, and P-face electrode. The length of the laser is 4mm and the width is 1mm. The laser is divided into a ridge area and an amplification area as a whole. The length of the ridge waveguide part is 1mm and the width is 0.005mm. The surface width is 0.32mm. The surface of the ridge waveguide is composed of ten small electrodes. The length of each electrode is 0.05mm, the width is 0.005mm, and the distance between the electrodes is 0.05mm. The layers are exactly the same.

[0028] On the planes on both sides of the electrode on the P surface, an insulating coating is provided to prevent current from directly flowing out of the substrate without passing through the active region. Wherein, the insulating plating layer in the ridge-shaped area is located on the surface of the restriction layer at the corresponding position, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com