Robot for inspection of overhead high-voltage power transmission line

A technology for high-voltage transmission lines and robots, applied in the field of robots, can solve the problems of short-distance inspection of wire towers, large damage to high-voltage lines, and difficulty in promotion, and achieve the effects of reducing wire damage, strong adaptability, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

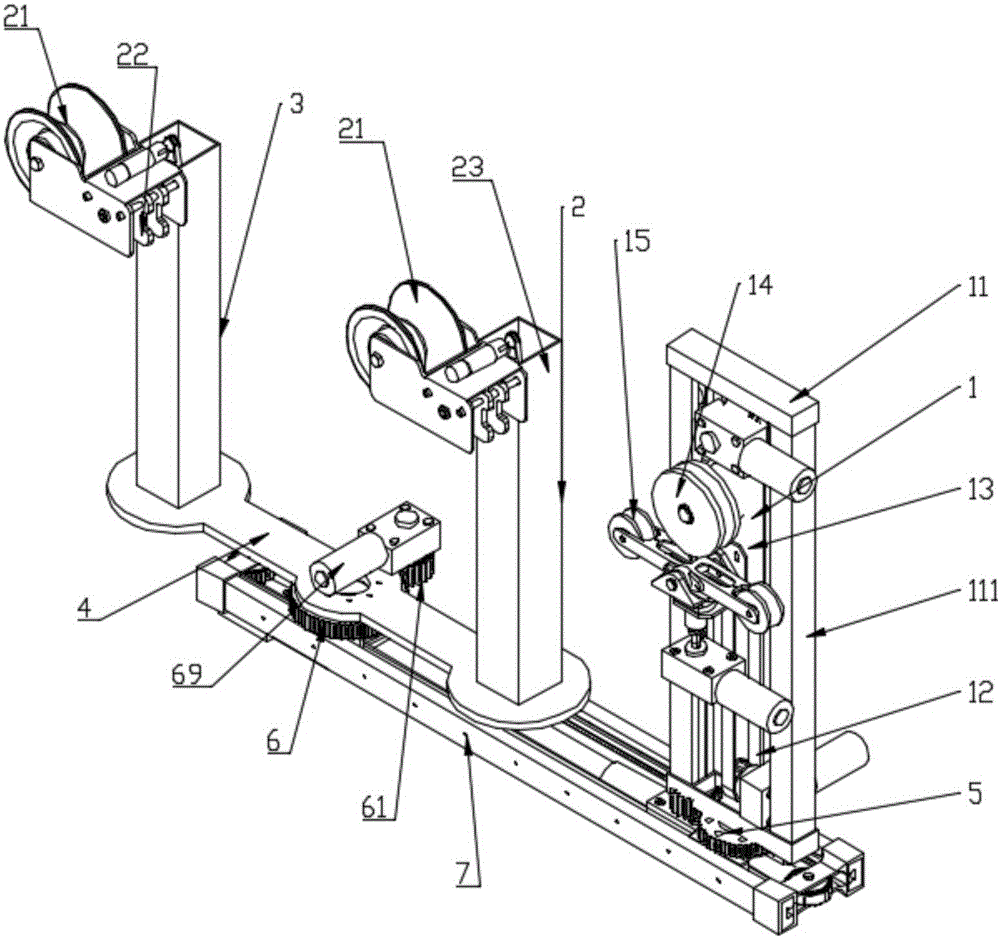

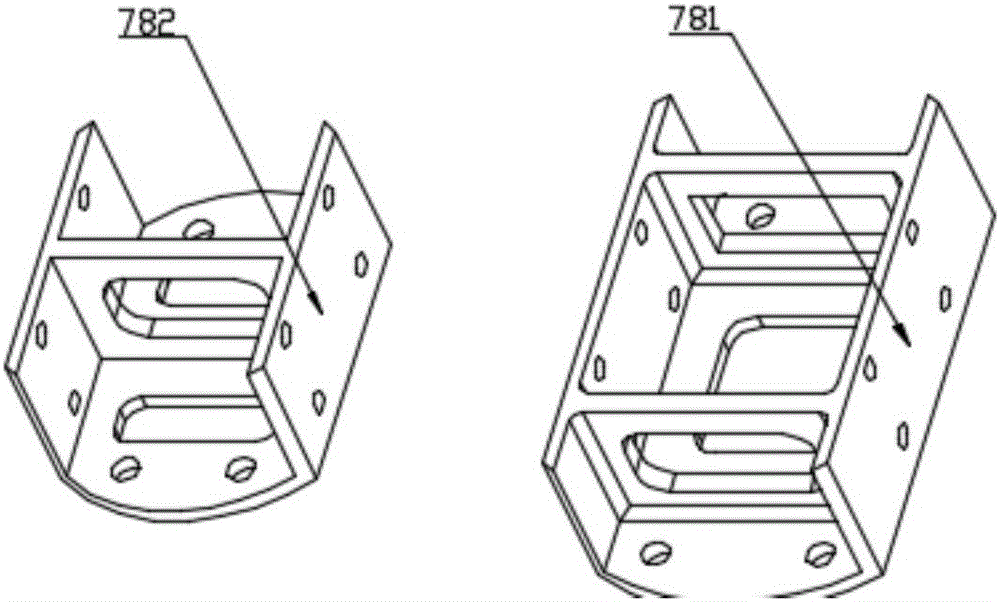

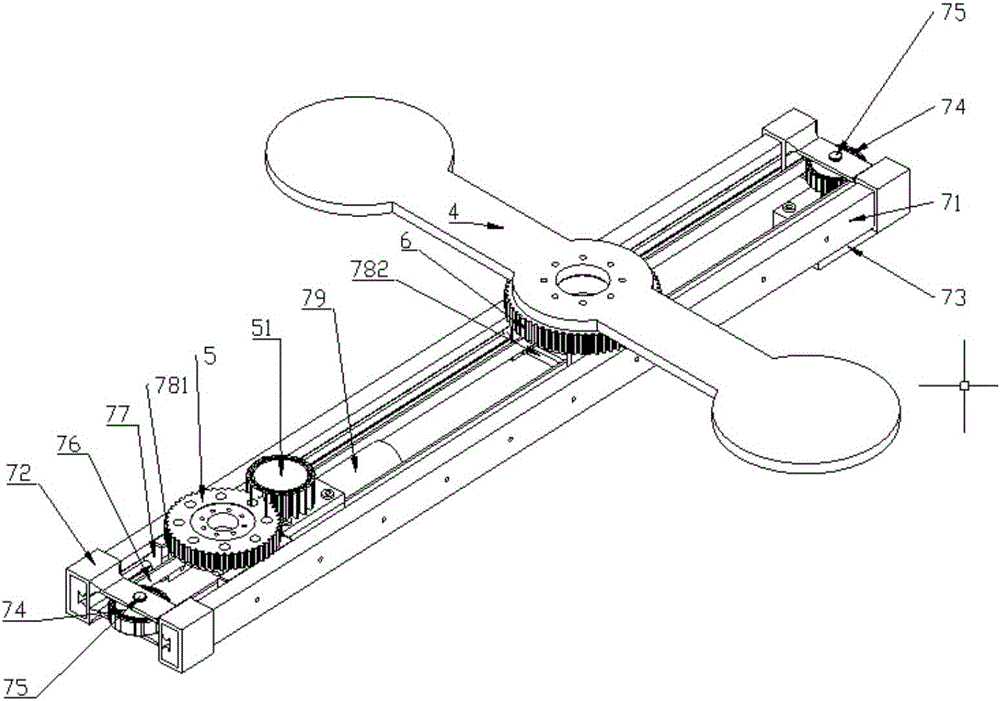

[0048] see Figure 1-8 A robot for inspection of overhead high-voltage transmission lines, including a forearm 1, a front bracket 11, a lifting main rod 111, a lifting block 12, an upper lifting synchronous pulley 121, a lifting synchronous pulley fixing frame 122, and a lifting synchronous belt 123, lower lifting synchronous pulley 124, lifting motor 125, fixing piece 126, forearm base 127, lifting platform 13, lifting platform bracket 131, cantilever shaft 132, lifting pulley assembly 133, driving wheel block 14, grooved driving wheel 141 , driving wheel shaft 142, driving wheel support 143, walking camera 144, traveling gear 145, traveling gear belt 146, pressing wheel assembly block 15, pressing motor 150, pressing wheel 151, pressing wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com