Volume kalman filter-based radial magnetic bearing displacement detection method and system

A technology of displacement detection and magnetic bearing, which is applied in the direction of control system, vector control system, control electromechanical brake, etc. It can solve the problems of restricting the maximum speed of magnetic bearing, affecting the reliable operation of the control system, and poor detection accuracy and real-time performance of magnetic bearing displacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

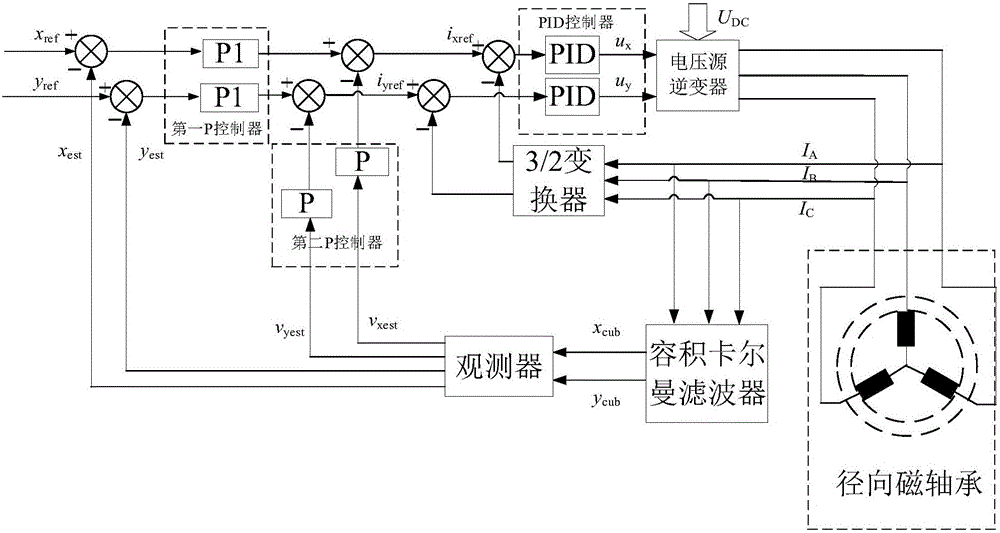

[0043] Such as figure 1 As shown, this embodiment 1 provides a method for constructing a continuous-time system for radial magnetic bearing displacement detection, including the following steps:

[0044] Step S1, calculating the levitation force on the rotor in the directions of the three magnetic poles;

[0045] Step S2, establishing a continuous time system.

[0046] Specifically, the method for calculating the levitation force on the rotor in the direction of the three magnetic poles in the step S1 includes:

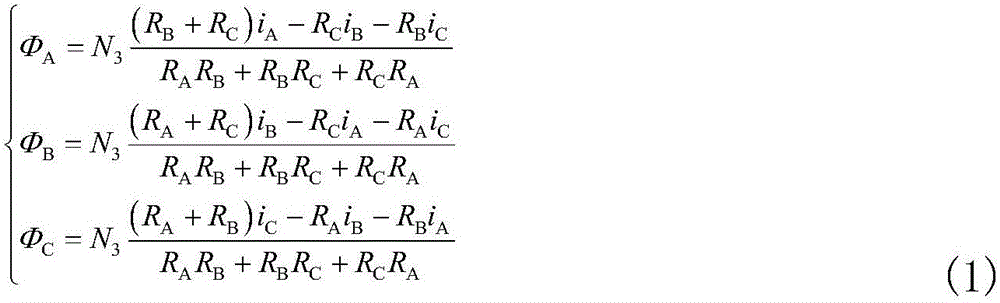

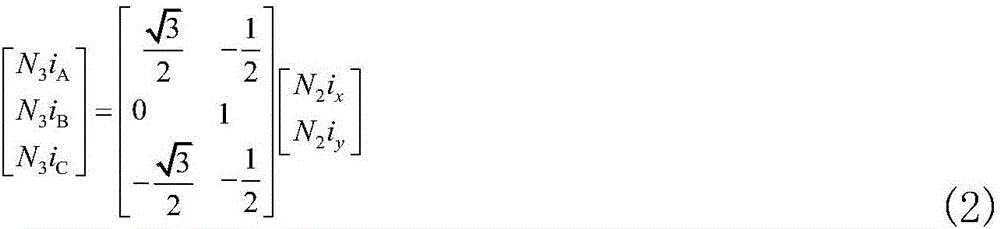

[0047] Step S11, calculate the magnetic flux of the air gap of each magnetic pole, which is shown in formula (1):

[0048] Φ A = N 3 ( R B ...

Embodiment 2

[0094]On the basis of Embodiment 1, Embodiment 2 provides a radial magnetic bearing displacement detection method, including:

[0095] According to the continuous time system, the radial displacement output signal and rotational speed signal of the rotor in the x and y directions are obtained, and the continuous time system is discretized to realize the volumetric Kalman filter algorithm to extract the displacement information of the rotor.

[0096] Wherein, the method for extracting the displacement information of the rotor by the volumetric Kalman filter algorithm includes: generating the current I by the volumetric Kalman filter according to the voltage source inverter A , I B , I C Extracted current signal x cub and y cub , and obtain the displacement output signal x of the radial magnetic bearing in the x and y directions through the observer est and y est , where the displacement output signal x est and y est It also represents the displacement information of the ...

Embodiment 3

[0100] On the basis of Embodiment 1, Embodiment 3 provides a displacement detection method for a radial magnetic bearing.

[0101] The radial magnetic bearing displacement detection method includes: building a feedback loop through a volumetric Kalman filter to adjust the current generated by the voltage source inverter to drive the magnetic bearing to achieve closed-loop stable suspension.

[0102] Specifically, a feedback loop is constructed through a volumetric Kalman filter, namely

[0103] The current I is generated by the volumetric Kalman filter according to the voltage source inverter A , I B , I C Extracted current signal x cub and y cub , and obtain the displacement output signal x of the radial magnetic bearing in the x and y directions through the observer est and y est , with a given reference position signal x ref and y ref For comparison, after the obtained result is processed by the first P controller, it is respectively compared with the speed signal v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com