Surface false-patch quartz crystal resonator having grounding welding spot and processing method thereof

A technology of quartz crystal and processing method, which is applied to electrical components, impedance networks, etc., can solve the problems of uncertainty in the directionality of the third lead wire of the quartz crystal resonator resonator, affecting the frequency of the resonator, and complex processing technology. The effect of improving product frequency stability, reducing raw material cost, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] In this embodiment, an insulating gasket with one side opening and a mask net are selected to process the quartz crystal resonator, and the specific steps are as follows:

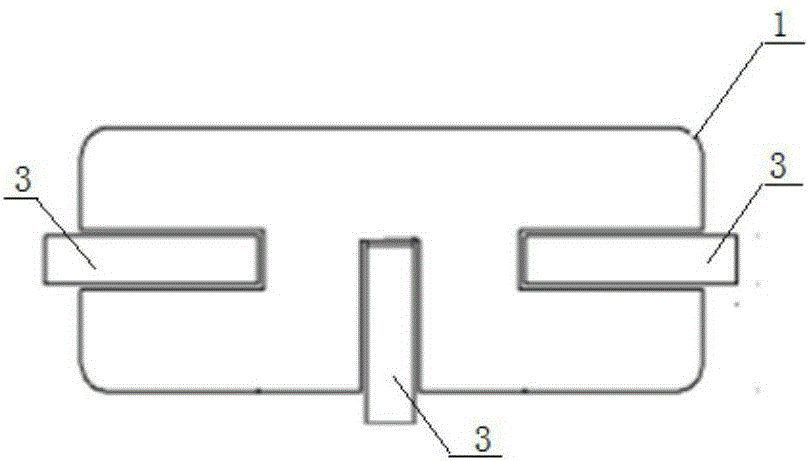

[0055] Step 1. Process the quartz crystal resonator into a surface-mounted quartz crystal resonator with two leads: insert an insulating gasket with one side opening on the quartz crystal resonator, extend a lead wire from each through hole, and Bending to both sides, exposed on the bottom plate of the quartz crystal resonator corresponding to the opening on one side;

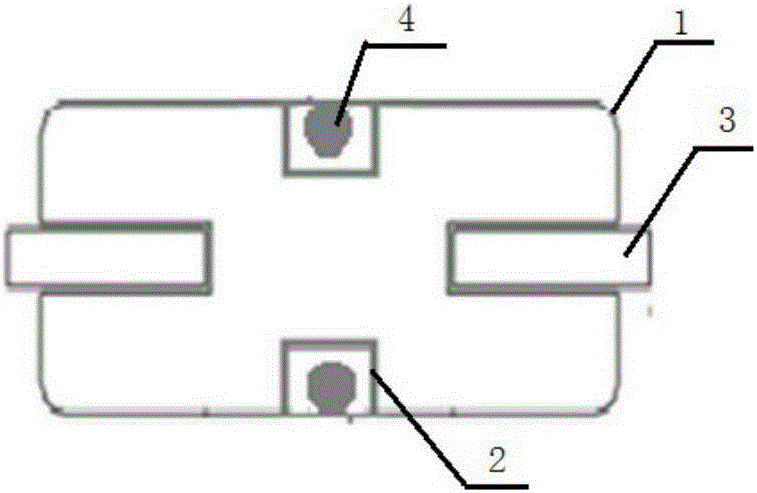

[0056] Step 2. Put the surface-mounted quartz crystal resonator processed in step 1 into the test disk, test whether the quartz crystal resonator processed into two leads is qualified, remove unqualified products, and fill the test disk until further After processing qualified products, cover the mask sheet above the test disc; the hollow on the mask sheet used in this embodiment corresponds to the opening on one side of the insulatin...

Embodiment 2

[0061] In this embodiment, the steps of processing are similar to Embodiment 1, and the insulating gasket and the mask net with double-sided openings are selected to process the quartz crystal resonator. In the present embodiment, in the direction of the length of the insulating gasket, the There are openings on both sides, and the areas corresponding to the openings on both sides of the bottom plate of the quartz crystal resonator are exposed, and the structure of the mask is also adjusted so that the hollows on the mask correspond to the positions of the openings on both sides on the insulating gasket.

[0062] The specific processing steps of the present embodiment are:

[0063] Step 1. Process the quartz crystal resonator into a surface-mounted quartz crystal resonator with two leads: insert insulating gaskets with double-sided openings on the quartz crystal resonator, extend a lead wire from each through hole, and Bend to both sides, exposed on the bottom plate of the qua...

Embodiment 3

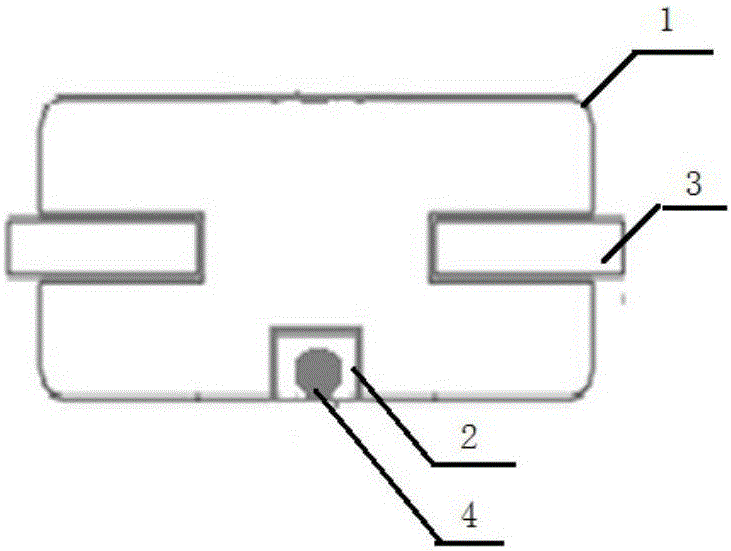

[0069] In this embodiment, the processing steps are similar to that of Embodiment 1, and the insulating gasket with one side opening is selected. The difference from Embodiment 1 is that the shielding plate of this embodiment is selected from steel mesh, and the solder is metal paste; Corresponds to the opening position on one side of the insulating spacer.

[0070] The concrete process of this embodiment is:

[0071] Step 1. Process the quartz crystal resonator into a surface-mounted quartz crystal resonator with two leads: insert an insulating gasket with one side opening on the quartz crystal resonator, extend a lead wire from each through hole, and Bending to both sides, exposed on the bottom plate of the quartz crystal resonator corresponding to the opening on one side;

[0072] Step 2. Put the surface-mounted quartz crystal resonator processed in step 1 into the test disk, test whether the quartz crystal resonator processed into two leads is qualified, remove unqualifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com