Kitchen biogas slurry treatment method and device

A technology for biogas slurry treatment and kitchen, which is applied in separation methods, water/sewage treatment, chemical instruments and methods, etc. It can solve the problems of inability to meet the discharge standards and poor biodegradability, so as to save the cost of chemicals and reduce the dosage of chemicals , The effect of short engineering cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

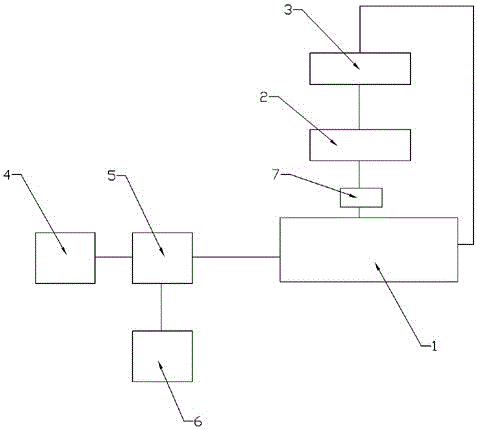

[0025] Such as figure 1 As shown, a kitchen biogas slurry treatment device includes a pretreatment part, an MVR evaporator 1, a primary steam purifier 2 and a secondary steam purifier 3, and the pretreatment part and the MVR evaporator 1 The water inlets are connected, the MVR evaporator 1, the primary steam purifier 2 and the secondary steam purifier 3 are connected in sequence, and the secondary steam purifier 3 is connected to the MVR evaporator 1 connected, the pretreatment part is connected with the external biogas digester.

[0026] The pretreatment section includes a mixer 4, a sedimentation tank 5 and a dehydrator 6 connected in sequence, the water inlet of the mixer 4 is connected to an external biogas slurry tank, and the water outlet of the sedimentation tank 5 is connected to the MVR The first water inlet of the evaporator 1 is connected, and the outlet of the sedimentation tank 5 is connected with the inlet of the dehydrator 6 .

[0027] A demister 7 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com