a smokeless boiler

A boiler and flue technology, which is applied in the field of smokeless boilers, can solve the problems of affecting combustion efficiency, dealing with ash and dust, and difficulty in cleaning, so as to improve combustion efficiency and avoid dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiment given below intends to further illustrate the present invention, but can not be interpreted as the restriction to protection scope of the present invention, those skilled in the art still belongs to the protection of the present invention to some non-essential improvements and adjustments of the present invention according to the content of the present invention scope.

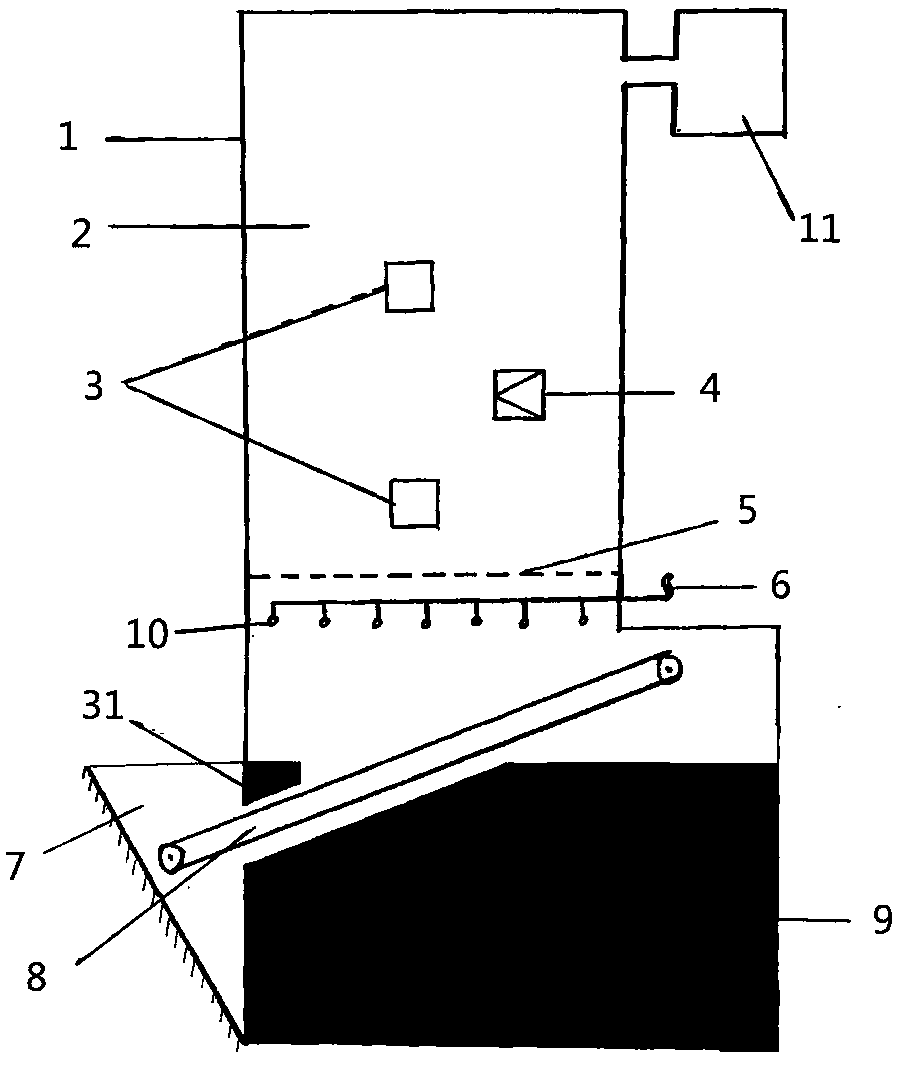

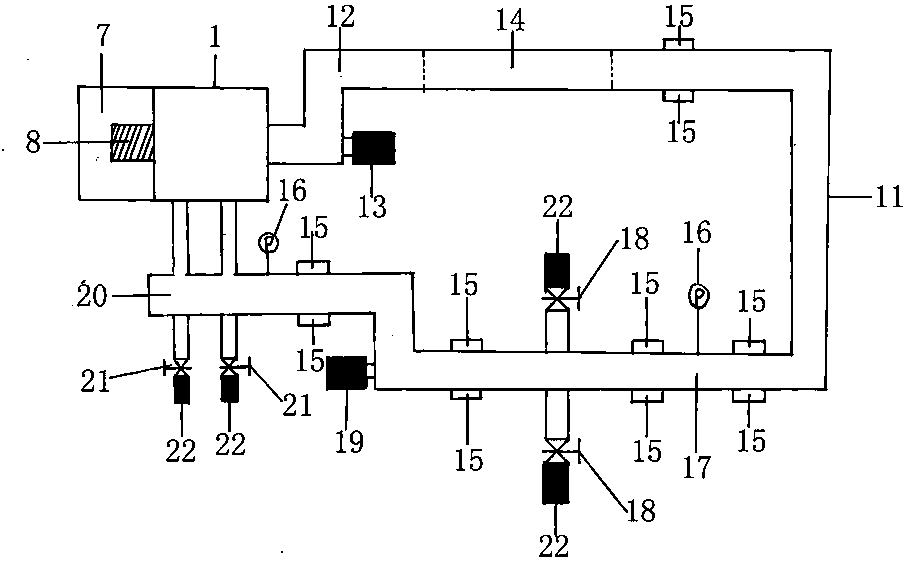

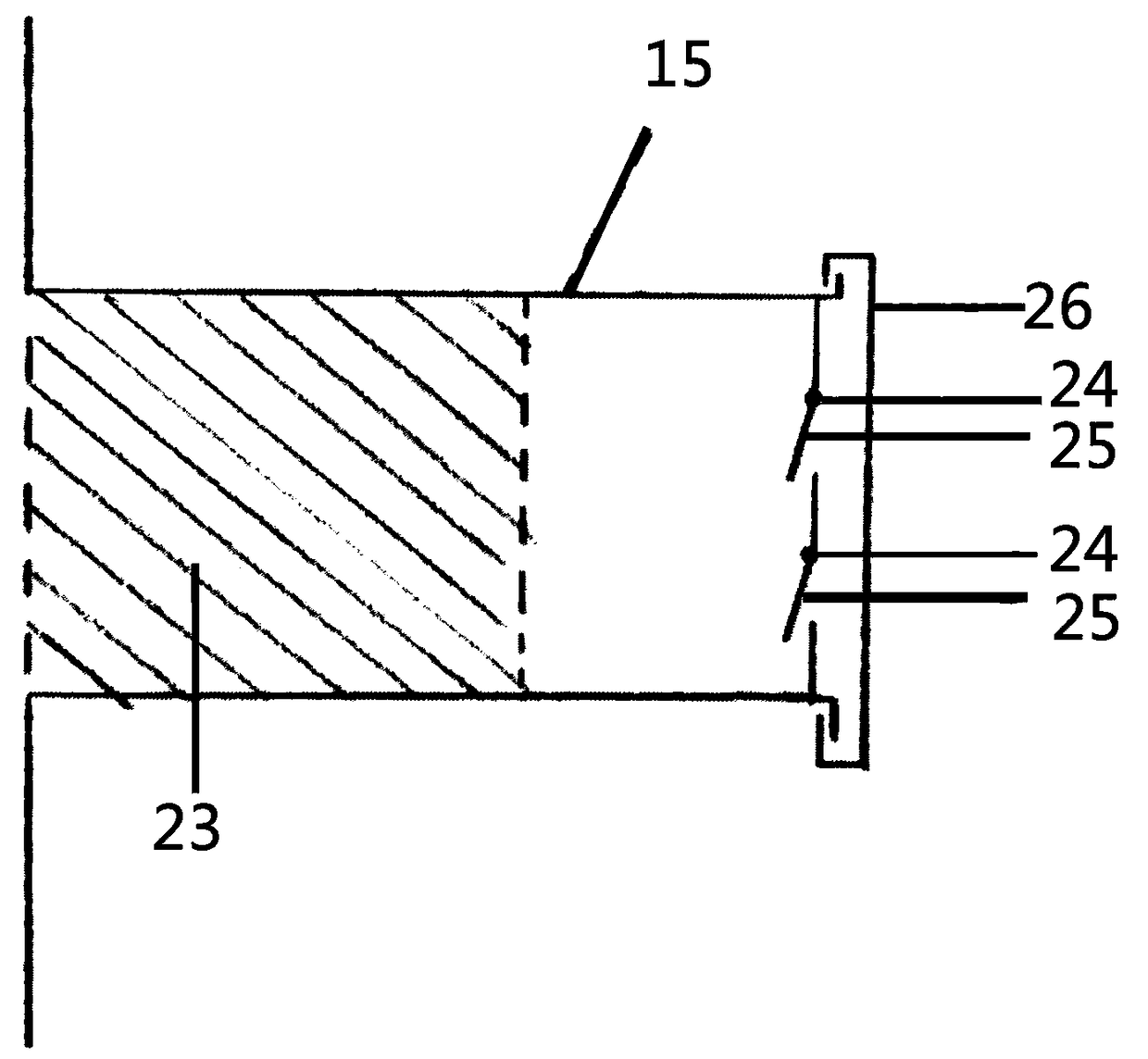

[0031] A smokeless boiler of the present invention comprises: 1. Boiler furnace body, 2. Combustion chamber, 3. Fire sight glass, 4. Filling port, 5. Furnace bar, 6. Damper, 7. Pool, 8. Ash conveyor belt , 9. Furnace pit enclosure, 10. Air inlet, 11. Flue, 12. Outlet, 13. Outlet blower, 14. Smoke eliminator, 15. Air supply, 16. Barometer, 17 .Return air duct, 18. Return air release valve, 19. Intake duct blower, 20. Intake duct, 21. Intake pressure relief valve, 22. Air filter, 23. Filter element, 24. Rotary shaft, 25. Air supply baffle, 26. Air supply protection cover, 27. Inlet baffle,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com