Production method of quickly-fermented high-umami seafood fermented soybean sauce

A technology for soy sauce and seafood, applied in the field of food processing, can solve the problems of waste of biological resources, pollute the environment, short production cycle, etc., and achieve the effects of short production cycle, good quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

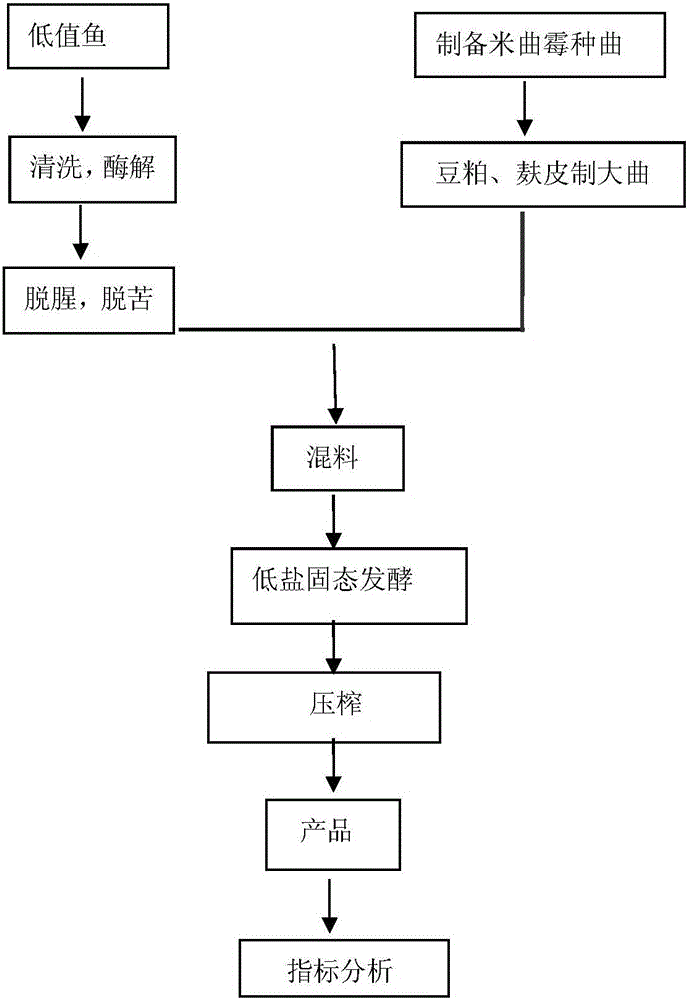

Method used

Image

Examples

Embodiment 1

[0044] A preparation method of seafood fermented soy sauce with outstanding umami taste of rapid fermentation, the steps are as follows:

[0045] (1) Soaking: 600g of soybean meal, 400g of bran, mixed with 1100mL of water, weigh the soybean meal and add a certain amount of warm water (80°C), cover it with bran, soak for 30min, stir well, and get the mixed raw material, place it in the koji High temperature sterilization on cloth for use;

[0046] (2) Sterilization: take 500g of mixed wet material, put it in an autoclave, and sterilize at 121°C for 20 minutes;

[0047] (3) Koji making: After the material is cooled to 35°C, 500g of koji material is inoculated with 1.5g of Aspergillus oryzae seed koji (500g of wet material is placed in each koji box, and the thickness cannot exceed 2cm), fully mixed evenly, and the mixed material after inoculation, Carry out stacking culture in a constant temperature incubator at 32°C. After 12 hours of cultivation, turn the song for the first t...

Embodiment 2

[0056] A preparation method of seafood fermented soy sauce with outstanding umami taste of rapid fermentation, the steps are as follows:

[0057] (1) Soaking: 700g of soybean meal, 300g of bran, mixed with 1000mL of water, weigh the soybean meal into a basin, add a certain amount of warm boiled water (90°C), cover it with bran, soak for 20min, and stir well to obtain the mixed raw material , placed on a bent cloth for high-temperature sterilization;

[0058] (2) Sterilization: Take 500g of the mixed wet material and put it on the cloth, and put it in an autoclave at the same time, and sterilize it at 121°C for 15min-20min;

[0059] (3) Koji making: After the material is cooled to 25°C, inoculate 1.5g to 2.5g of Aspergillus oryzae seed koji with 500g of koji material (500g of wet material in each koji box, and the thickness cannot exceed 2cm), mix well, and inoculate the koji The mixed material is placed in a constant temperature ventilated incubator, and stacked in a 30°C con...

Embodiment 3

[0068] A method for preparing seafood fermented soy sauce with rapid fermentation and outstanding umami taste. The preparation method utilizes high-efficiency biological enzymolysis to prepare a small molecule enzymatic solution, and co-ferments the small molecule enzymatic solution with soybean meal and bran to prepare seafood fermented soy sauce.

[0069] Specific steps are as follows:

[0070] (1) Soaking: According to the mass ratio of soybean meal: bran is 6:4 or 7:3, take the raw soybean meal and bran, mix the water with 100%-110% of the total mass of the whole material, weigh the soybean meal and put it into the pot Add a certain amount of warm boiled water (80°C~90°C), cover it with bran, soak for 30min~35min, stir evenly to obtain mixed raw materials, put them on a bent cloth for high temperature sterilization for later use;

[0071] (2) Sterilization: Place the mixed raw materials in an autoclave, and sterilize at 121°C for 15min to 20min;

[0072] (3) Koji making: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com