Methods of separating gases

一种分离气体、膜分离的技术,应用在分离方法、气体燃料、气体处理等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Example 1: Separation of a mixture of methane and carbon dioxide with a 50:50 mixing ratio using a highly selective polyimide membrane

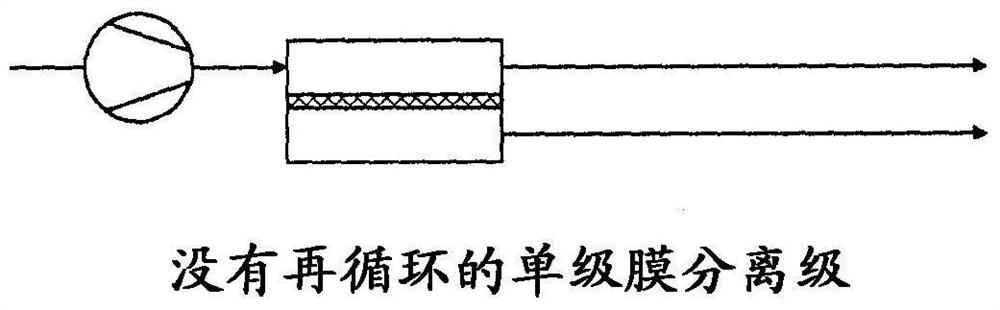

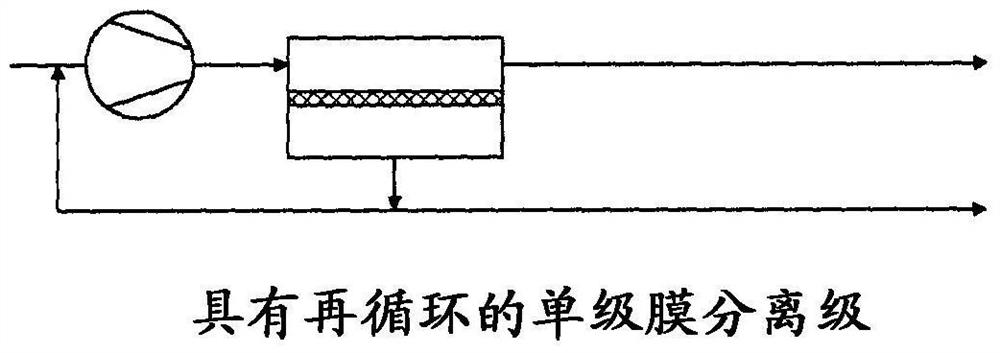

[0079] use Figure 11 connection shown. Each stage consists of a hollow fiber membrane module consisting of approximately 5 m 2 A highly selective hollow polyimide fiber for the separation area of the component is constructed. These hollow polyimide fibers were prepared according to example 19 of Austrian patent application A1164 / 2009, but where the operation was performed with a precipitation bath temperature of 40°C instead of 10°C. will 1m 3 A crude gas mixture of 50% methane and 50% carbon dioxide per hour, which roughly corresponds to the gas mixture of biogas, was introduced into the mixing chamber and then compressed to 25 bar together with the recycle gas consisting of gas streams 9 and 10 . The gas that has been compressed and cooled to 20° C. is applied to the feed stream separation stage 1 . The retentate of this stag...

Embodiment 2

[0081] Example 2: Separation of a mixture of methane and carbon dioxide with a mixing ratio of 50:50 with a highly selective polyimide membrane at a methane content of less than 0.5% in the permeate stream

[0082] In order to meet various legislator requirements, methane losses into the atmosphere must be kept as low as possible. use Figure 11 The connections shown are to reduce the concentration of methane in the third permeate stream 11 to less than 0.5% by volume. Each stage consists of a hollow fiber membrane module consisting of approximately 5 m 2 A highly selective polyimide composition for the separation area / components. These hollow polyimide fibers were prepared according to example 19 of Austrian patent application A1164 / 2009, but where the operation was performed with a precipitation bath temperature of 40°C instead of 10°C. will 1m 3A crude gas mixture of 50% methane and 50% carbon dioxide per hour, which roughly corresponds to the gas mixture of biogas, was...

Embodiment 3

[0084] Example 3: Separation of methane and carbon dioxide with a 50:50 mix by means of a vacuum pump for the permeate of stage 2 with a highly selective polyimide membrane with a methane content of less than 0.5% in the permeate stream mixture of ratios

[0085] In order to meet various legislator requirements, the loss of methane into the atmosphere must be kept as small as possible. use Figure 11 Connections shown (supplemented with Figure 11 vacuum pump not shown) to reduce the concentration of methane in the third permeate stream 11 to less than 0.5% by volume. Each stage consists of a hollow fiber membrane module consisting of approximately 5 m 2 A highly selective hollow polyimide fiber for the separation area of the component is constructed. These hollow polyimide fibers were prepared according to example 19 of Austrian patent application A1164 / 2009, but where the operation was performed with a precipitation bath temperature of 40°C instead of 10°C. will 1m 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volumetric flow rate | aaaaa | aaaaa |

| volumetric flow rate | aaaaa | aaaaa |

| volumetric flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com