Three-dimensional lattice material based on electron beam selective melting technology and preparation method of three-dimensional lattice material based on electron beam selective melting technology

A three-dimensional lattice and selective melting technology, which is applied in the direction of additive manufacturing, process efficiency improvement, and energy efficiency improvement, can solve problems such as adjustment of unit cell structure, poor repeatability of material performance, and inability for designers to provide mechanical performance parameters. Achieve the effect of stable and reliable calculation basis and stable compression performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

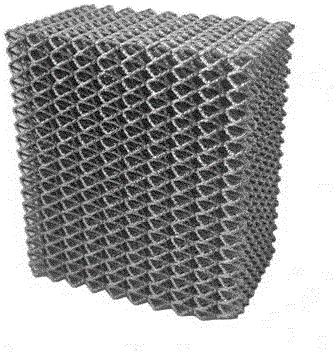

[0038] The three-dimensional lattice material based on electron beam selective melting technology in this embodiment includes a three-dimensional structure formed by superimposing a plurality of basic units. The basic unit is composed of a plurality of isosceles triangles. coincide, the waist of the isosceles triangle is a solid rod body, the rest of the isosceles triangle is a virtual body, and there is a waist overlap between two adjacent isosceles triangles; the material of the three-dimensional structure is Titanium or titanium alloys.

[0039] In this embodiment, the material of the three-dimensional structure is Ti-6Al-4V titanium alloy.

[0040] In this embodiment, the length L of the solid rod body is 3.0 mm, the cross-sectional shape of the solid rod body is circular, the equivalent diameter d of the solid rod body cross-section is 0.3 mm, and the solid rod body is melted with electron beam selection The angle θ between the deposition faces is 36°. Such as Figure 7 ...

Embodiment 2

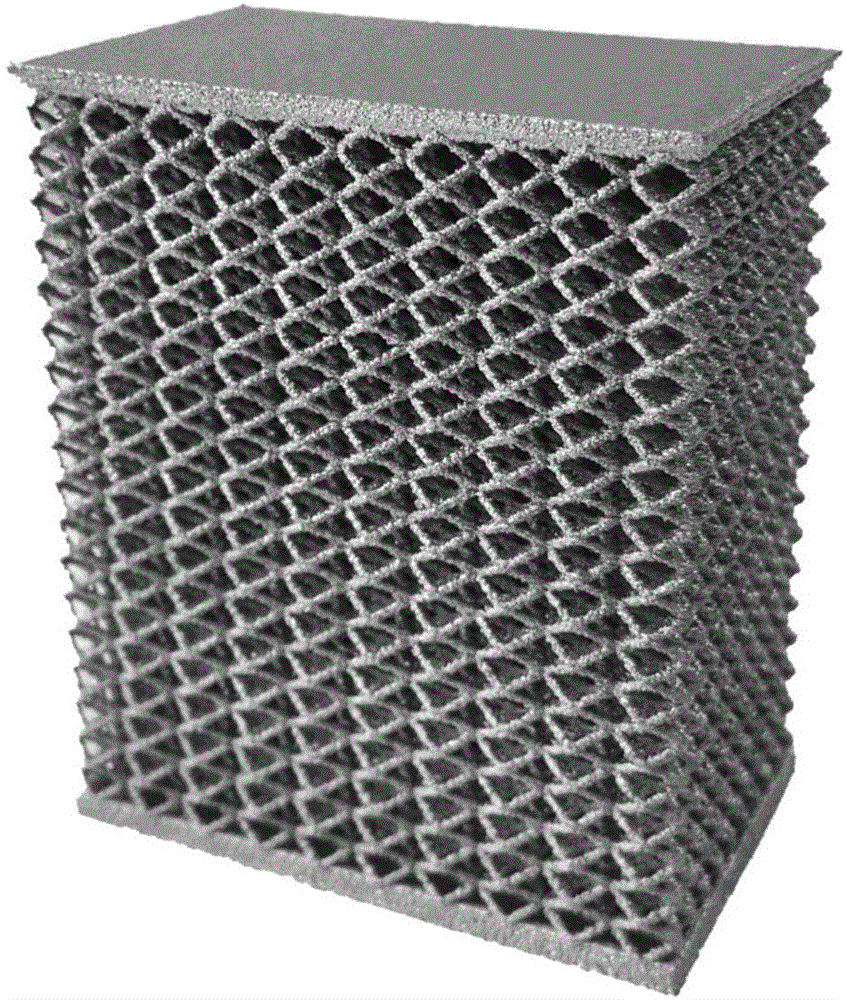

[0053] In this embodiment, the three-dimensional lattice material based on electron beam selective melting technology includes a three-dimensional structure composed of a plurality of basic units superimposed, and dense plates are arranged on the upper and lower parts of the three-dimensional structure, and the basic unit is composed of multiple isosceles triangles, the apexes of multiple isosceles triangles overlap, the waist of the isosceles triangles is a solid rod, the rest of the isosceles triangles are phantoms, and between two adjacent isosceles triangles is a solid body. There is a waist overlap between them; the materials of the three-dimensional structure and the dense panel are pure titanium or titanium alloy.

[0054] In this embodiment, the material of the three-dimensional structure and the dense panel is Ti-6Al-4V titanium alloy.

[0055] In this embodiment, the length L of the solid rod body is 2.7 mm, the cross-sectional shape of the solid rod body is a regula...

Embodiment 3

[0068] The three-dimensional lattice material based on electron beam selective melting technology in this embodiment includes a three-dimensional structure formed by superimposing a plurality of basic units. The basic unit is composed of a plurality of isosceles triangles. coincide, the waist of the isosceles triangle is a solid rod body, the rest of the isosceles triangle is a virtual body, and there is a waist overlap between two adjacent isosceles triangles; the material of the three-dimensional structure is Titanium or titanium alloys.

[0069] In this embodiment, the material of the three-dimensional structure is Ti-6Al-4V titanium alloy.

[0070] In this embodiment, the length L of the solid rod body is 20 mm, the cross-sectional shape of the solid rod body is a regular octagon, the equivalent diameter d of the solid rod body cross-section is 5.0 mm, and the solid rod body is melted with electron beam selection The angle θ between the deposition faces is 45°. Such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com