Welding wire winding machine capable of automatically controlling lag angles

A technology of layer winding machine and lag angle, applied in the field of welding wire layer winding machine with automatic control of lag angle, can solve the problems of difficulty in precise control of lag angle and wide diameter range of welding wire, etc. changing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

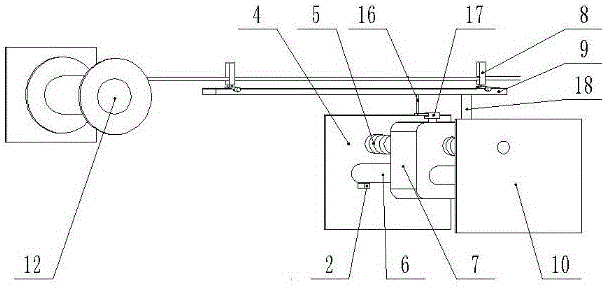

[0032] A welding wire layer winding machine with automatic control of lagging angle. like figure 1 and image 3 As shown, the welding wire layer winding machine is composed of a control system, a wire arranging mechanism and a wire take-up mechanism; the wire take-up mechanism and the wire arranging mechanism are arranged in parallel, and the wire take-up mechanism is located directly in front of the wire arranging mechanism.

[0033] like figure 1 As shown, the wire take-up mechanism is composed of a first frequency conversion motor 1 and a wire winding reel 12, and the first frequency conversion motor 1 is axially connected with the wire winding reel 12 through a shaft coupling.

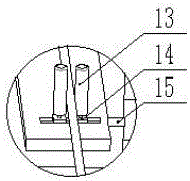

[0034] like figure 1 and image 3 As shown, the cable arrangement mechanism includes a second variable frequency motor 3 , a lead screw 5 , two guide rods 6 , a moving platform 7 and a swinging strip plate 9 . The body of mobile platform 7 is square, and described body has two through holes ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com