Low temperature and low pressure countercurrent leaching method for tellurium in copper anode slime

A copper anode slime, countercurrent leaching technology, applied in the direction of element selenium/tellurium, process efficiency improvement, etc., can solve the problems of limited promotion and application, poor operating conditions, low tellurium recovery rate, etc., to reduce cycle accumulation and increase economy Benefit, solve the effect of low tellurium removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

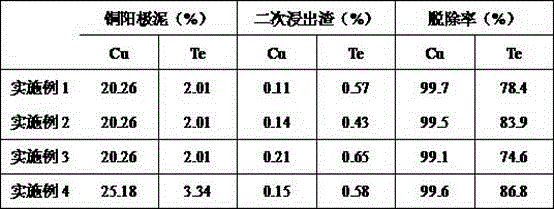

Embodiment 1

[0025] The copper anode slime treated in this example contains Cu20.26% and Te2.01%. The treatment process and treatment effect are as follows:

[0026] (1) Wash the copper anode slime in a washing tank, the liquid-solid ratio is 4:1 by volume to mass ratio L / Kg, the temperature is 30°C, and the time is 0.8h; the washing slag contains 14.5% copper and 2.25% tellurium.

[0027] (2) Put the water-washed slag in the reaction kettle for one oxygen pressure acid leaching to remove copper, control the liquid-solid ratio by volume to mass ratio L / Kg to 5:1, the acidity of sulfuric acid is 200g / L, the temperature is 100°C, and the oxygen partial pressure is 1.2 MPa, time 0.5h; primary leaching slag contains 5.22% copper and 1.85% tellurium.

[0028] (3) Put the primary leaching residue in an autoclave for secondary leaching, control the liquid-solid ratio by volume to mass ratio L / Kg to 10:1, sulfuric acid acidity 200g / L, temperature 180°C, oxygen partial pressure 0.8MPa, time 1.5 h;...

Embodiment 2

[0031] The copper anode slime treated in this example contains Cu20.26% and Te2.01%. The treatment process and treatment effect are as follows:

[0032] (1) Wash the copper anode slime in a washing tank with a liquid-solid ratio of 5:1 by volume to mass ratio L / Kg at a temperature of 40°C for 0.5 hours; the washing slag contains 12.91% copper and 2.41% tellurium.

[0033] (2) Put the water-washed slag in the reaction kettle for oxygen pressure acid leaching to remove copper, control the liquid-solid ratio according to the volume and mass ratio L / Kg to 7:1, the acidity of sulfuric acid is 150g / L, the temperature is 120°C, and the oxygen partial pressure is 1MPa , time 1h; the first leaching slag contains 4.18% copper and 1.97% tellurium.

[0034] (3) Put the primary leaching residue in an autoclave for secondary leaching, control the liquid-solid ratio by volume to mass ratio L / Kg to 15:1, sulfuric acid acidity 250g / L, temperature 160°C, oxygen partial pressure 1.2MPa, time 1h ...

Embodiment 3

[0037] The copper anode slime treated in this example contains Cu20.26% and Te2.01%. The treatment process and treatment effect are as follows:

[0038] (1) Put the copper anode slime in the washing tank for washing, the liquid-solid ratio is 3:1 according to the volume-to-mass ratio L / Kg, the temperature is 50°C, and the time is 1h; the washing slag contains 15.27% copper and 2.17% tellurium.

[0039] (2) Put the water-washed slag in the reaction kettle for one oxygen pressure acid leaching to remove copper, control the liquid-solid ratio by volume to mass ratio L / Kg to 10:1, the acidity of sulfuric acid is 100g / L, the temperature is 130°C, and the oxygen partial pressure is 0.5 MPa, time 1.5h; primary leaching slag contains 4.76% copper and 1.59% tellurium.

[0040] (3) Put the primary leaching residue in an autoclave for secondary leaching, control the liquid-solid ratio by volume to mass ratio L / Kg to 8:1, sulfuric acid acidity 150g / L, temperature 120°C, oxygen partial pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com