Hollow ball with ball wall made from composite material and layer-by-layer coating method for manufacturing hollow ball

A composite material and hollow sphere technology, applied in the field of hollow spheres, can solve the problems of reduced work efficiency, scrapped finished products, increased scrapping rate, etc., and achieve the effects of reducing scrapping rate, good energy absorption, and good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

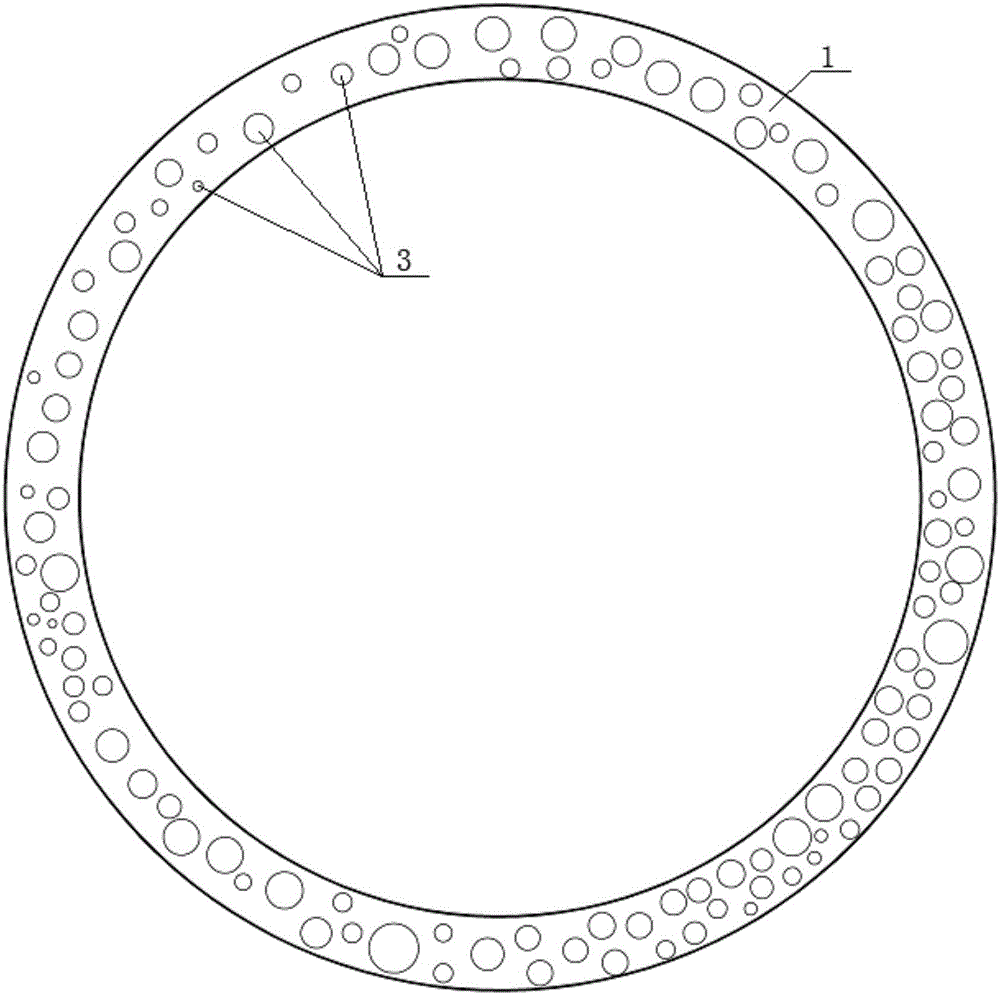

[0030] Such as figure 1 Shown: a hollow ball with a composite material as the wall, including a ball wall layer 1 filled with hollow glass microspheres 3 .

[0031] Further, the ball wall layer 1 is made of thermosetting polymer.

[0032] Further, the thermosetting polymer may be thermosetting epoxy resin, thermosetting polyimide or thermosetting polypropylene.

[0033] Further, the diameter of the hollow ball is 2 mm, the wall thickness of the ball is 0.1 mm, and the true density is 100 kg / m 3 , The hydrostatic pressure strength is 1MPa.

[0034] Further, the true density of the hollow glass microspheres 3 is 100kg / m 3 , the hydrostatic pressure strength is 3MPa, and the diameter is 10 microns.

[0035] Further, the ratio of the total volume of the hollow glass microspheres 3 to the volume of the spherical wall layer 1 is 0.05.

[0036] Further, the density of the spherical wall layer 1 is 350 kg / m 3 , with an elastic modulus of 2.0 GPa.

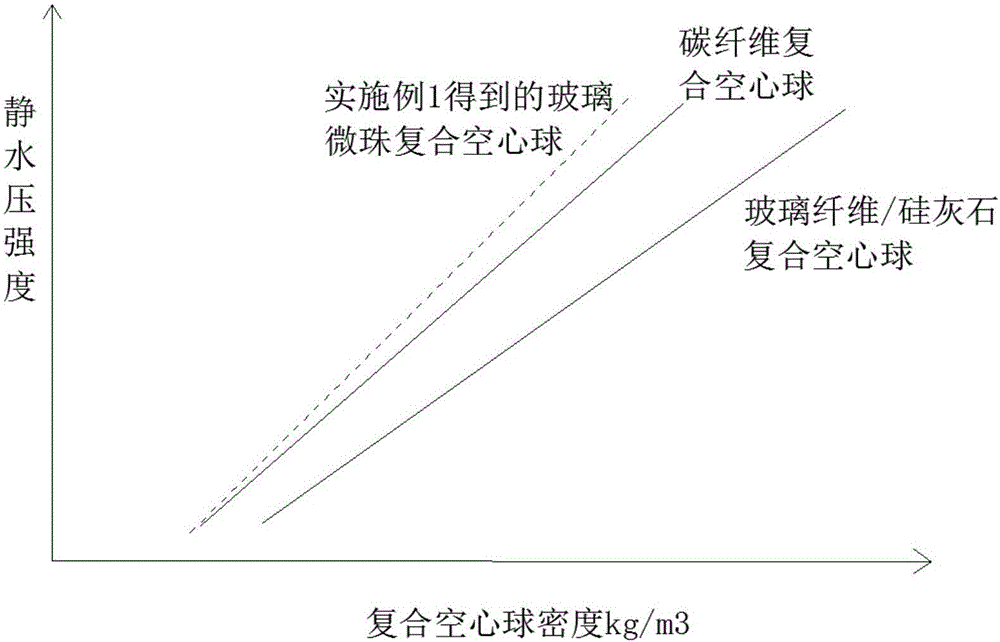

[0037] Depend on figure 2 I...

Embodiment 2

[0049] Such as figure 1 Shown: a hollow ball with a composite material as the wall, including a ball wall layer 1 filled with hollow glass microspheres 3 .

[0050] Further, the ball wall layer 1 is made of thermosetting polymer.

[0051] Further, the thermosetting polymer may be thermosetting epoxy resin, thermosetting polyimide or thermosetting polypropylene.

[0052] Further, the diameter of the hollow ball is 60 mm, the wall thickness of the ball is 5 mm, and the true density is 600 kg / m 3 , The hydrostatic pressure strength is 60 MPa.

[0053] Further, the true density of the hollow glass microspheres 3 is 100kg / m 3 , the hydrostatic pressure strength is 250 MPa, and the diameter is 100 microns.

[0054] Further, the ratio of the total volume of the hollow glass microspheres 3 to the volume of the spherical wall layer 1 is 0.7.

[0055] Further, the density of the spherical wall layer 1 is 1000 kg / m 3 , with an elastic modulus of 15.0 GPa.

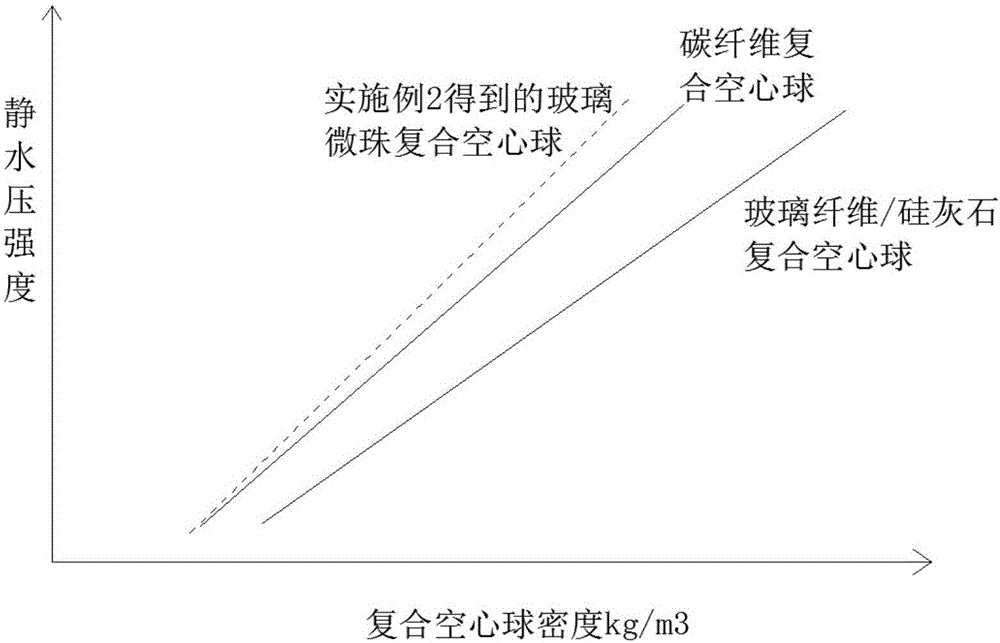

[0056] Depend on imag...

Embodiment 3

[0068] Such as figure 1 Shown: a hollow ball with a composite material as the wall, including a ball wall layer 1 filled with hollow glass microspheres 3 .

[0069] Further, the ball wall layer 1 is made of thermosetting polymer.

[0070] Further, the thermosetting polymer may be thermosetting epoxy resin, thermosetting polyimide or thermosetting polypropylene.

[0071] Further, its diameter is 30 mm, the thickness of the wall layer is 2.5 mm, and the true density is 300 kg / m 3 , The hydrostatic pressure strength is 30 MPa.

[0072] Further, the true density of the hollow glass microspheres 3 is 250kg / m 3 , the hydrostatic pressure strength is 125MPa, and the diameter is 50 microns.

[0073] Further, the ratio of the total volume of the hollow glass microspheres 3 to the volume of the spherical wall layer 1 is 0.3.

[0074] Further, the density of the ball wall layer 1 is 600kg / m 3 , with an elastic modulus of 7 GPa.

[0075] Depend on Figure 4 It is concluded that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| True density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com