Interior wall latex paint with low thermal conductivity

An interior wall latex paint, low thermal conductivity technology, applied in latex paint, coating and other directions, can solve the problems of harmful organic volatile components, the adsorption performance needs to be improved, etc., to achieve good low temperature storage performance, excellent heat resistance, good The effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

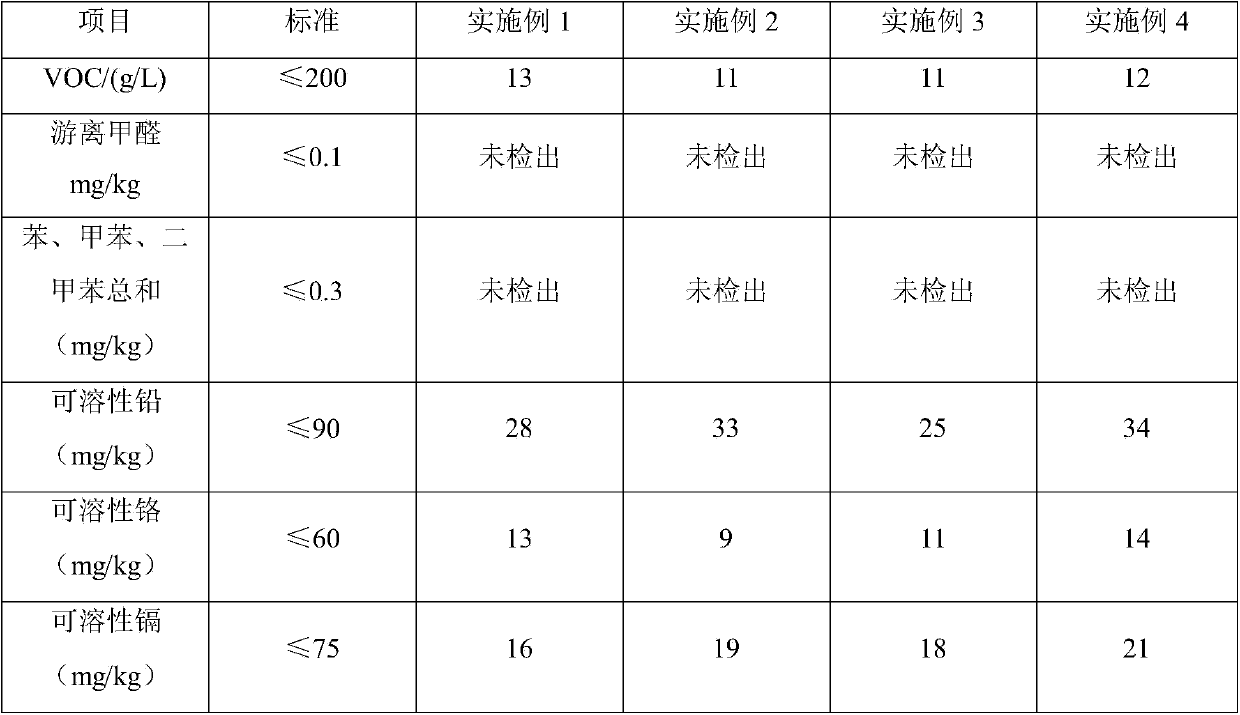

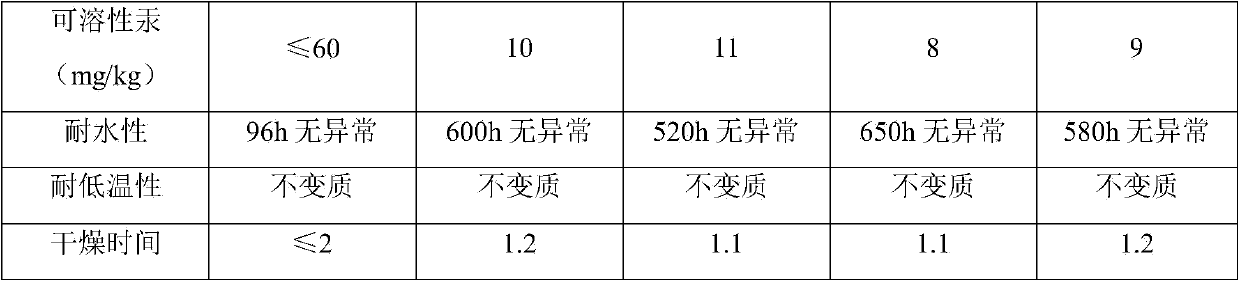

Examples

Embodiment 1

[0014] A low thermal conductivity interior wall latex paint, the raw material formula of the latex paint includes the following components in parts by weight: 4 parts of hydroxyethyl cellulose, 4 parts of barite powder, 2, 2, 4-3 50 parts of methyl-1,3-pentanediol monoisobutyrate, 20 parts of hollow glass microspheres, 12 parts of titanium dioxide, 0.8 parts of nano-copper powder, 3 parts of china clay powder, 3 parts of defoamer Blackburn CF-245, Bactericide and antifungal agent AM-020 1.5 parts, wetting agent SA-80.4 parts, thickener 0.5 parts, dispersant polyacrylic acid sodium salt 6 parts and water 220 parts.

[0015] Its preparation method is as follows:

[0016] Mix the water, hollow glass microspheres, hydroxyethyl cellulose, barite powder and film-forming aids in the formula quantity evenly, add the titanium dioxide, nano-copper powder and china clay powder in the formula quantity to it at a stirring speed of 2200r / min Disperse for 25 minutes, then add the formula am...

Embodiment 2

[0018] A low thermal conductivity interior wall latex paint, the raw material formula of the latex paint includes the following components in parts by weight: 3 parts of hydroxyethyl cellulose, 5 parts of barite powder, 2, 2, 4-3 40 parts of methyl-1,3-pentanediol monoisobutyrate, 30 parts of hollow glass microspheres, 10 parts of titanium dioxide, 1.0 parts of nano-copper powder, 1 part of china clay powder, 5 parts of defoamer Blackburn CF-245, Bactericide and antifungal agent LXE 1 part, wetting agent SA-90.5 parts, dispersant polyacrylic acid sodium salt 5 parts and water 250 parts.

[0019] Its preparation method is as follows:

[0020] Mix the water, hollow glass microspheres, hydroxyethyl cellulose, barite powder and film-forming aids in the formula quantity evenly, add the titanium dioxide, nano-copper powder and china clay powder in the formula quantity to it at a stirring speed of 2000r / min Disperse for 30 minutes, then add the formula amount of defoamer, bactericid...

Embodiment 3

[0022] A low thermal conductivity interior wall latex paint, the raw material formula of the latex paint includes the following components in parts by weight: 5 parts of hydroxyethyl cellulose, 3 parts of barite powder, 2,2,4-3 60 parts of methyl-1,3-pentanediol monoisobutyrate, 10 parts of hollow glass microspheres, 15 parts of titanium dioxide, 0.5 parts of nano-copper powder, 5 parts of china clay powder, 2452 parts of defoamer Blackburn CF-245, Bactericide and antifungal agent LXE 2 parts, wetting agent SA-90.2 parts, dispersant polyacrylic acid sodium salt 8 parts and water 180 parts.

[0023] Its preparation method is as follows:

[0024] Mix the water, hollow glass microspheres, hydroxyethyl cellulose, barite powder and film-forming aids in the formula quantity evenly, add the titanium dioxide, nano-copper powder and china clay powder in the formula quantity to it at a stirring speed of 2500r / min Disperse for 20 minutes, then add the formula amount of defoamer, bacteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com