Fermentation medium and method for improving activity of beta-glucuronidase produced by fungi

A technology of aldolidase enzyme activity and enzyme production medium, which is applied in the biological field and can solve the problems of low enzyme production activity and long enzyme production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

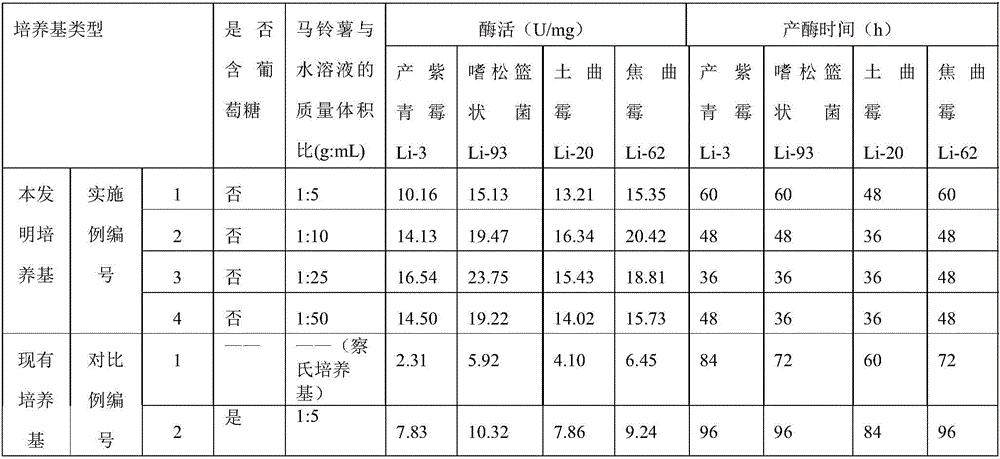

Examples

Embodiment 1

[0039] Embodiment 1, adopting No. 1 fermentation enzyme production medium of the present invention to carry out fermentation production enzyme

[0040] Penicillium purpurea Li-3, T. pinophilum Li-93, Aspergillus terreus Li-20, and Aspergillus pyrogenus Li-62 were respectively fermented to produce enzymes. The specific operation process was as follows:

[0041] Inoculate the spores of Penicillium purpurea Li-3, T. pinophilum Li-93, Aspergillus terreus Li-20 and Aspergillus pylorus Li-62 in potato dextrose liquid medium respectively, and cultivate them on a shaker at 30°C and 200rpm 48h. Then insert 5% of the inoculum into the medium of the secondary seed liquid, culture on a shaker at 30° C. and 200 rpm for 24 hours to obtain the secondary seed liquid of each fungus mentioned above.

[0042] Secondary seed liquid culture medium: Weigh 200g of peeled potatoes, add 800mL of water, boil for about 30 minutes, filter through gauze, add 1g of glucose, dissolve and add water to 2000m...

Embodiment 2

[0045] Embodiment 2, adopt No. 2 fermentation enzyme production medium of the present invention to carry out fermentation production enzyme

[0046] Penicillium purpurea Li-3, T. pinophilum Li-93, Aspergillus terreus Li-20, and Aspergillus pyrogenus Li-62 were respectively fermented to produce enzymes. The specific operation process was as follows:

[0047] Inoculate the spores of Penicillium purpurea Li-3, T. pinophilum Li-93, Aspergillus terreus Li-20 and Aspergillus pylorus Li-62 in potato dextrose liquid culture medium respectively, at 30°C, 200rpm Incubate on a shaker for 48 hours. Then insert 5% of the inoculum into the medium of the secondary seed liquid, culture on a shaker at 30° C. and 200 rpm for 24 hours to obtain the secondary seed liquid of each fungus mentioned above.

[0048] Secondary seed liquid medium: Weigh 200g of peeled potatoes, add 800mL of water, boil for about 30 minutes, filter through gauze, add 5g of glucose, dissolve and add water to 2000mL, natu...

Embodiment 3

[0051] Embodiment 3, adopt No. 3 fermentation enzyme production medium of the present invention to carry out fermentation production enzyme

[0052] Penicillium purpurea Li-3, T. pinophilum Li-93, Aspergillus terreus Li-20, and Aspergillus pyrogenus Li-62 were respectively fermented to produce enzymes. The specific operation process was as follows:

[0053] Inoculate the spores of Penicillium purpurea Li-3, T. pinophilum Li-93, Aspergillus terreus Li-20 and Aspergillus pylorus Li-62 in potato dextrose liquid culture medium respectively, at 30°C, 200rpm Incubate on a shaker for 48 hours. Then inoculated in the secondary seed liquid culture medium with 5% inoculum amount, cultivated on a shaker at 30° C. and 200 rpm for 24 hours to obtain the secondary seed liquids of the above-mentioned fungi.

[0054] Secondary seed liquid medium preparation method: 200g of peeled potatoes, add 1000mL of water, boil for about 30 minutes, filter through gauze, add 8g of glucose, dissolve and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com