A manufacturing method of graphite-containing high-speed steel combined nesting composite roll

A composite roll and high-speed steel technology, which is applied in the field of high-speed steel combined-sleeve composite roll manufacturing, can solve the problems affecting the surface quality of the rolled material, increase the friction coefficient of the roll, and the linear velocity difference, so as to improve the comprehensive use performance and improve the rolling speed. surface quality, the effect of reducing the roughness level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

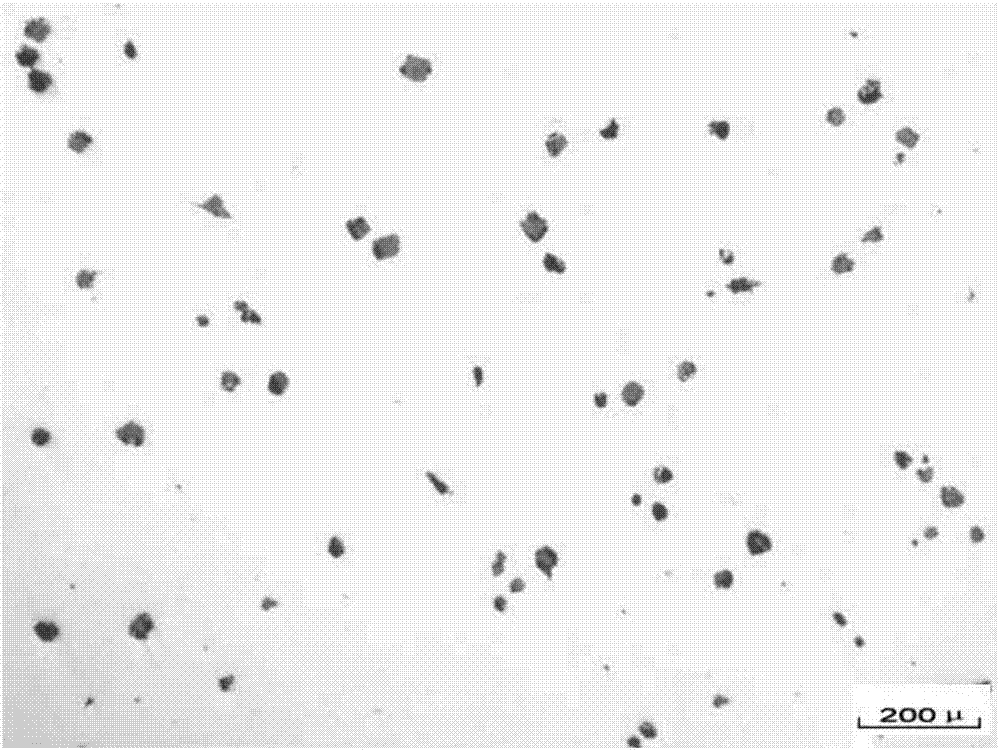

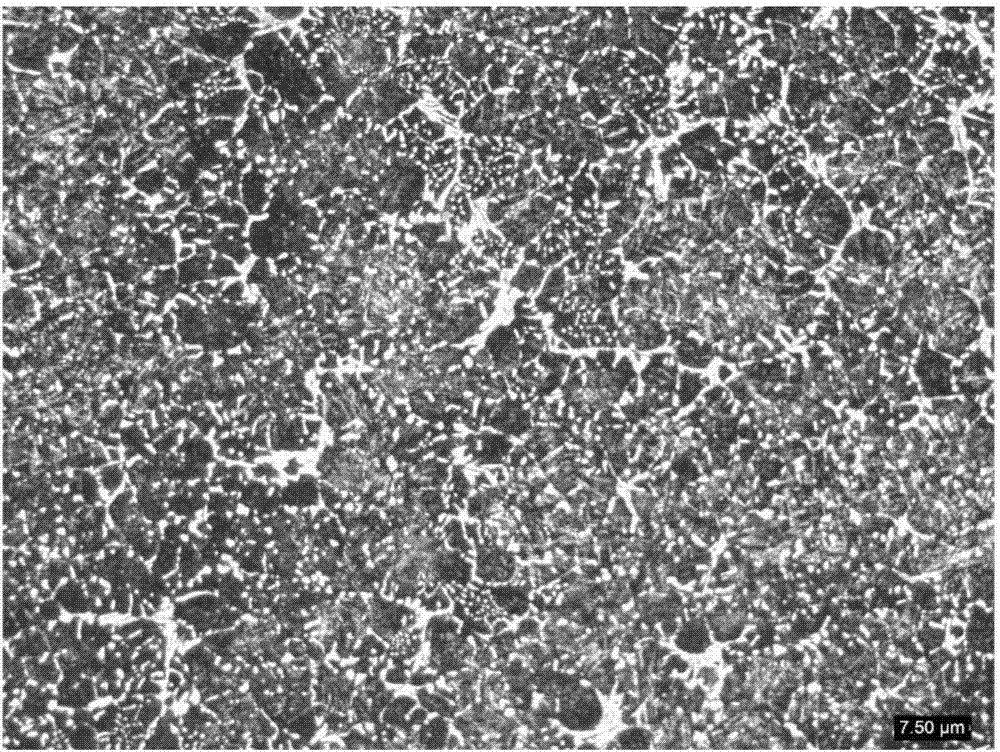

[0032] Embodiment 1 A kind of manufacturing method of the outer shell (working layer) of the centrifugal high-speed steel roll that contains graphite

[0033] 1) The chemical composition of the outer layer is composed by mass fraction (%): C 2.0-3.0%, Si 0.8-2.5%, Mn 0.2-1.0%, 0<P≤0.05%, 0<S≤0.02%, Cr 3-10 %, Ni 0.5-3.5%, Mo 2.5-6.0%, V 3-8%, 0<W≤10%, 0<B≤0.5%, N 60-500PPM, prepare the charge;

[0034] 2) Using intermediate frequency furnace for smelting;

[0035] 3) Si content before furnace control = Si content of finished product - 0.35%; V content before furnace control = V content of finished product - 0.25%;

[0036] 4) Measure the liquid and solidus temperature (T L , T S );

[0037] 5) Control the furnace temperature T 出 = liquidus temperature of the outer metal liquid (T L外 )+(240~300)℃;

[0038] 6) Metamorphic treatment of carbon, nitrogen and borides out of the furnace:

[0039] During the furnace discharge process, along with the metal flow, vanadium alloy ...

Embodiment 2

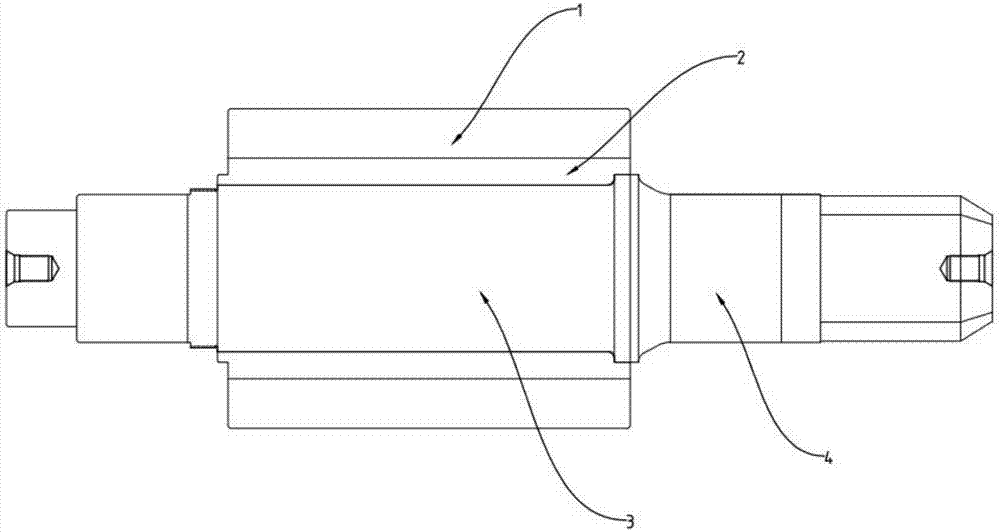

[0057] Embodiment 2 A kind of graphite-containing high-speed steel sleeve, shaft assembly roll manufacturing method

[0058] Prepare the outer cylinder by dynamic centrifugal casting according to Steps 1) to 9) of Example 1, and carry out composite casting of the middle layer metal according to Step 10) of Example 1, and through corresponding heat treatment, thermal processing and mechanical cold processing, and the previously prepared As for the mandrel material, mechanical interference assembly is carried out by using the bushing composite hot-packing method to obtain a combined assembly roll;

[0059] 11) Mandrel preparation for shaft sleeve combination shrink fitting:

[0060] Mandrel material for shaft sleeve combination heat-fitting: it can be processed by C 0.2-1.0% cast steel material according to the mandrel drawing; semi-finishing according to the requirements of the assembly drawing.

[0061] 12) Shaft and sleeve assembly

[0062] According to the finishing drawin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com