Selective catalytic reduction (SCR) after-treatment system urea supply device and treatment method

A technology of supply device and urea, which is applied in the direction of electric control of exhaust treatment device, exhaust treatment, noise reduction device, etc., can solve the problems of increasing cost and hindering development and promotion, and achieves reduced production cost, good energy saving, and reduced consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

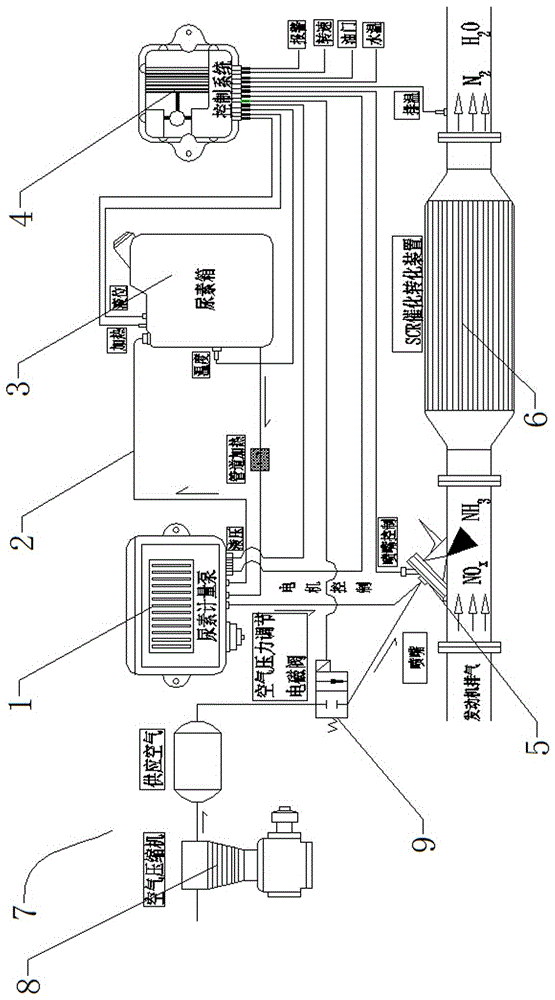

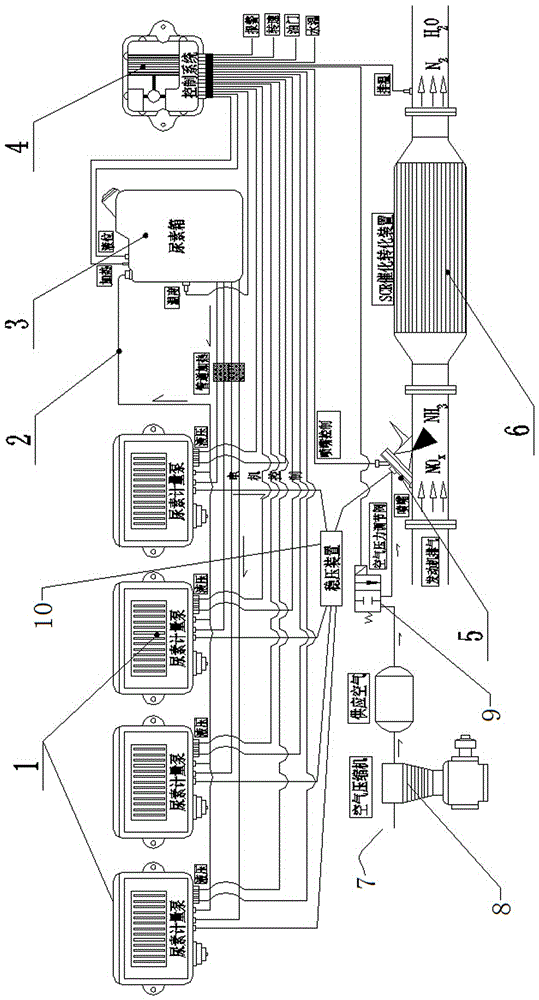

[0037] Examples such as figure 2 As shown, a urea supply device for an SCR post-treatment system includes a urea tank 3. The urea tank 3 is connected in parallel with at least two urea metering pumps 1 through a wiring harness and a pipeline 2. According to changes in working conditions, each urea metering pump 1 can be independently work, a plurality of urea metering pumps 1 can also work partially or completely.

[0038] The urea supply device also includes an SCR catalytic conversion device 6, the SCR catalytic conversion device 6 is connected with a nozzle 5, and two or more urea metering pumps 1 are respectively connected with the nozzle 5 through pipelines.

[0039] The two or more urea metering pumps 1 are connected to the nozzles 5 through a pressure stabilizing device 10 to ensure consistent pipeline pressure and reliable and accurate metering and injection.

[0040] Each urea metering pump 1 is connected with an automatic start-stop switch.

[0041] The injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com