Coupler with axis adjusting deviation

A coupling and deviation technology, applied in the field of couplings, can solve the problems of increased milling cost and low milling efficiency, and achieve the effects of large displacement range, elimination of additional load, and large-scale alignment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

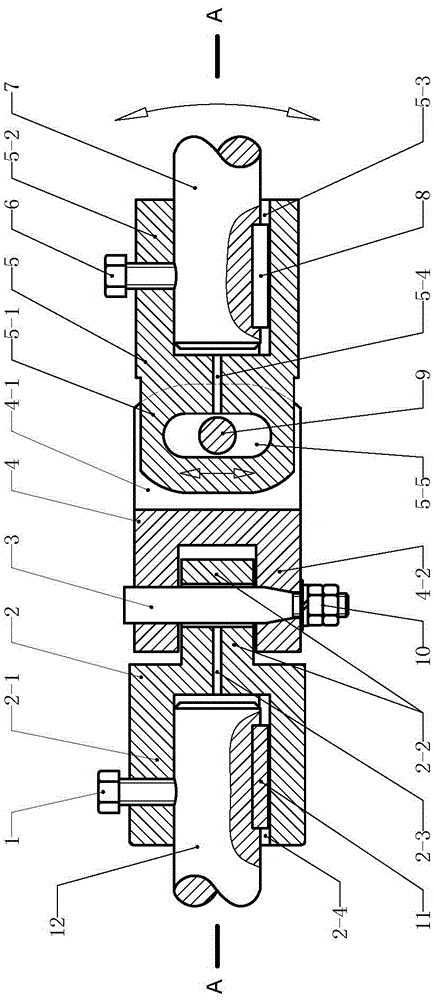

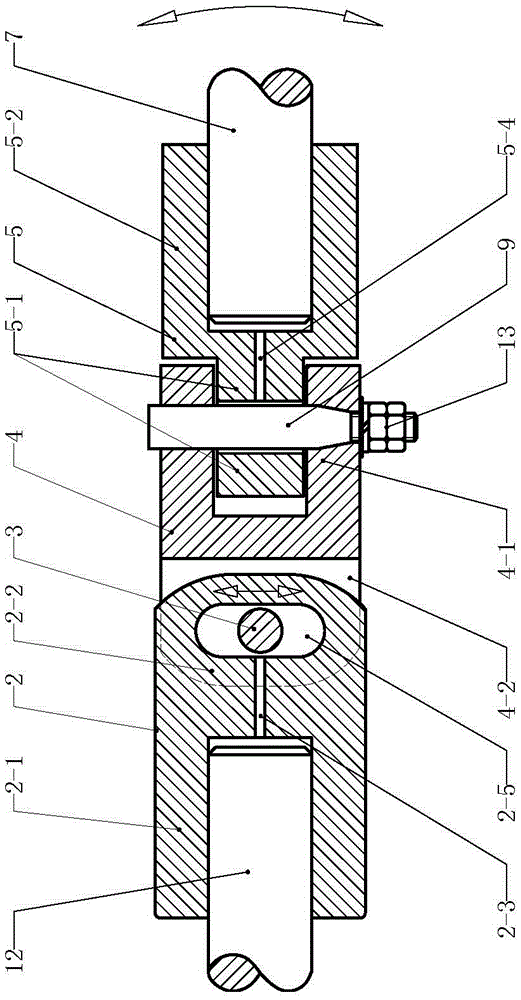

[0014] Example Figure 1-2 In the shown embodiment, the shaft coupling with adjustable axis deviation is mainly composed of two shaft couplings with the same structure and an intermediate connecting piece 4, wherein one end of the shaft coupling is a shaft seat, and the other end of the shaft coupling is a The centering head has a shaft hole in the center of the shaft seat, a keyway on the wall of the shaft hole, and a locking screw on the shaft seat. It is a radial strip-shaped hole structure; the intermediate connecting piece 4 is composed of two transfer forks with opposite directions, and the space between the two fork lobes of the transfer fork is a straight notch, and the two transfer forks facing away The heads are perpendicular to each other, and there are a pair of pin holes on the two opposite transfer yokes; the self-aligning head 2-2 of the first coupling is inserted into the notch of the left transfer yoke 4-2 of the intermediate connector 4, and the second A pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com