Test method for simulating combined load effect of explosive shock waves and high-speed fragment groups

A technology of combined load and test method, which is applied to the measurement of blasting force, ammunition test, offensive equipment, etc., can solve the problems of long design and production cycle, high grid density, and low test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

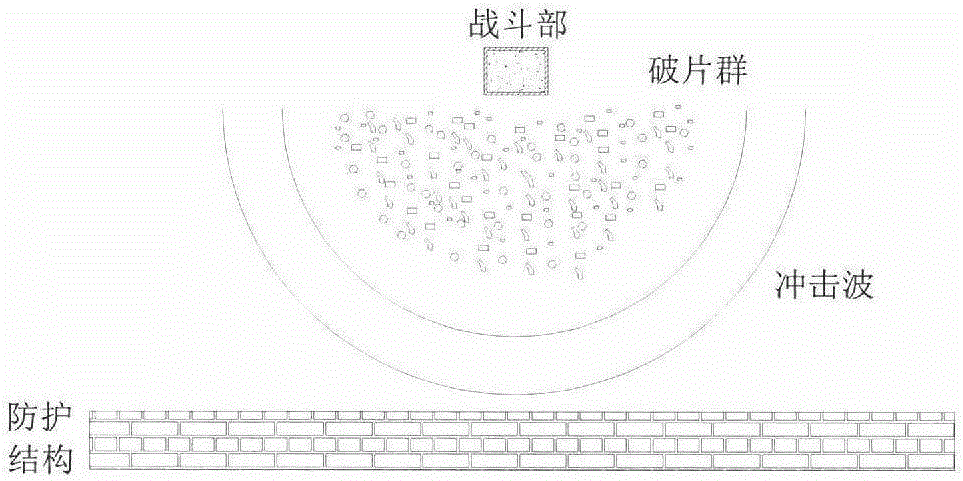

[0081] Embodiment 1. This example is a test method for simulating the combined load of the explosion shock wave and the high-speed fragment group that a certain cylindrical warhead explodes in the air, such as figure 2 As shown, it is a schematic diagram of the fragments flying after the explosion of the warhead;

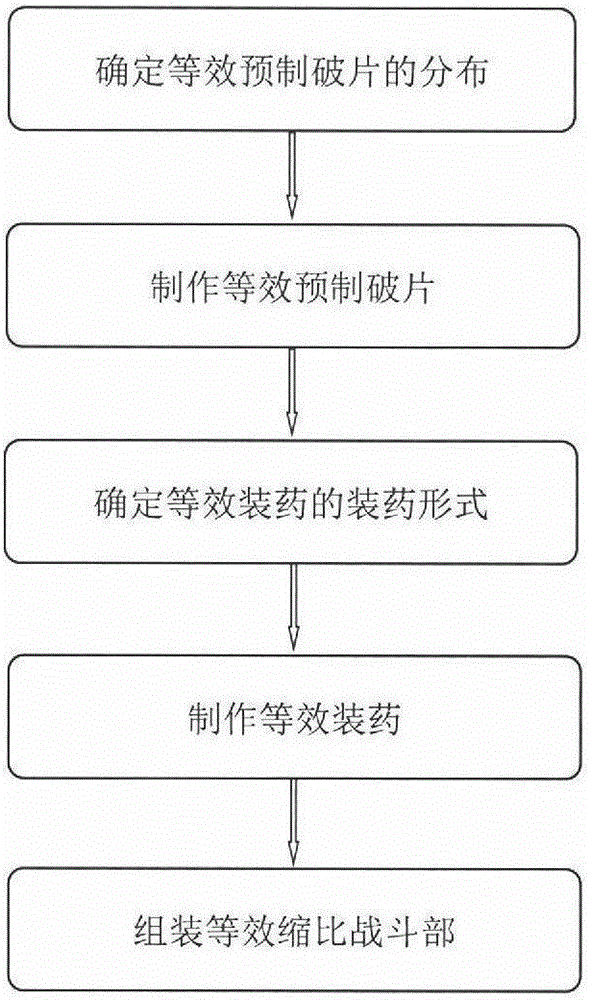

[0082] Include the following steps:

[0083] (1) Determine the distribution steps of equivalent prefabricated fragments, including the following sub-steps:

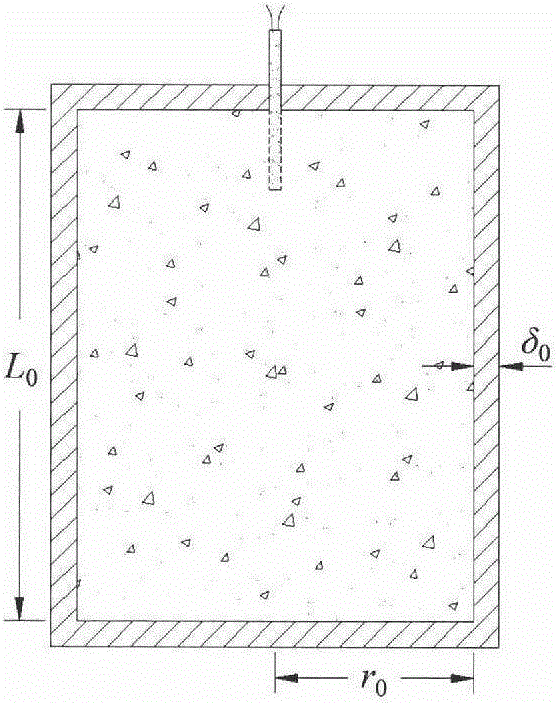

[0084] (1.1) Determine the scale warhead model size;

[0085] The defense target warhead is cylindrical, the charge is TNT charge, and the charge density is 1610kg / m 3 , the charge length is 0.50m, and the charge radius is 0.175m; the warhead shell material is 45# steel, and the shell thickness is 0.02m;

[0086] According to the requirements of similar theory and test conditions, the scale ratio of the scaled model is determined to be 1:5, that is, the scaled warhead is still cylindrical, and the charge is...

Embodiment 2

[0114] Embodiment two, this example is the test method for simulating the explosion shock wave and high-speed fragment joint load that certain spherical warhead air explosion produces, as figure 2 As shown, it is a schematic diagram of the fragments flying after the explosion of the warhead;

[0115] Include the following steps:

[0116] (1) Determine the distribution steps of equivalent prefabricated fragments, including the following sub-steps:

[0117] (1.1) Determine the scale warhead model size;

[0118] The defense target warhead is spherical, the charge is Octo gold charge, and the charge density is 1890kg / m 3 , the charge radius is 0.2m; the warhead shell material is 30CrMnSiNi2A, and the shell thickness is 0.02m;

[0119] According to the requirements of similar theory and test conditions, the scale ratio of the scaled model is determined to be 1:4, that is, the scaled warhead is still spherical, and the charge is made of octogold. The profile of the spherical war...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com